An all-round floating fuel supply system and its operation method

A supply system and all-round technology, applied in the field of all-round floating fuel supply system, can solve the problems of high cost requirements of oil transport ships, high power requirements of external transport pumps, and easy collisions, etc., so as to improve collision and relative lift. The effect of sinking motion and other disturbances, meeting safety and applicability requirements, and quickly disengaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

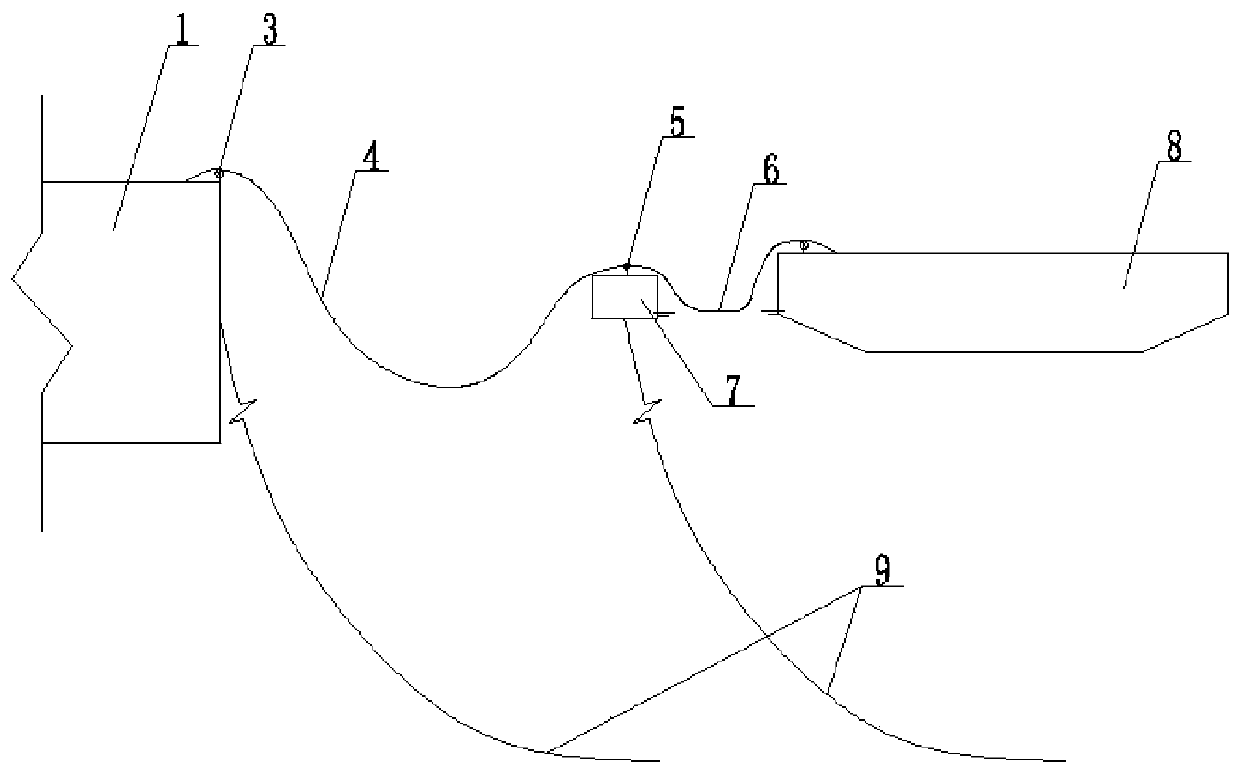

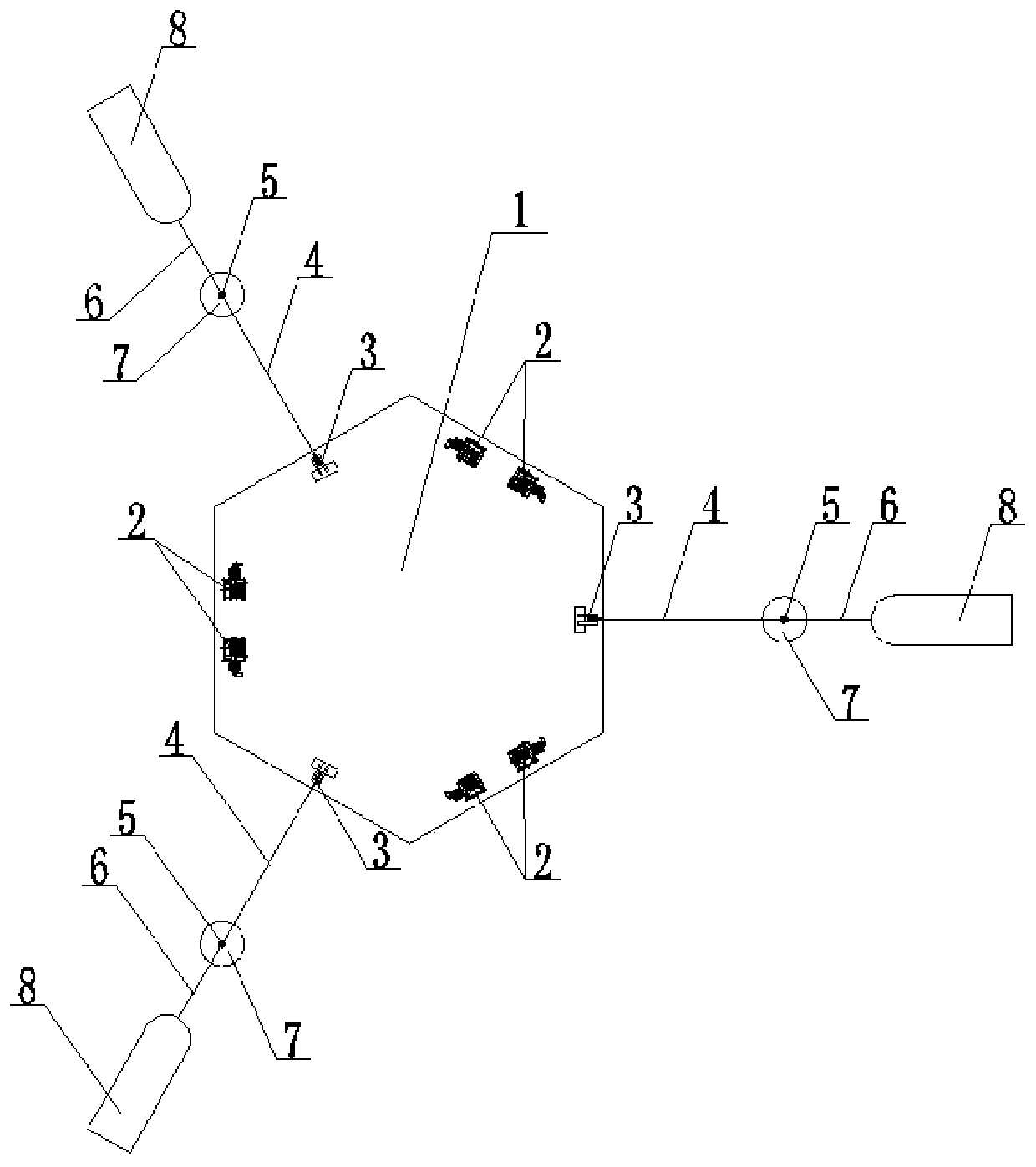

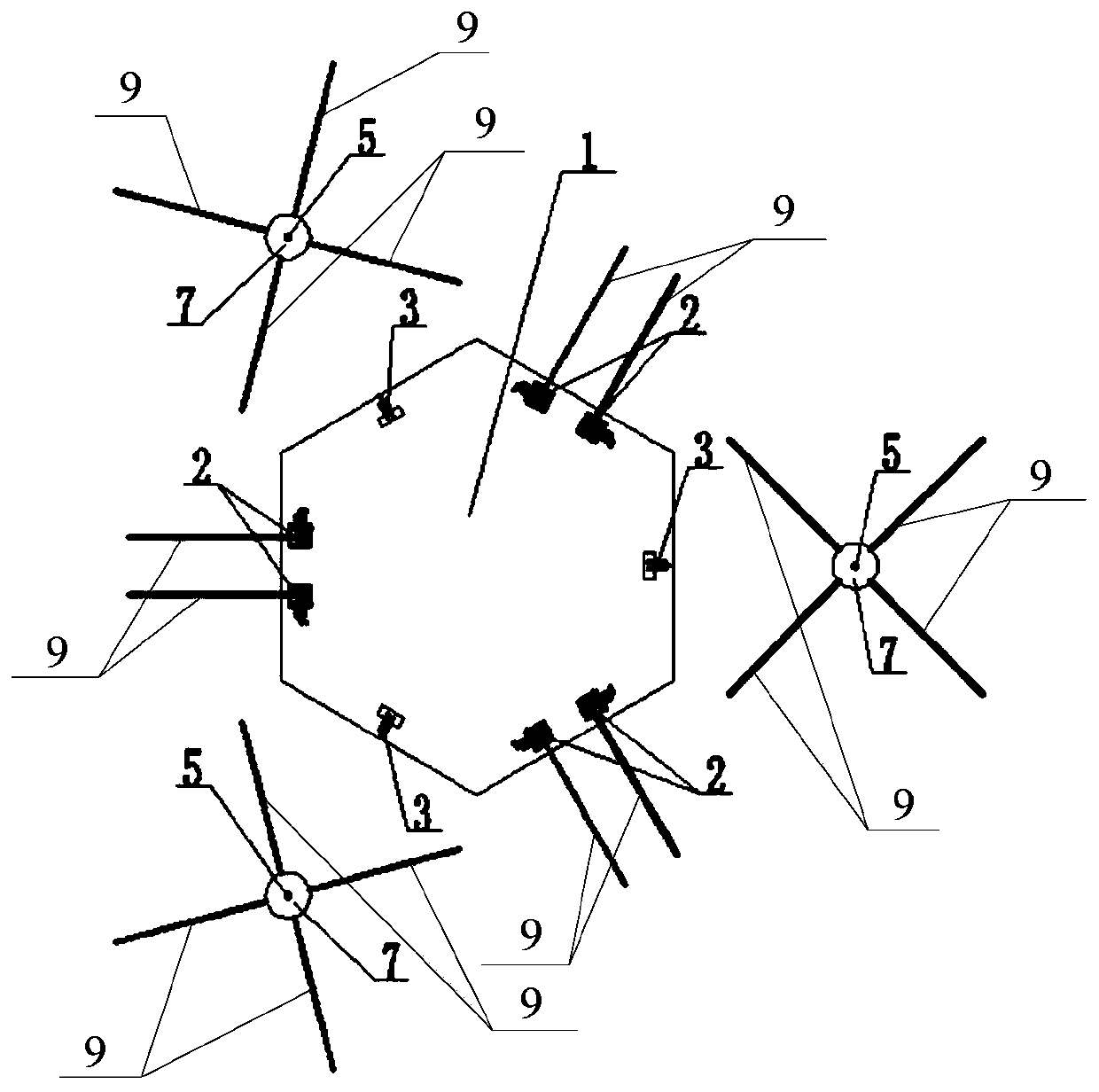

[0028] See figure 1 , figure 2 , the floating fuel supply system device of the present invention includes a floating fuel supply platform 1, an oil pipeline 4, a buoy 7, an anchor chain 9, and a floating hose 6,

[0029] The side of the floating fuel supply platform 1 is provided with a winch 2 . An anchor chain 9 protrudes from the winch 2 to fix the floating fuel supply platform 1 on the seabed. Above the floating fuel supply platform 1, a conduit 3 is also provided at a position different from the side where the winch 2 is provided. The conduit 3 includes a projecting end towards the outside of the floating refueling platform 1 . An oil delivery pipe 4 is wound on the protruding end of the conduit 3 . A buoy 7 is also included, and the buoy 7 is located in the direction facing the outer side of the projecting end of the conduit 3 . The direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com