A dust-proof device

A technology for dust-proof devices and dust-proof parts, which is applied in the directions of instruments, computing, digital processing power distribution, etc., can solve the problems of poor electromagnetic shielding performance, complicated maintenance, disassembly, frequent replacement of dust-proof nets, etc., to achieve convenient opening and closing, guaranteeing Heat dissipation requirements and the effect of ensuring electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

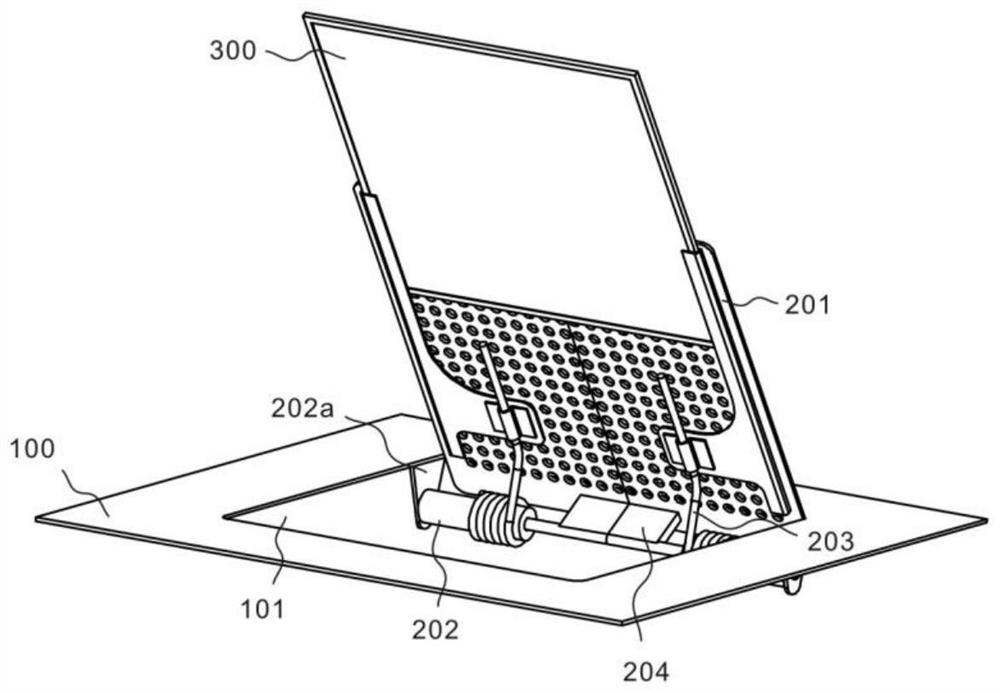

[0037] Such as figure 1As indicated in , since the chassis of the industrial computer needs to dissipate heat, the heat dissipation port will be set to dissipate heat from the chassis, and the dust-proof measures for the heat dissipation port will directly affect the service status and life of the industrial computer, so dust-proof parts are usually installed on the heat dissipation port 300 is used for dust prevention. As time goes by, the dust-proof component 300 will need to be replaced or cleaned due to the accumulation of dust. Therefore, in order to facilitate the disassembly, replacement and maintenance of the heat-dissipating and dust-proof component 300 on the chassis of the industrial computer, this embodiment Among them, the dustproof device is used on the industrial control computer case, and the device includes a case panel 100 , a turning assembly 200 and a dustproof part 300 . Specifically, the chassis panel 100 is provided with a heat dissipation hole 101 of th...

Embodiment 2

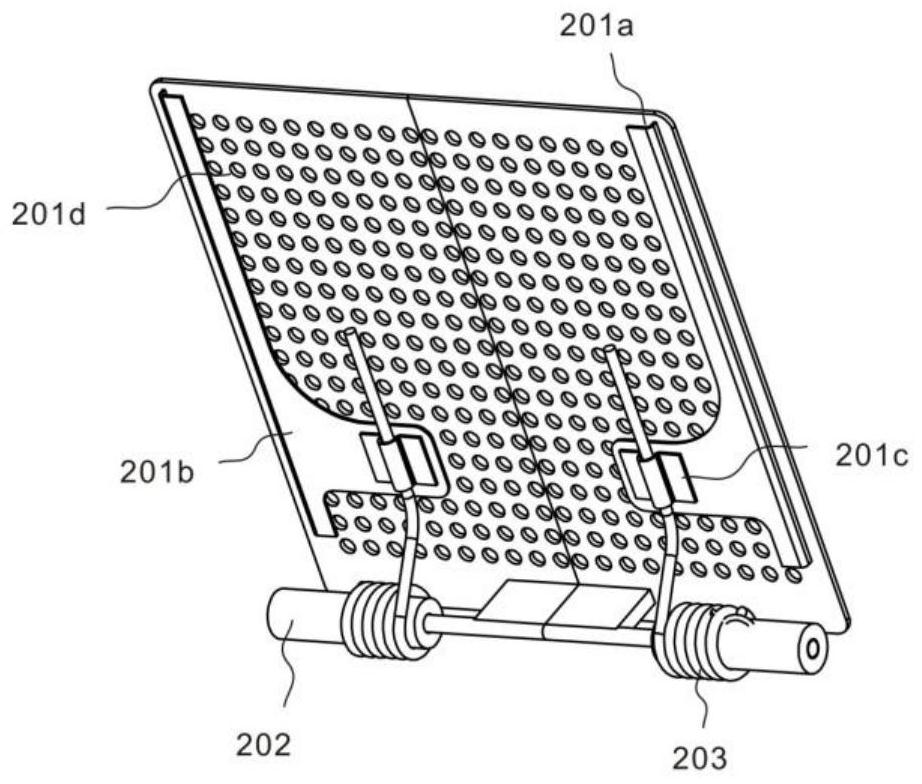

[0039] Such as figure 2 Indicated in, and refer to figure 1 As shown in the figure, in order to realize the automatic reset of the turning assembly 200 and the closing under force in the initial state, the turning assembly 200 in this embodiment further includes a turning plate 201 , a turning shaft 202 and a turning spring 203 . Specifically, the chassis panel 100 is provided with a heat dissipation hole 101 of the chassis for heat dissipation of the chassis; the flip assembly 200 is arranged in the heat dissipation hole 101 and is hinged between one end and the chassis panel 100, and the heat dissipation hole 101 is turned over by the flip assembly 200. The opening of the cabinet is sealed or opened; and the dustproof part 300 is arranged in the flip assembly 200; it should be noted that it is not difficult to find that the cabinet panel 100 can be arranged on any surface of the cabinet as a closing plate on any face of the cabinet , the general chassis is a regular cuboid...

Embodiment 3

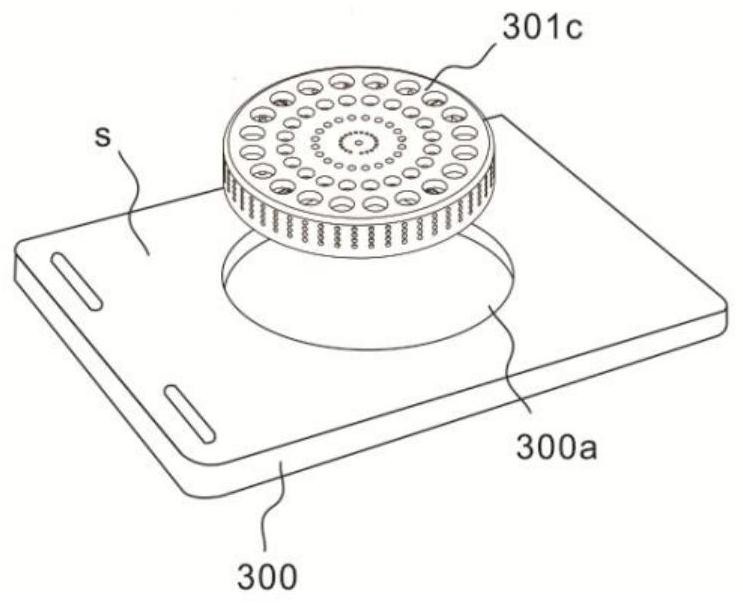

[0041] This embodiment provides a sensor assembly applied to the dust-proof component 300 in the above-mentioned embodiment. By installing a temperature sensor in the dust-proof component 300, the temperature of the chassis is monitored, and an alarm can be issued when the temperature is too high. pass image 3 The indicator light shown in the picture (not shown in the figure) or the existing loudspeaker is used to realize the alarm, which can promptly notify the staff to deal with it, prevent the case from burning out when the temperature is too high, and curb the potential safety hazard of fire. What needs to be explained here is that because the temperature sensor is set in the dust-proof member 300, a large amount of dust will accumulate and affect the performance of the sensor as time goes by. Therefore, in order to facilitate disassembly, replacement or maintenance of the sensor device, to maintain the performance of the temperature sensor , so that the monitoring is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com