Medicinal material slicing machine based on improving slicing efficiency

A technology of slicer and medicinal materials, which is applied in metal processing and other directions, can solve the problems of low efficiency, achieve the effect of increasing cutting speed, increasing force, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

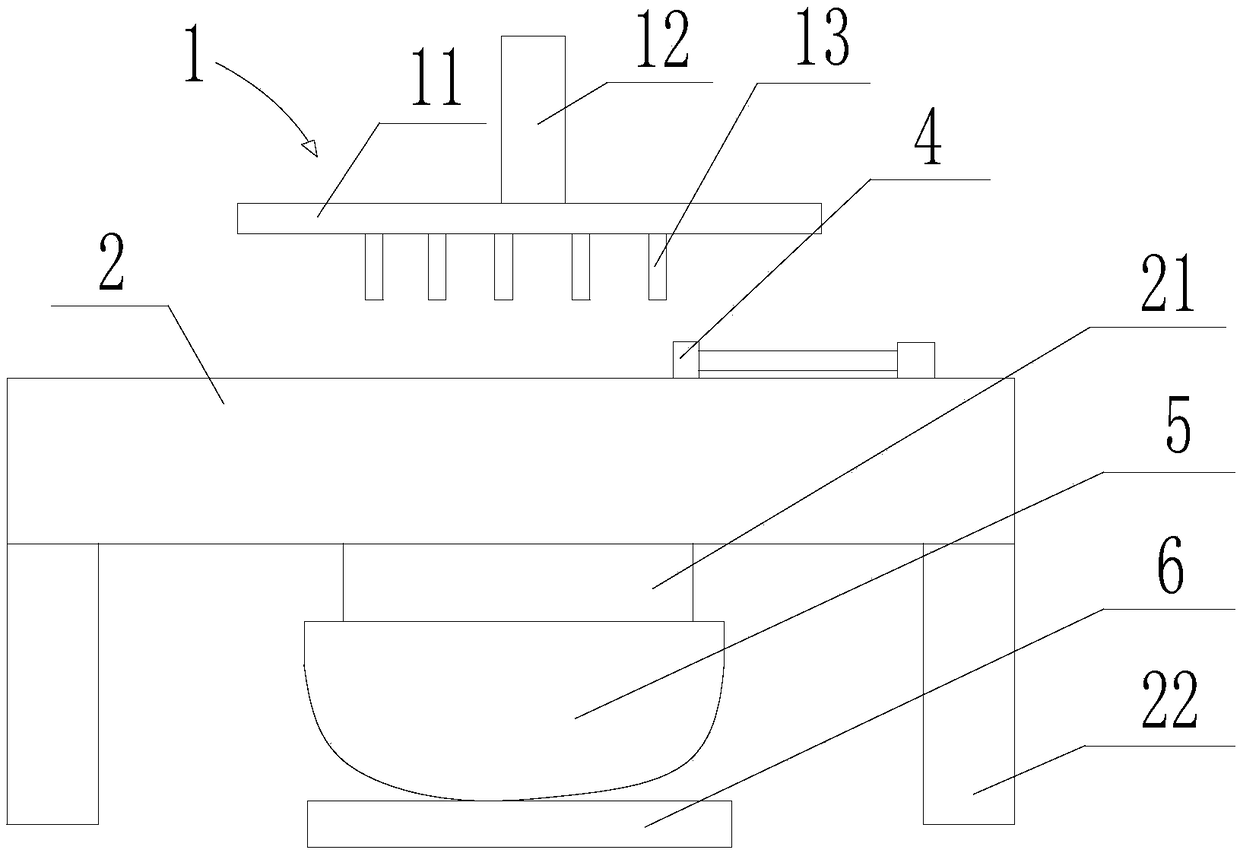

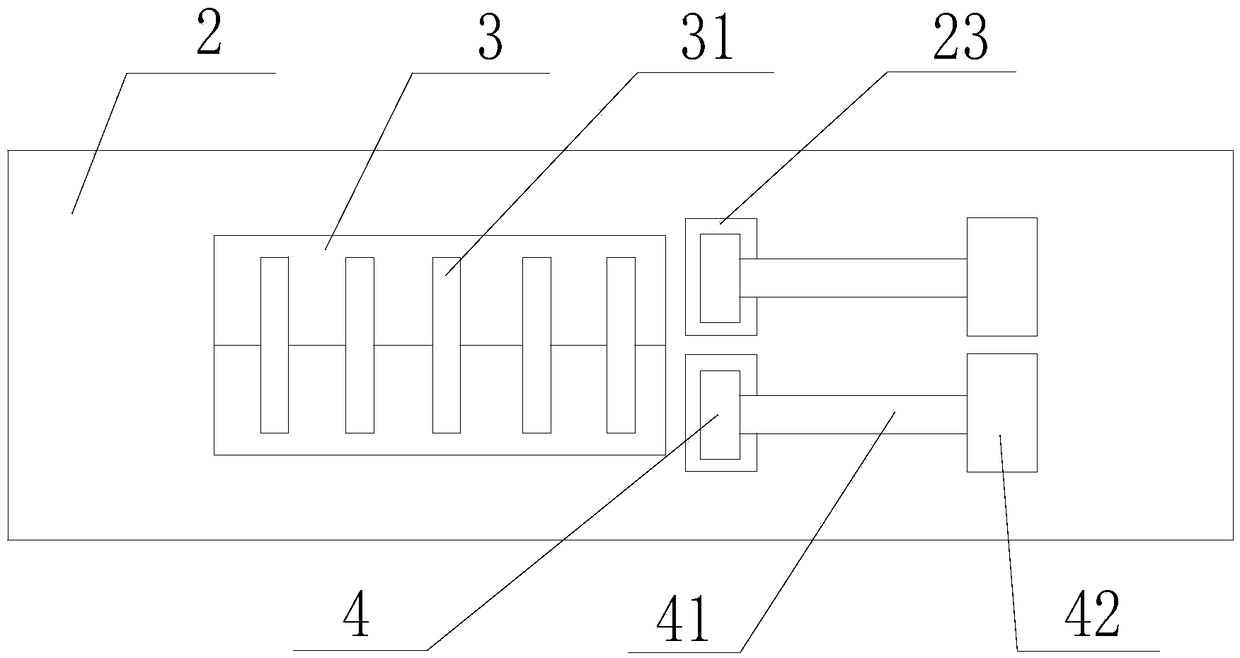

[0030] Such as figure 1 , figure 2 As shown, the medicinal material slicer based on improving slicing efficiency includes a cutting mechanism 1 and a cutting table 2, the bottom of the cutting table 2 is provided with a foot 22, and the cutting table 2 is provided with a first through groove, and the first The bottom of the slot is rotatably provided with 2 support plates 3, and the support plates 3 are controlled by a stepper motor to rotate 90° to realize horizontal or vertical placement. When the 2 support plates 3 are placed horizontally, the 2 support plates 3 will just The first through groove is closed, and a plurality of gaps 31 are set on the support plate 3. When the two support plates 3 are placed horizontally, the gaps 31 provided on the two support plates 3 communicate, and the cutting table 2 is provided with two The clamping part 4 matched with the support plate 3, the clamping part 4 is used to fix the end of the medicinal material, the cutting mechanism 1 is...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, and also includes a weighing device 6, and the storage bag 5 is placed on the weighing device 6; the upper end surface of the support plate 3 is set as a threaded surface; the cutting of the blade 13 The end is a sawtooth structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com