Screening device for gingkoes

A screening device and technology for ginkgo, applied in solid separation, classification, chemical instruments and methods, etc., can solve the problems of large damage and loss of nuts, incomplete separation of shells and kernels, and difficulty in shelling of ginkgo, so as to improve the screening accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

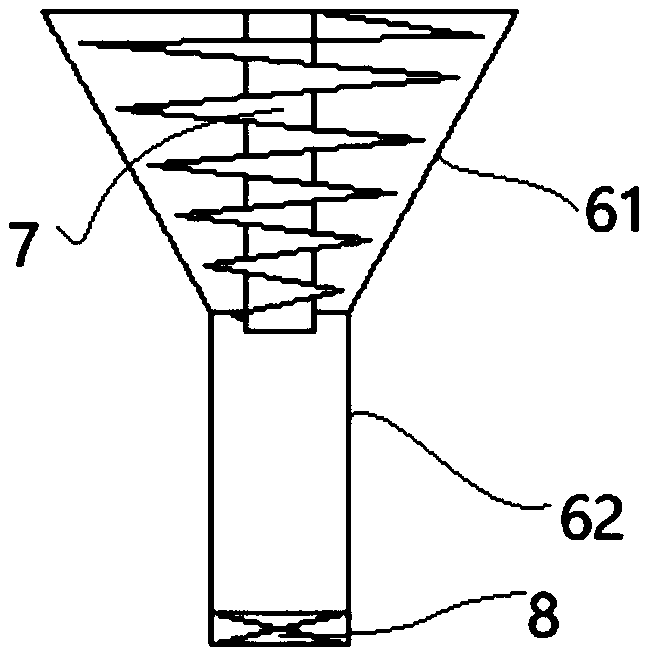

[0026] Such as figure 1 It is a specific embodiment of the ginkgo screening device disclosed in the present invention. The ginkgo screening device includes a frame body 1 and a transmission device arranged on the frame body 1. The transmission device includes a frame body fixed on the frame body 1. The connection end and the free end opposite to the connection end, the transmission device includes a screw shaft 2 and an optical shaft 3 arranged in parallel to each other, the screw shaft 2 is rotatably connected to the frame body 1, the The optical axis 3 is fixedly connected to the frame body 1; as figure 2 As shown, the optical axis 3 is provided with a first groove 31 along its radial direction, and the first groove 31 is arranged opposite to the screw shaft 2, and also includes a driving device for driving the screw shaft 2 to rotate (Fig. Not shown), the drive device drives the screw shaft 2 to rotate, so that the ginkgo particles on the transfer device are transferred f...

Embodiment 2

[0039] Figure 4 It is another embodiment of the ginkgo screening device of the present invention. This embodiment is basically the same as Embodiment 1, the difference is that the ginkgo screening device of Embodiment 1 is provided with a layer of conveying device. Setting, in the upper and lower layers of the transmission device, the gap between the spiral shaft 2 and the optical axis 3 is set up and down oppositely, and the gap between the upper and lower layers of the spiral shaft 2 and the optical axis 3 is the same, and the upper and lower The sizes of the first grooves 31 on the optical axis 3 of the two layers are the same.

[0040] When installing a layer of conveying device, if there are many ginkgo fruits in the gap between the spiral axis 2 and the optical axis 3, and they are stacked on each other, it is difficult to completely screen out the ginkgo fruits with smaller particles through one layer of conveying device. The ginkgo fruit at the end of the upper conv...

Embodiment 3

[0043] This embodiment is basically the same as embodiment 1, the difference is: the ginkgo screening device of embodiment 1 is provided with a layer of conveying device, in this embodiment, as Figure 5 As shown, the transmission device has two layers. In the transmission device of the upper and lower layers, the gap between the spiral shaft 2 and the optical axis 3 is arranged opposite to each other up and down, and the spiral shaft 2 of the upper and lower layers is connected to the optical axis 3. The gap size of the optical axis 3 is the same, the size of the first groove 31 on the optical axis 3 of the upper layer is larger than the size of the first groove 31 on the optical axis 3 of the lower layer, and the transmission length of the upper layer transmission device is greater than that of the lower layer transmission device. length.

[0044] In this embodiment, the receiving device includes three sliding receiving bins 4 that can slide along the conveying direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com