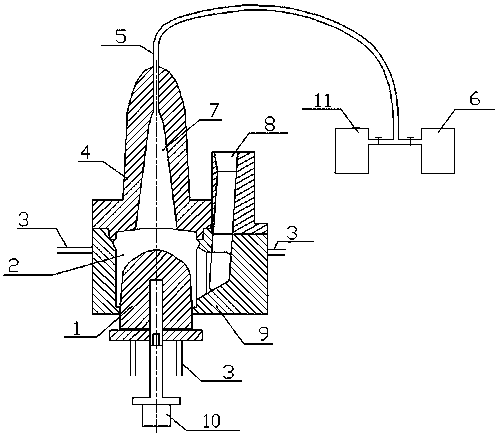

Preparation mold for piston for high-power engine and piston preparation method

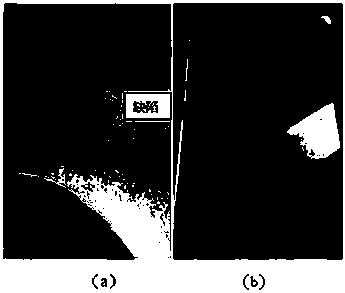

An engine and high-power technology, used in manufacturing tools, heat treatment equipment, casting and molding equipment, etc., can solve problems such as poor overall performance consistency, and achieve the effect of improving piston performance, eliminating pore defects, and strengthening high-temperature fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

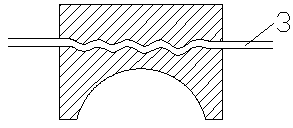

Method used

Image

Examples

Embodiment 1

[0030] The chemical composition of the eutectic Al-Si alloy is by weight percentage:

[0031] Si: 12.5%; Cu: 3%; Ni: 2%; Mg: 1.0%; Mn≤0.5%; Fe: ≤0.3%; Zr: ≤0.3%; Ti: ≤0.3%; V≤0.2 The rest is aluminum; the chemical composition of the ring aluminizing solution used in the piston preparation process includes aluminum, silicon, and magnesium, and its chemical composition is respectively by weight percentage: Si: 7%, Mg: 0.3%; the rest is aluminum.

[0032] A method for preparing a piston for a high-power engine, comprising the following steps:

[0033] Step 1: Preliminary preparation

[0034] a. Preparation of aluminum alloy melt for piston and ring aluminizing solution: clean the ingot surface of aluminum alloy for piston and aluminizing solution respectively, and melt it in a graphite crucible resistance furnace at 300°C for 4 hours after heat preservation. And adjust the composition of the melt, as well as the process of modification, refining and refinement.

[0035] b. Sal...

Embodiment 2

[0042] The chemical composition of the eutectic Al-Si alloy is by weight percentage:

[0043] Si: 11%; Cu: 3.8%; Ni: 2.5%; Mg: 0.7%; Mn≤0.5%; Fe: ≤0.3%; Zr: ≤0.3%; Ti: ≤0.3%; V≤0.2 The rest is aluminum; the chemical composition of the ring aluminizing solution used in the piston preparation process includes aluminum, silicon, and magnesium, and its chemical composition by weight percentage is: Si: 8%, Mg: 0.5%; the rest is aluminum.

[0044] A method for preparing a piston for a high-power engine, comprising the following steps:

[0045] Step 1: Preliminary preparation

[0046] a. Preparation of aluminum alloy melt for piston and ring aluminizing solution: clean the ingot surface of aluminum alloy for piston and aluminizing solution respectively, and melt it in a graphite crucible resistance furnace at 300°C for 4 hours after heat preservation. And adjust the composition of the melt, as well as the process of modification, refining and refinement.

[0047] b. Salt core heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com