Two-body-type fixed ball valve and manufacturing method thereof

A fixed ball valve and body type technology, applied in the direction of valve details, valve device, valve shell structure, etc., can solve the problems of DBB function deterioration, DBB function poorness, and the difficulty of ensuring the verticality of the valve assembly end face, etc., to reduce the coaxiality Deviation, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

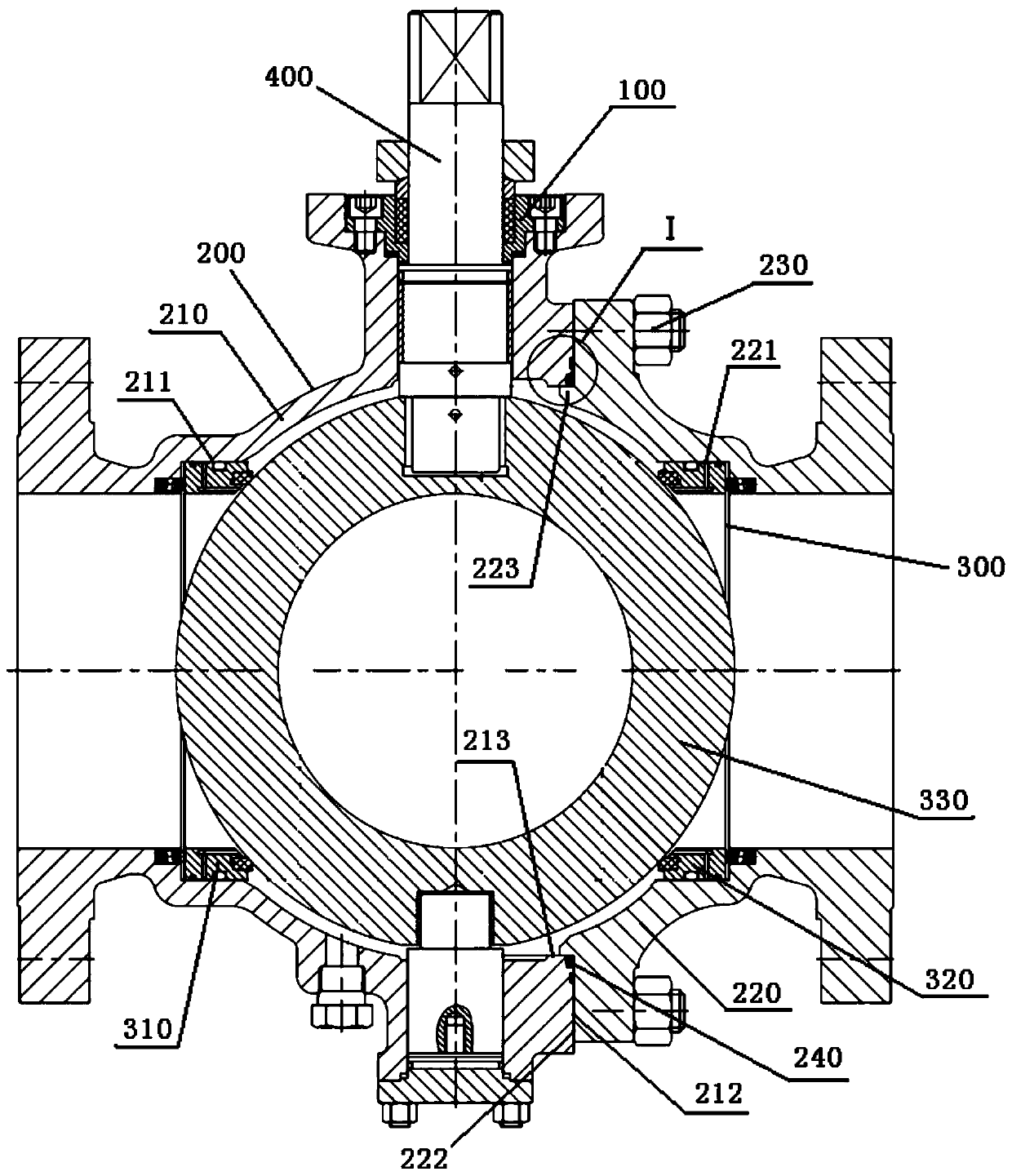

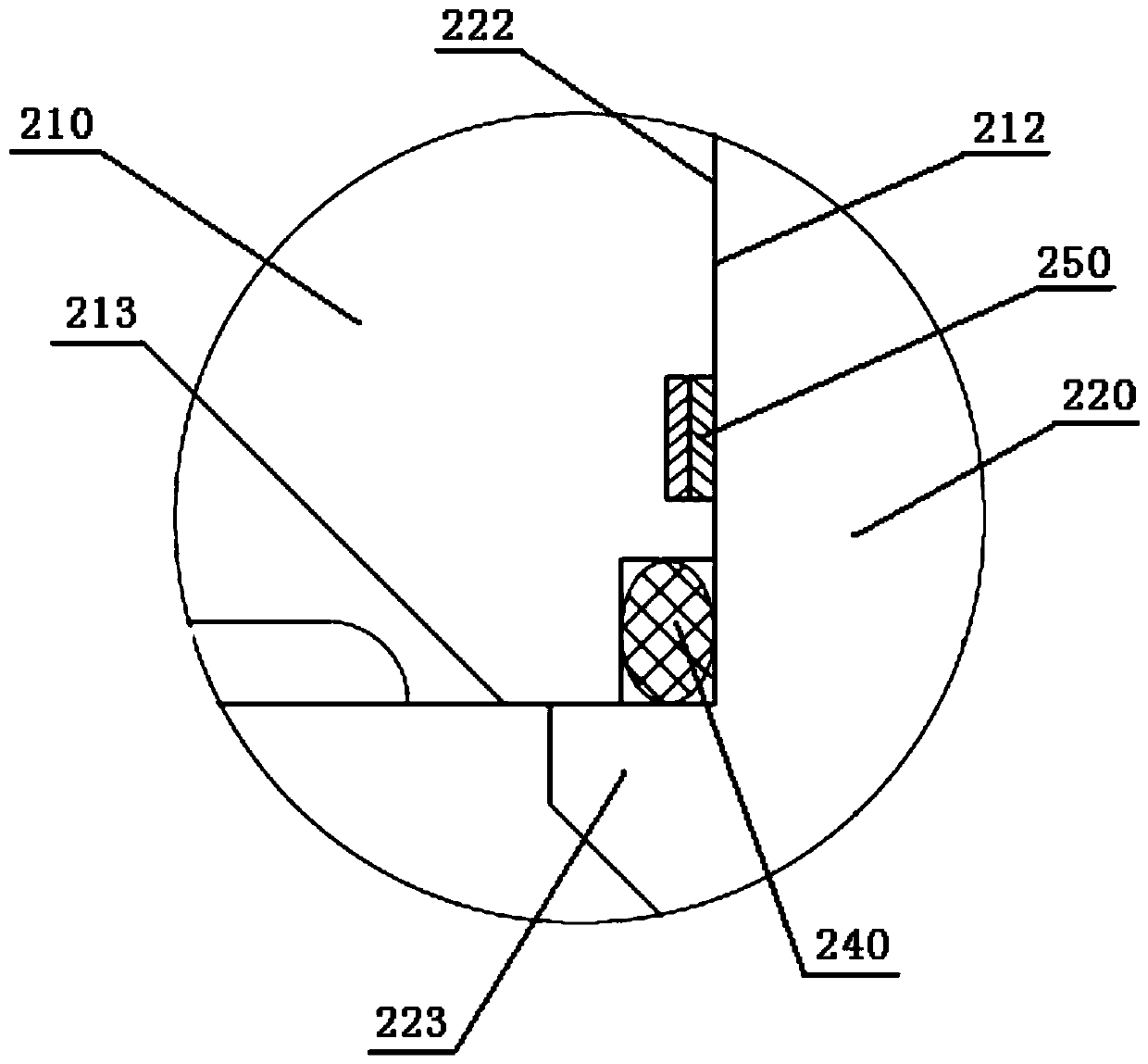

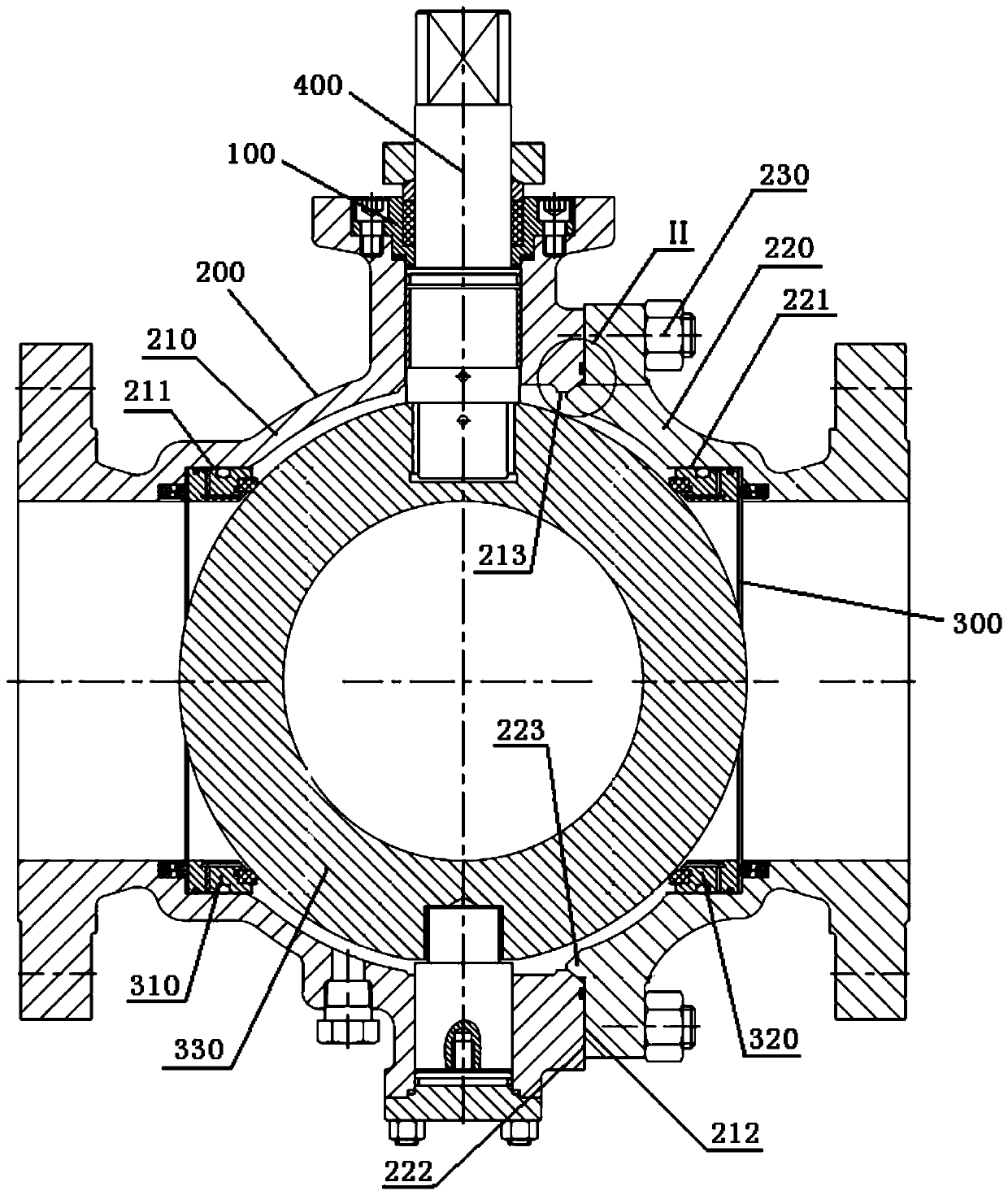

[0024] combine image 3 and Figure 4 As shown, the two-piece fixed ball valve includes a valve body 200, and the valve body 200 includes a left valve body 210 with a left valve seat hole 211 and a right valve body 220 with a right valve seat hole 221; the right valve body 220 The left end is provided with a ring-shaped first assembly end surface 222, and the first assembly end surface 222 is provided with a connecting ring 223 coaxial with the right valve seat hole 221, and the left valve body 210 is provided with the first assembly end surface 222. Corresponding to the second assembly end surface 212, the second assembly end surface 212 is provided with a connection hole 213 coaxial with the left valve seat hole 211; the inner wall surface at the right end of the connection hole 213 is a tapered guiding and positioning surface 214 , the outer wall surface of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com