A kind of preparation method of graphene oxide nanometer material

A nanomaterial and graphene technology, which is applied in the field of nanomaterials, can solve the problems of inability to obtain nanoscale flake GO materials, difficult to toughen, and poor dispersibility, so as to inhibit the formation of titanium dioxide monomer particles and prevent aggregation and precipitation. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

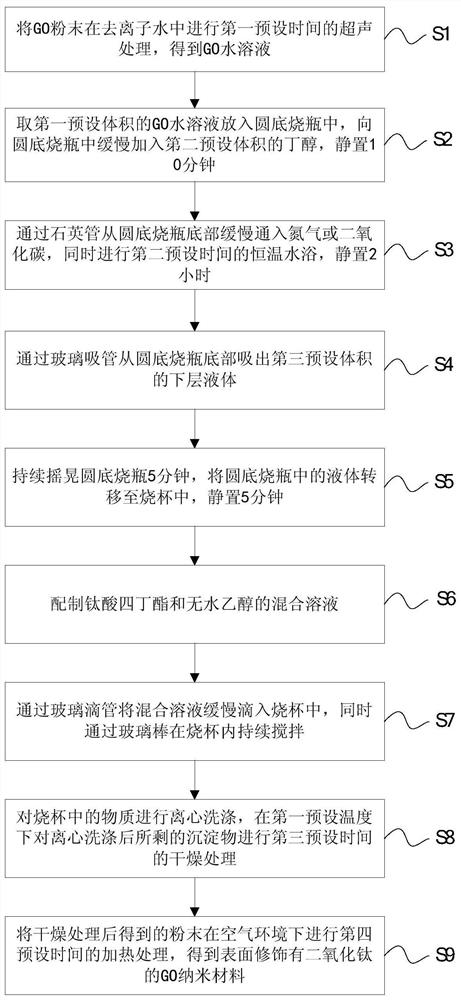

[0043] Such as figure 1 Shown, a kind of preparation method of graphene oxide nano material comprises:

[0044] S1. Ultrasonic treatment of GO powder in deionized water for a first preset time to obtain GO aqueous solution;

[0045] S2. Put the GO aqueous solution of the first preset volume into the round bottom flask, slowly add the second preset volume of butanol into the round bottom flask, and let it stand for 10 minutes;

[0046] S3. Slowly inject nitrogen or carbon dioxide from the bottom of the round-bottomed flask through a quartz tube, and simultaneously carry out a constant temperature water bath for the second preset time, and let stand for 2 hours;

[0047] S4, suck out the lower layer liquid of the third predetermined volume from the bottom of the round bottom flask through the glass straw;

[0048] S5, continue to shake the round-bottomed flask for 5 minutes, transfer the liquid in the round-bottomed flask to the beaker, and let stand for 5 minutes;

[0049] S...

Embodiment 1

[0061] (1) Ultrasonic GO powder in deionized water for 30 minutes (ultrasonic power 180W) to prepare GO aqueous solution, GO content is 0.5-2mg / mL (within this content range, GO can be fully dispersed in water, there is no multi-layer GO or oxidised graphite).

[0062] (2) Take the above GO aqueous solution with a volume of V1=300-500mL, store it in a round bottom flask with a capacity of 1000mL, slowly add 200mL of butanol, and let it stand for 10 minutes. In this flask, butanol is insoluble in water and will be in the upper layer of the solution; the GO aqueous solution is in the lower layer, and the volume of the GO aqueous solution is nearly half of the volume of the flask, and the area of the layered interface between the GO solution and butanol is relatively large.

[0063] (3) Slowly feed nitrogen or carbon dioxide from the bottom of the flask through a quartz tube, and simultaneously carry out a constant temperature water bath at 50-80° C. for 2 hours. After that, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com