Automatic material leakage device applied to the unloading of feed transport vehicles

A technology for transporting vehicles and movable devices, which is applied to vehicles with screw conveyors and other directions, can solve the problems of increased work intensity, decreased work efficiency, and increased difficulty in screw rotation, and achieves the effect of quick connection and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

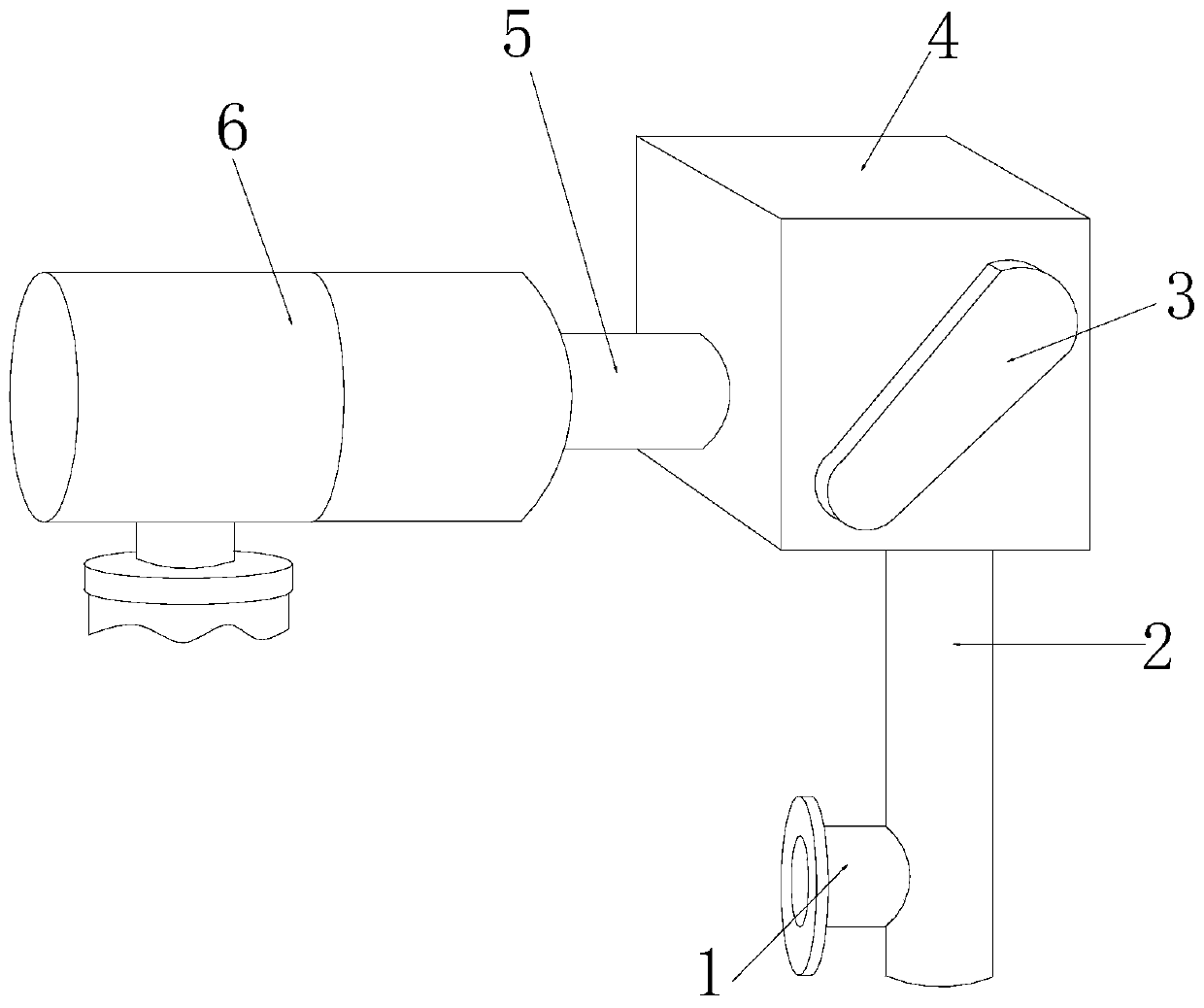

[0023] see figure 1 and figure 2 , the present invention provides an automatic material leakage device applied to the unloading of feed transport vehicles. The feed pipe 1 is located on the left end face of the conveying pipe 2 while the two are connected through through. The power cabin 4 and the conveying pipe 2 are perpendicular to each other and fixedly installed on the upper surface of the conveying pipe 2. The transmission frame 3 is arranged on the power The front end face of the cabin 4 is fixedly connected with the power cabin 4 at the same time, the winch 5 and the power cabin 4 are perpendicular to each other and fixedly installed on the left side of the power cabin 4, and the intelligent leakage device 6 is located on the winch The two left end surfaces of 5 are mechanically connected, and the inside of the auger frame 5 is provided with a helical worm, and the helical worm can squeeze out the internal feed during rotation.

[0024] see image 3 , the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com