A kind of zero-added walnut milk and preparation method thereof

A walnut milk, zero additive technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of increased cost, inability to retain walnut flavor, and side effects on the body, and achieve stable emulsification state, flavor retention, and high nutritional content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

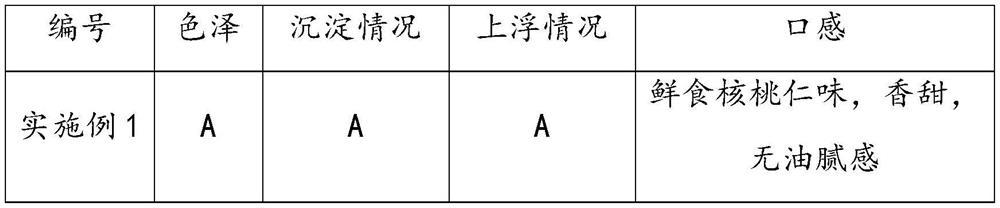

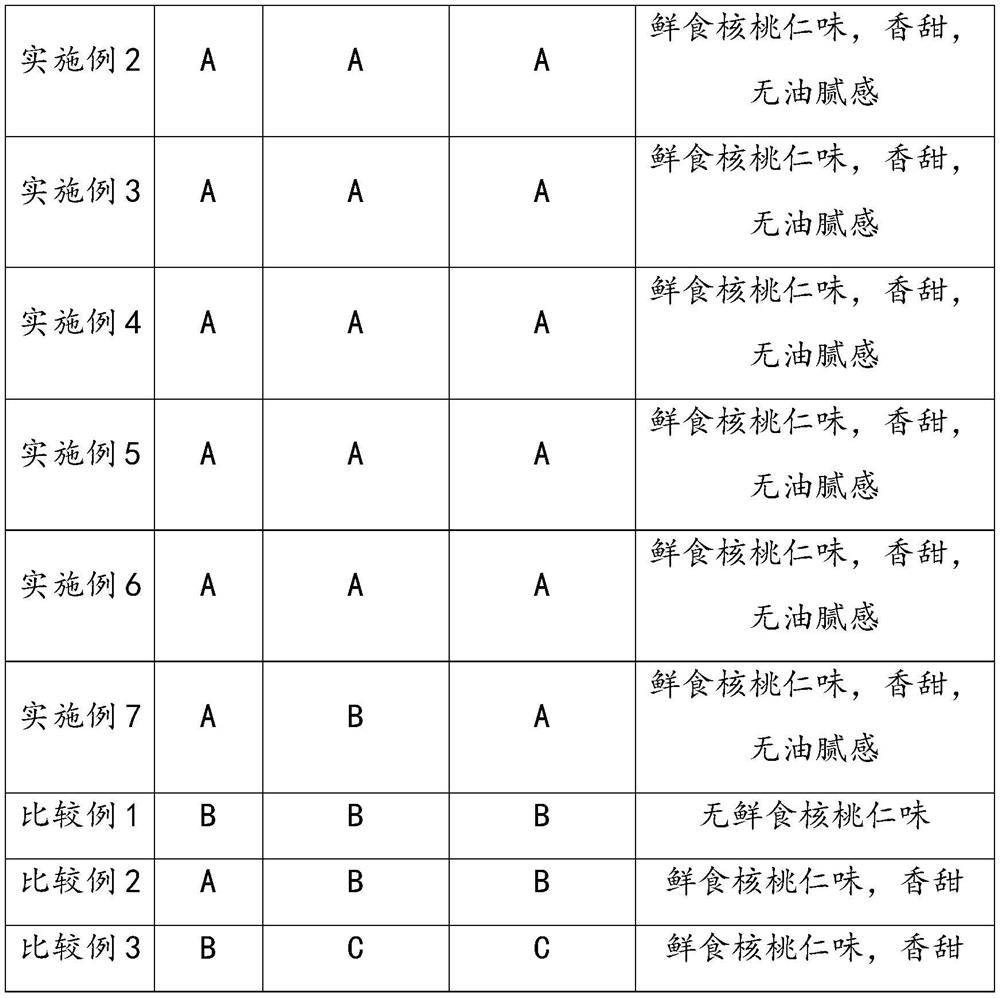

Examples

preparation example Construction

[0036] The invention provides a preparation method of zero-added walnut milk, comprising the following steps:

[0037] The walnut kernels and water are mixed and refined in a mass ratio of 1:(2-10) and homogenized in three stages to obtain the zero-added walnut milk;

[0038] Wherein, the walnut kernels are pretreated by peeling the walnut kernels, rehydrating in 0-5°C water, and then rewarming in 40-50°C water.

[0039] In the preparation method of zero-added walnut milk according to the present invention, the walnut kernels are peeled, used and rehydrated, which can protect the walnut kernels from being oxidized, and the rehydrated walnut kernels can achieve the taste of fresh walnut kernels, and the taste It is smooth, sweet, and non-greasy; in addition, a specific proportion of walnut kernels and water are used for mixing and refining, and a specific three-level homogenization can be used to ensure that the walnut kernel itself can be used without any additives such as emu...

Embodiment 1

[0059] The preparation method of the walnut milk described in the present embodiment, the steps are as follows:

[0060] (1) Select walnut kernels: choose walnut kernels with full grains, no moths, and no mildew;

[0061] (2) Peeling of walnut kernels: Soak walnut kernels in water at 85°C for 10 minutes. After soaking, rinse and peel them with 0.5-0.6MPa high-pressure water; Wash the walnut kernels with pure water to remove the dirt on the surface;

[0062] (3) Rehydration: put the walnut kernels obtained in step (2) into pure water at 0-5°C for rehydration operation, all the walnut kernels are soaked in water, and after soaking for 4 hours, carry out the rehydration operation through pure water at 45-50°C reheating treatment;

[0063] (4) Refining: Mix the walnut kernels and water obtained in step (3) according to the mass ratio of 1:2.5, the water temperature is 80-85°C, and use a colloid mill to refine until the particle size in the slurry is ≥ 80 mesh and the number acco...

Embodiment 2

[0068] The preparation method of the walnut milk described in the present embodiment, the steps are as follows:

[0069] (1) Select walnut kernels: choose walnut kernels with full grains, no moths, and no mildew;

[0070] (2) Peeling of walnut kernels: Soak walnut kernels in water at 85°C for 10 minutes. After soaking, rinse and peel them with 0.5-0.6MPa high-pressure water; Wash the walnut kernels with pure water to remove the dirt on the surface;

[0071] (3) Rehydration: put the walnut kernels obtained in step (2) into pure water at 0-5°C for rehydration operation, all the walnut kernels are soaked in water, and after soaking for 4 hours, carry out the rehydration operation through pure water at 45-50°C reheating treatment;

[0072] (4) Refining: Mix the walnut kernels and water obtained in step (3) according to the mass ratio of 1:2, the water temperature is 80-85°C, and use a colloid mill to refine until the particle size in the slurry is ≥ 80 mesh. %above;

[0073] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com