Paper roll winding system and paper roll winding method

A paper roll and paper web technology, applied in the field of paper roll winding system, can solve the problems of poor winding effect, ridges and dead lines on the surface of the paper roll, etc., so as to improve the winding effect and reduce the appearance of paper defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

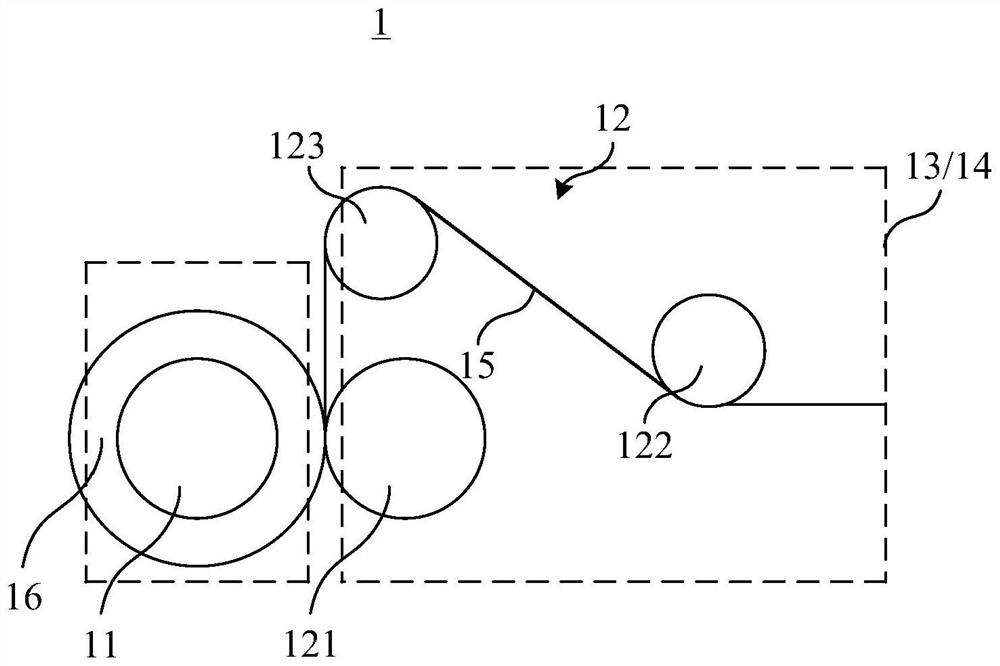

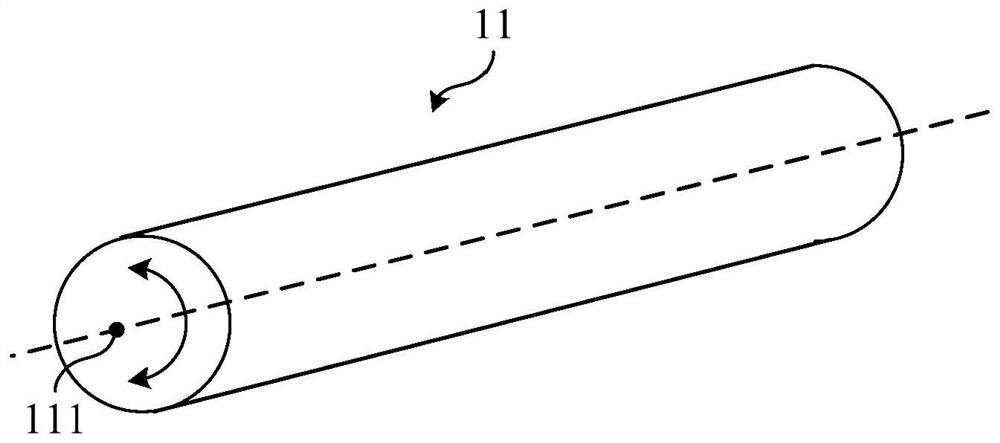

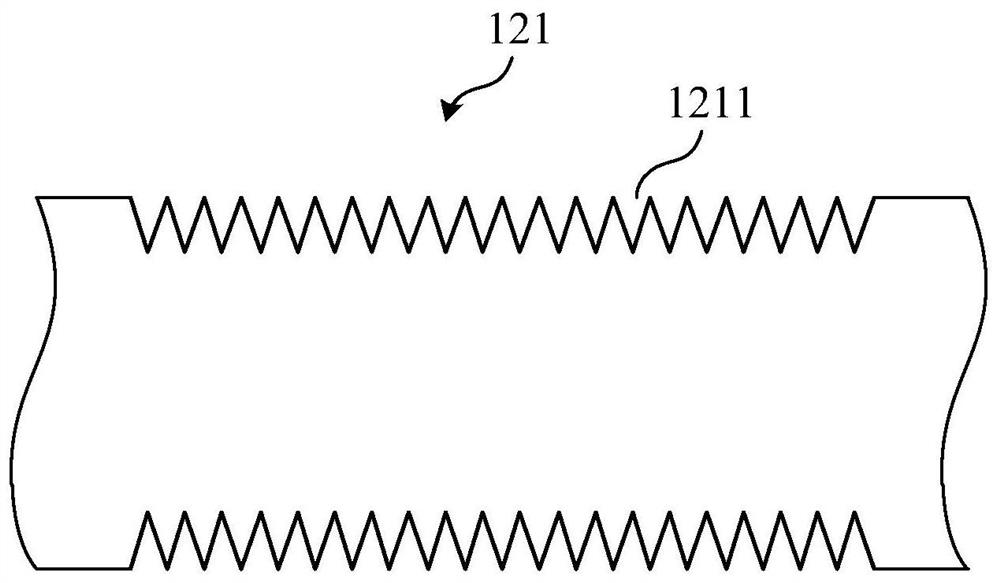

[0031] In order to solve the technical problem of poor winding effect of the existing paper roll, the present invention provides a paper roll winding system, the paper roll winding system includes a paper roll and a functional roll assembly, and the paper roll and the functional roll assembly One end of the same side is connected to the operation platform, and the other end of the same side is respectively connected to the transmission platform; the functional roller assembly includes a pressing roller, a stretching roller and a reverse acting roller, and the axial directions of the winding roller, pressing roller and reverse acting roller are parallel to each other The winding roll can rotate around its central axis to take up the paper roll, the pressure roll can press agains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com