Tower type sewage purification device based on spiral structure

A technology of sewage purification and spiral structure, which is applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems of difficult replacement and cleaning of fillers, small contact area, and low purification efficiency. Achieves the effect of easy cleaning, increased area, and accelerated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

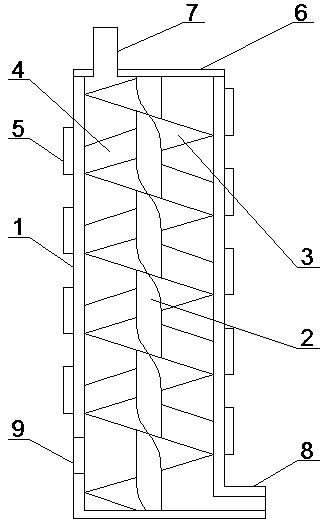

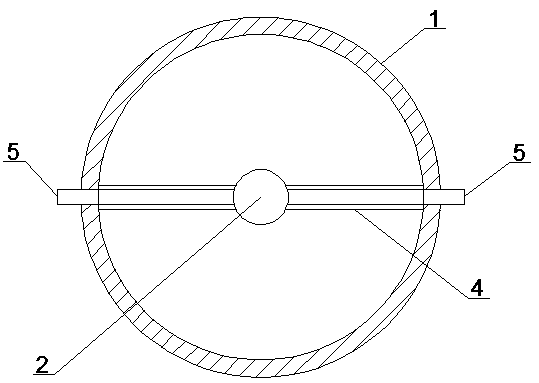

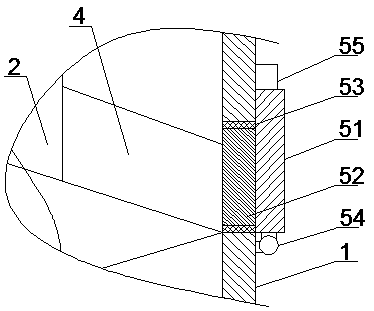

[0017] Such as figure 1 and figure 2 A tower-type sewage purification device based on a spiral structure is shown, including a tower body 1, which is a cylindrical barrel-shaped structure with an upper end opening, and a central axis 2 is arranged in the tower body 1, and the central axis 2 is located on the axis of the tower body 1. position, the outer wall of the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com