Conveying device, system and method used for press line pressing machine room or multi-station pressing machine

A handling device and multi-station technology, which is applied in the field of handling devices for plate-shaped parts between the upper and lower dies of high-speed automatic stamping line presses, and can solve the problems of high total power installed by a single arm, complex structure of driving devices, and high energy consumption. , to achieve the effect of improving performance utilization efficiency, simple overall structure, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

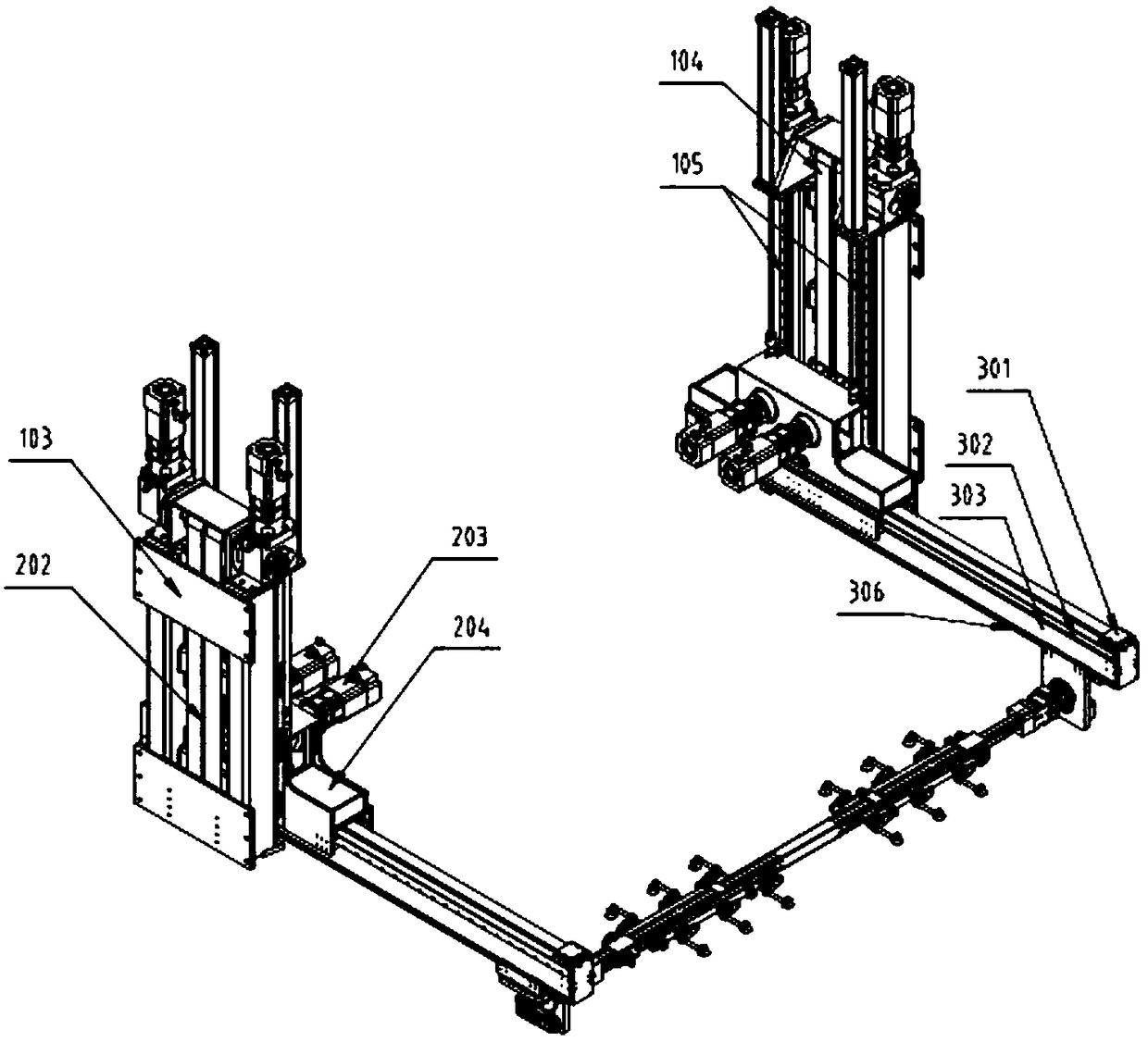

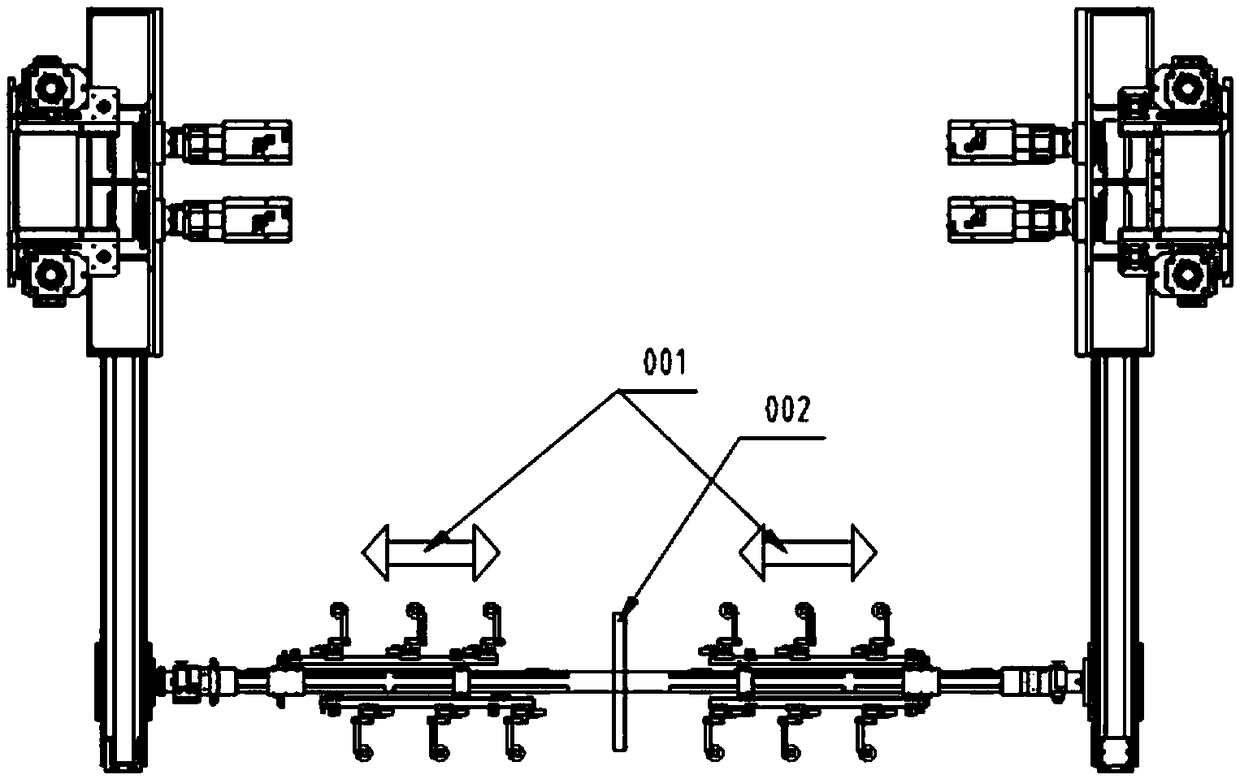

[0042] figure 1 Shown is a schematic front view of the structure of the present invention.

[0043] figure 2 Shown is the structural representation of the present invention.

[0044] figure 1 , figure 2 with image 3 In the illustrated embodiment, the plate-shaped part is a sheet metal blank or a processed / preliminarily formed blank.

[0045] The present invention is an extremely important part of the automatic stamping line, which is located at the front and rear positions of the metal forming press. The plate-shaped parts are disassembled by the destacking device, and the posture adjustment of the plate-shaped parts is completed by the centering device after passing through the cleaning machine / oiler. The invention is used to transfer the centered plate-shaped parts from the centering table to the mold area of the forming press, the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com