Airtightness detector for pump of pressure vessel

A pressure vessel and testing machine technology, which can be used in liquid/vacuum measurement for liquid tightness, and by detecting the appearance of fluid at the leak point, etc., can solve the problems of low degree of automation, high labor consumption, and low detection efficiency, etc. Achieve the effect of improving the degree of automation and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

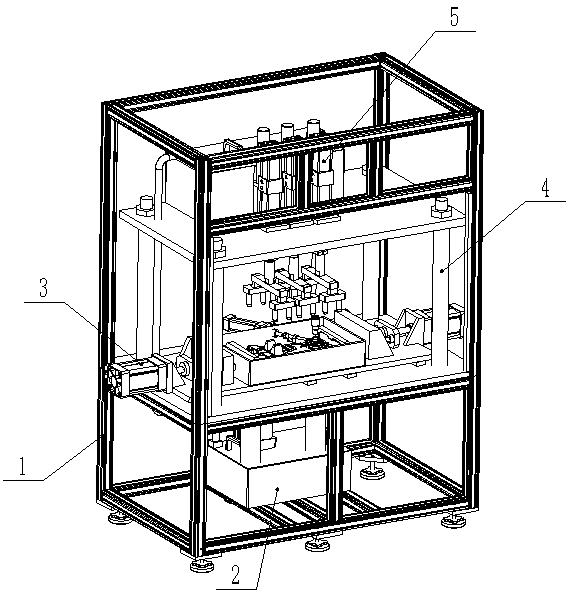

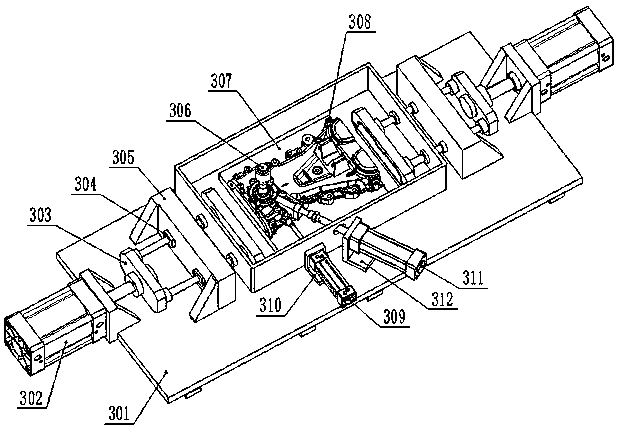

[0015] Example: such as figure 1 , figure 2 , image 3 , Figure 4 A pressure vessel pump body air tightness testing machine shown includes a main frame body 1, a water supply and drainage unit 2, a clamping and fixing unit 3, a mounting frame 4, and a pressing unit 5. The main frame body 1 is used as a whole The installation standard of the mechanism is that the installation frame 4 is fixed in the middle of the main frame body 1, the lower part of the water supply and drainage unit 2 is installed on the bottom side of the main frame body 1, the upper part is installed on the top side of the installation frame 4, and the clamping and fixing unit 3 is installed on the On the bottom plate of the mounting frame 4 , the pressing unit 5 is installed on the top plate of the mounting frame 4 .

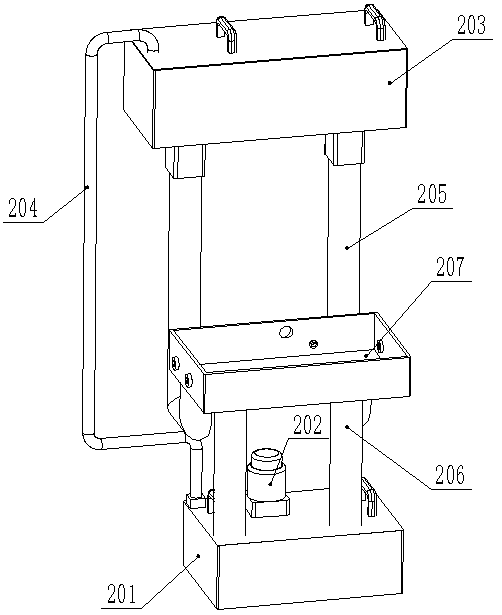

[0016] The water supply and drainage unit 2 includes a lower water tank 201, a water pump 202, an upper water tank 203, a water inlet pipe 204, a water outlet pipe 205, a drain pipe 206,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com