Construction Method of Negative Bending Moment Stretching Groove of Prefabricated Beam

A construction method and technology of negative bending moment, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of concrete slurry leakage, excessive friction coefficient, neglected construction quality, etc., and achieve accurate anchorage pre-embedding and high molding quality. , the effect of rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

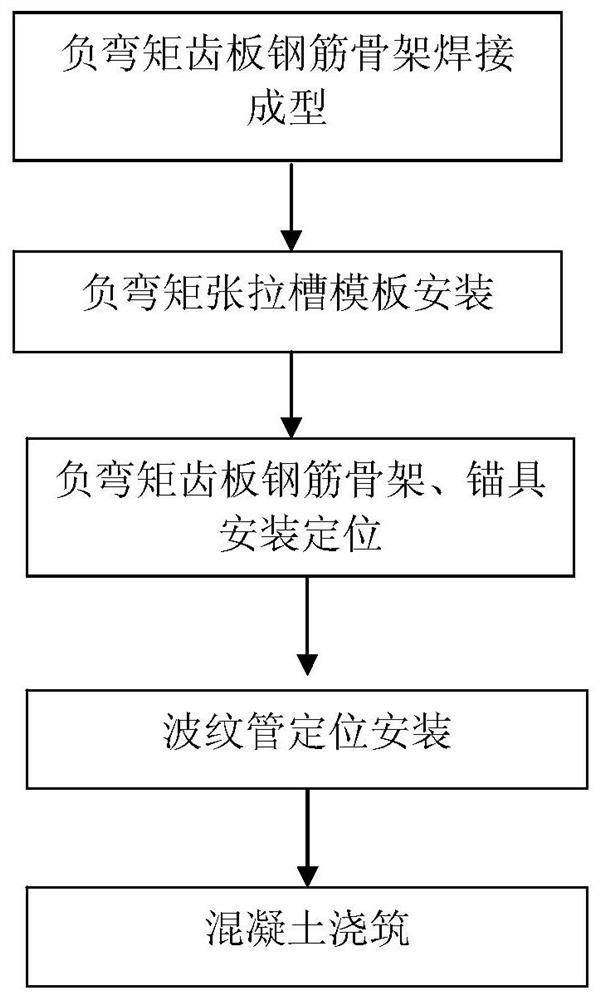

[0021] The construction method of the prefabricated beam negative moment tension groove includes the following steps:

[0022] (1) Negative bending moment tooth plate steel skeleton welding and forming: According to the design requirements, a number of ring bars are integrally pierced and bound on the prefabricated beam reinforcement layer at a distance of 2m, and then welded and fixed to form a prefabricated beam reinforcement skeleton;

[0023] (2) Negative bending moment tension groove formwork installation: put the prefabricated beam steel skeleton into the mold as a roof reinforcement, and then position and insert the formwork around the ring reinforcement according to the design requirements to form a negative bending with a specification of 0.8m×0.8m Rectangular stretching groove; the template described in step (2) is the special template for assembled double-layer comb-shaped stretching groove;

[0024] (3) Installation and positioning of negative moment tooth plate st...

Embodiment 2

[0028] The construction method of the prefabricated beam negative moment tension groove is characterized in that it comprises the following steps:

[0029] (1) Negative bending moment tooth plate steel skeleton welding and forming: According to the design requirements, a number of ring bars are integrally pierced and bound on the prefabricated beam reinforcement layer at a distance of 2.5m, and then welded and fixed to form a prefabricated beam reinforcement skeleton;

[0030] (2) Negative bending moment tension groove formwork installation: put the prefabricated beam steel skeleton into the mold as a roof reinforcement, and then position and insert the formwork around the ring reinforcement according to the design requirements to form a negative bending with a specification of 0.8m×0.8m Rectangular stretching groove; the template described in step (2) is the special template for assembled double-layer comb-shaped stretching groove;

[0031] (3) Installation and positioning of...

Embodiment 3

[0035] The construction method of the prefabricated beam negative moment tension groove is characterized in that it comprises the following steps:

[0036] (1) Negative bending moment tooth plate steel skeleton welding and forming: According to the design requirements, a number of ring bars are integrally pierced and bound on the prefabricated beam reinforcement layer at a distance of 3m, and then welded and fixed to form a prefabricated beam reinforcement skeleton;

[0037] (2) Negative bending moment tension groove formwork installation: put the prefabricated beam steel skeleton into the mold as a roof reinforcement, and then position and insert the formwork around the ring reinforcement according to the design requirements to form a negative bending with a specification of 0.8m×0.8m Rectangular stretching groove; the template described in step (2) is the special template for assembled double-layer comb-shaped stretching groove;

[0038](3) Installation and positioning of ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com