Reeling-type automatic cleaning floor mopping machine

An automatic cleaning and mopping machine technology, which is applied to manual floor scrubbing machines, carpet cleaning, floor cleaning, etc. It can solve the problems of poor stirring effect, long cleaning pool, and excessive water consumption, and achieve good dehydration effect and wide range. Wide working width and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

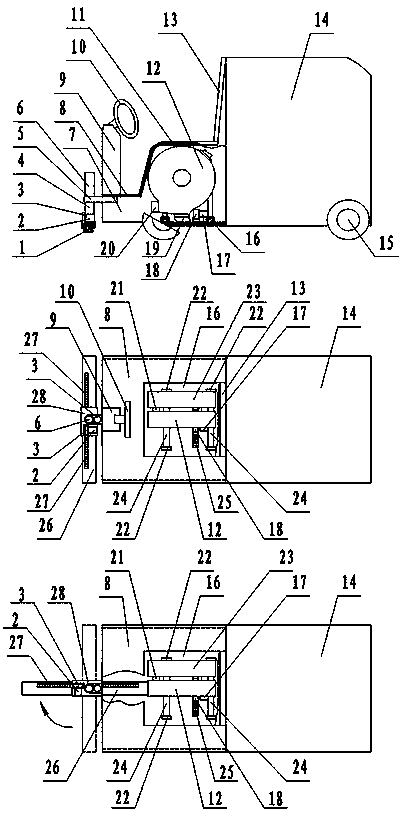

[0020] figure 1In the middle is the overall structure diagram of the reel type automatic cleaning and mopping machine. figure 1 The upper picture in the middle is the front view, the second row is the top view, and the lower picture is the situation when the mop turns to dock with the agitating shell. A mop is installed horizontally in front of the car body. Car body middle part is equipped with seat 11, and seat 11 front lower side is fixedly equipped with pedal 8. The lower side of the pedal 8 is fixedly equipped with a tube base frame 5, and the tube column 4 is installed at the front end of the tube base frame 5. A bracket shell 6 is installed on the pipe string 4 . The lower part of the pipe column is connected with the tank shell 28, and the translation motor 2 and the gear 3 are installed on the tank shell 28. The plate frame 26 on the mopping handkerchief is installed in the groove shell 28. A rack 27 is installed on the plate frame 26 . The handkerchief strip 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com