Spiral dust-gas separation device and gas purification device

A gas purification device, dust and gas separation technology, applied in the direction of suction filter, etc., can solve the problems of poor separation effect, many parts, complex structure, etc., achieve the effect of easy replacement, simple equipment, and avoid air flow disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

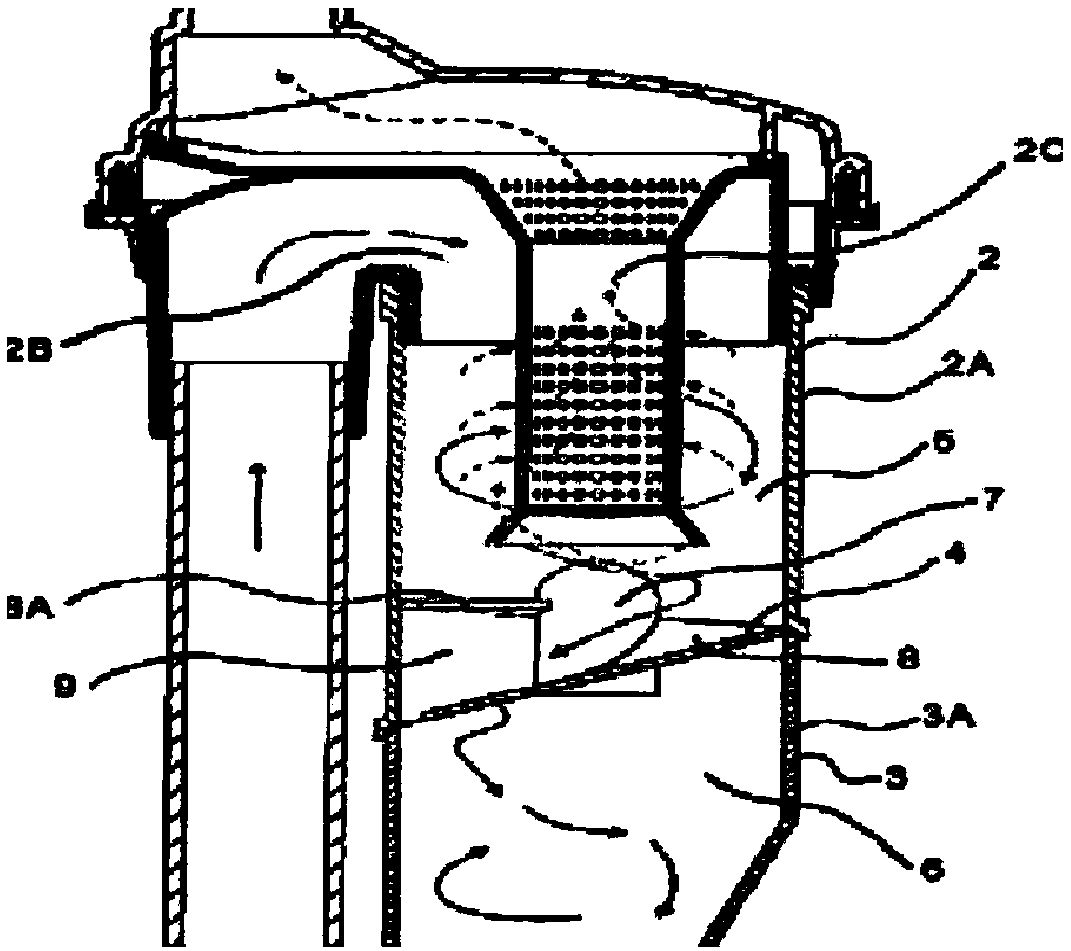

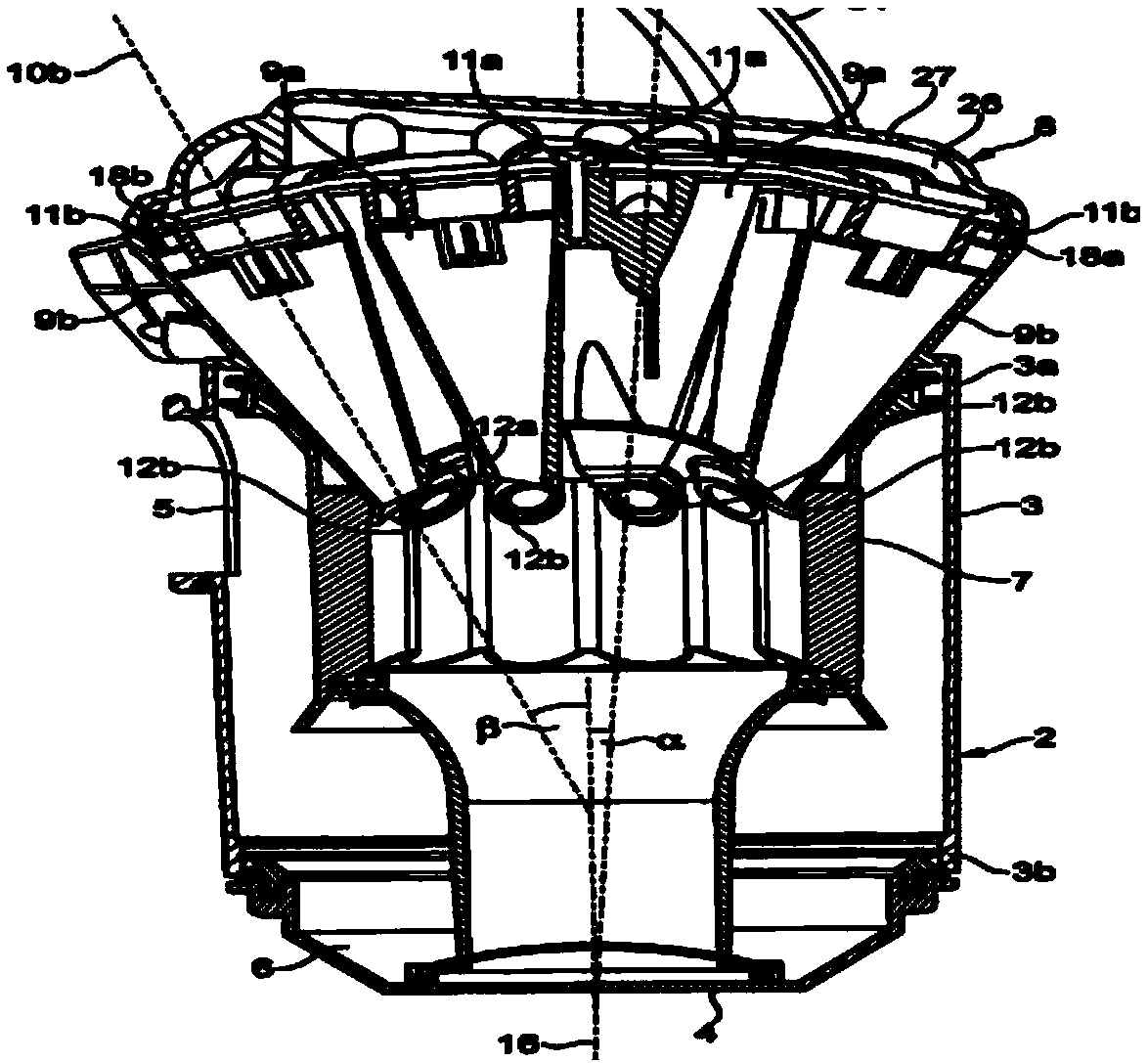

[0044] Such as Figure 3 to Figure 6 As shown, a spiral dust gas separation device provided in this embodiment includes: a cup body 1, a cup body air inlet 11 and a separator 2 are provided on the side wall, and are detachably embedded in the cup body 1.

[0045] Wherein the separator 2 is provided with: an upper guide vane 231 and a lower air deflector 232 parallel to each other and spiral downward. On the air inlet 25, and in a tangential positional relationship with the dust gas inlet direction;

[0046] In the inner pipe 21, a top cover is formed on the edge of the upper end inwardly to prevent dust from spreading from the middle of the inner pipe 21 to the outside, and the inner edges of the upper guide vane 231 and the lower guide vane 232 are connected to the inner On the tube 21, the upper end of the inner tube 21 is provided with a housing groove 24 for setting the filter 3, and the outer wall of the housing tank 24 is provided with a positioning groove extending awa...

Embodiment 2

[0055] This embodiment provides a gas purification device, specifically a vacuum cleaner, comprising:

[0056] The spiral dust gas separation device described in the above-mentioned embodiment 1 also has its own technical advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com