Full-automatic screwing machine

A screw-driving machine, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to adapt to multiple models, single mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

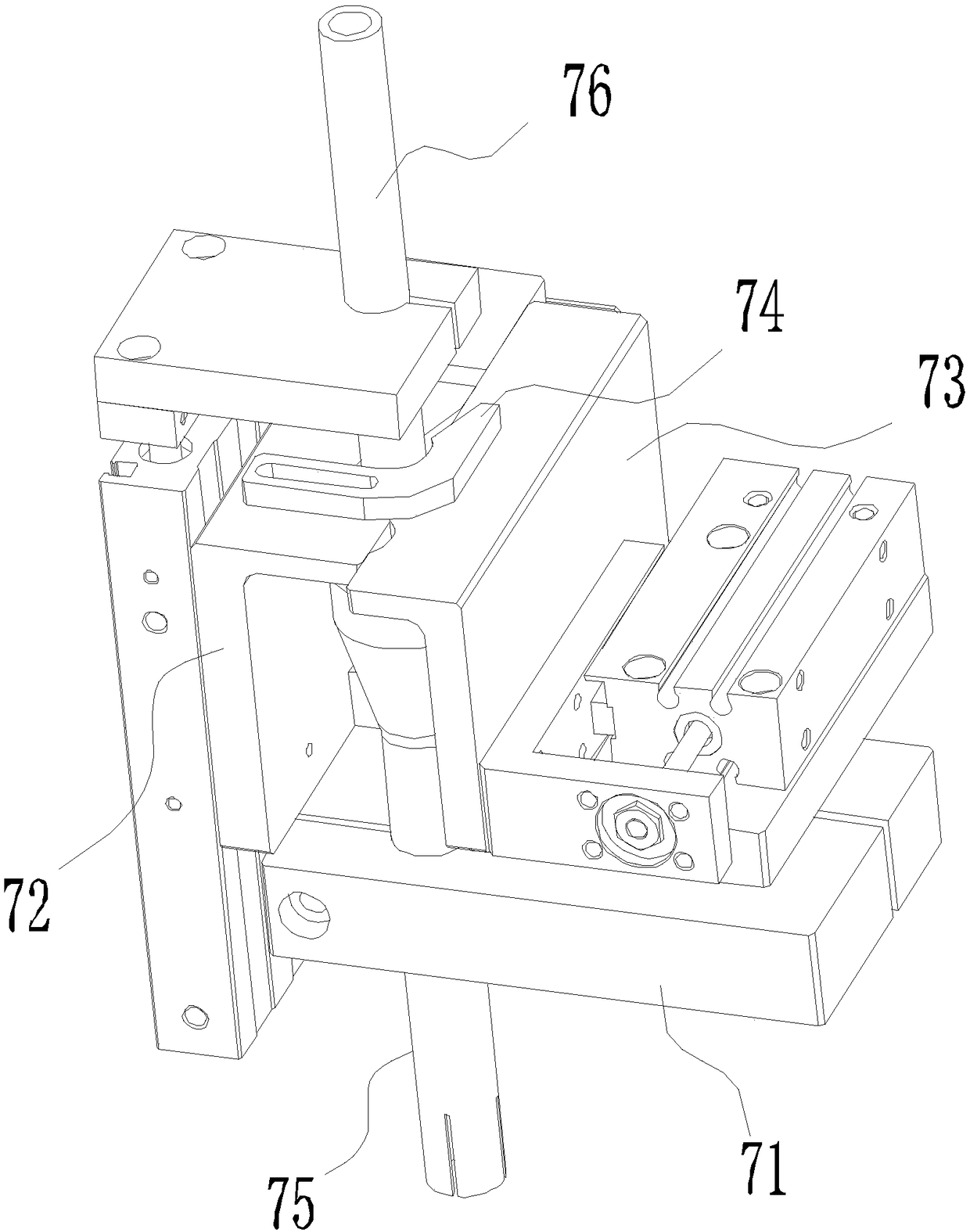

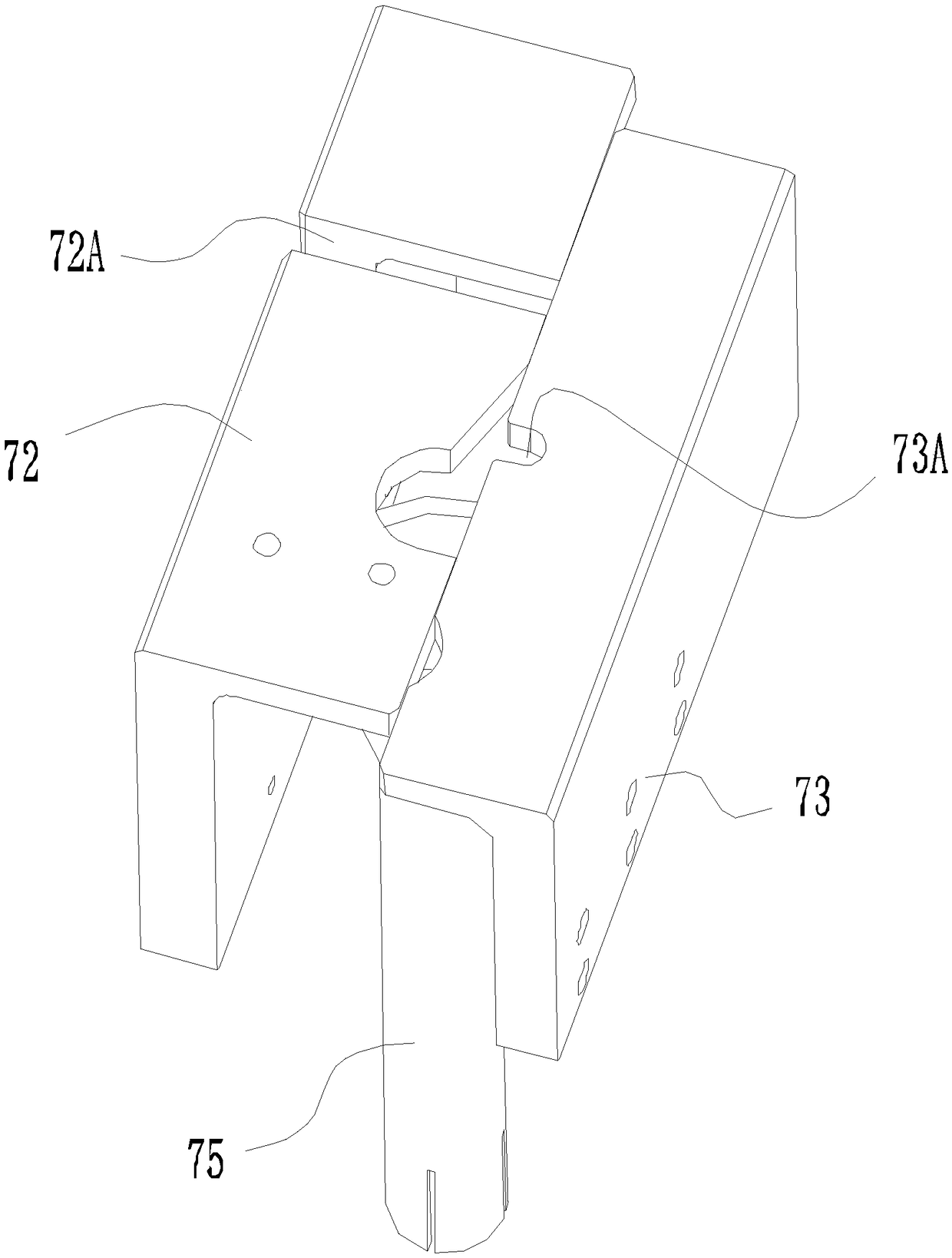

[0026] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

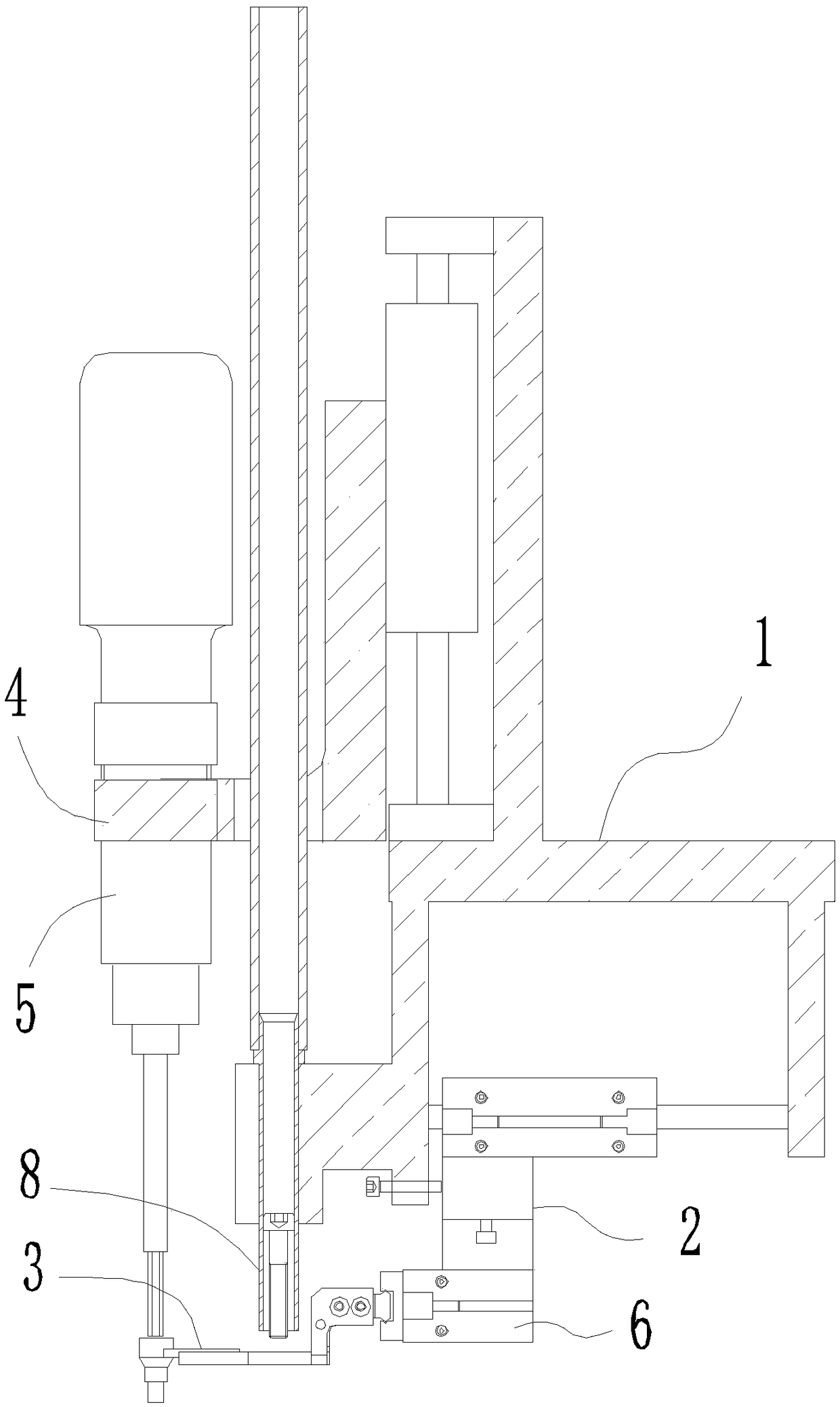

[0027] Such as Figure 1 to Figure 4 As shown, this embodiment provides a fully automatic screwing machine, including a nailing mechanism, the nailing mechanism is installed on the mechanical arm, the nailing mechanism includes a machine base 1, and the nailing station is provided on the machine base 1 and nailing stations.

[0028] The lower end of the machine base 1 is provided with a push nail slider 2, which reciprocates between the nailing station and the nailing station; the machine base 1 is provided with a first push cylinder, the first push cylinder is arranged horizontally, and the second push cylinder is arranged horizontally. A pushing cylinder is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com