Comprehensive test table for mass center and rotational inertia of large-tonnage product

A moment of inertia and comprehensive testing technology, which is applied in static/dynamic balance testing, machine/structural component testing, measuring devices, etc., can solve the problems of inconvenient testing, low measurement accuracy, labor-intensive manual operation, etc., to achieve The effect of improved safety factor, good test cycle and shortened measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

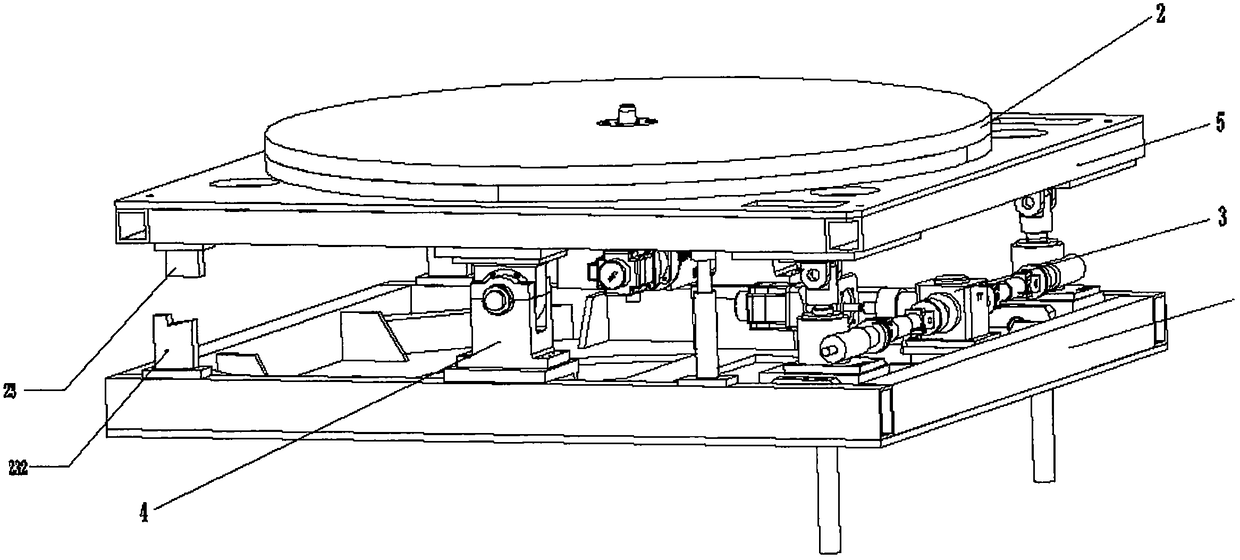

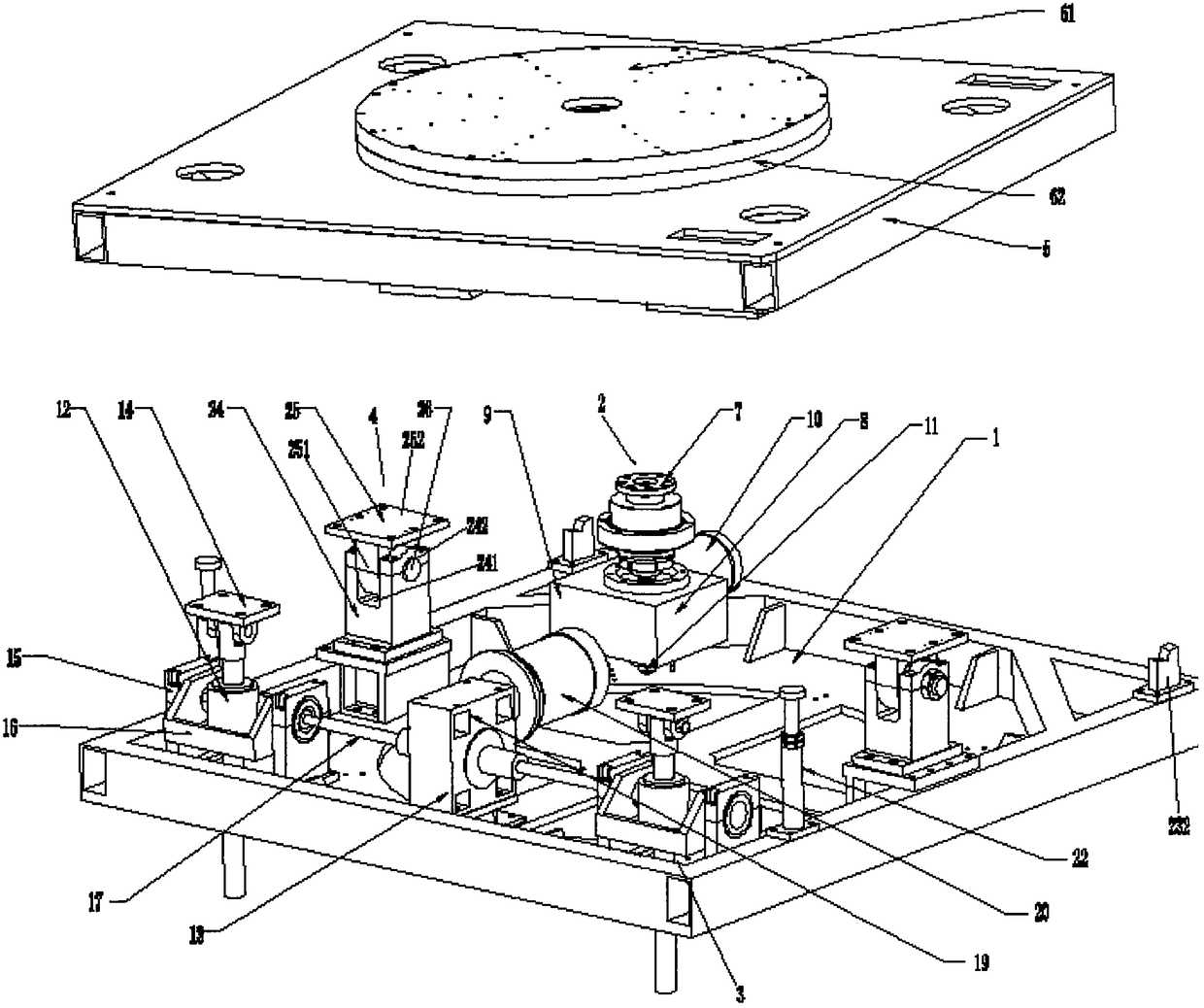

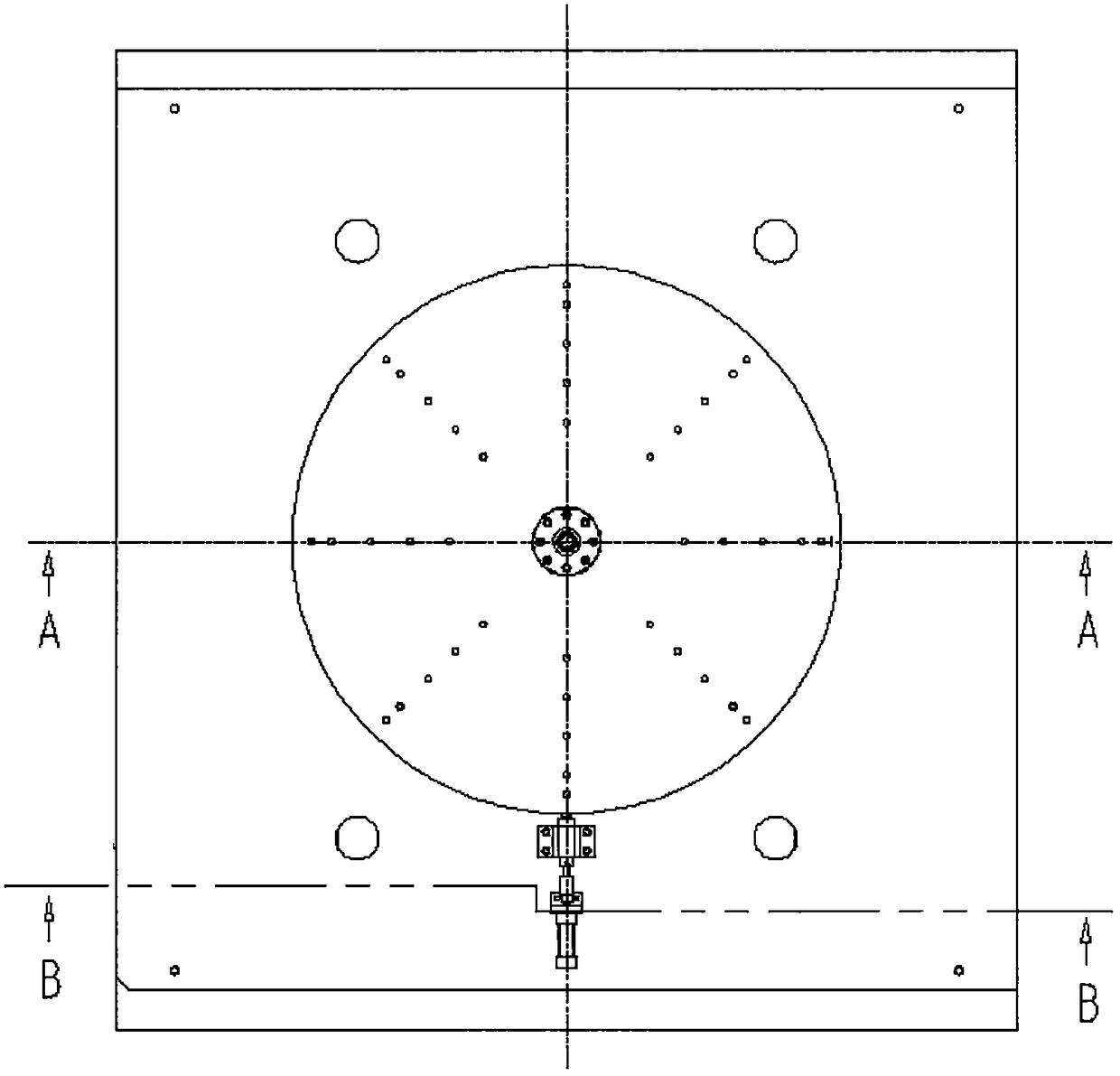

[0039] 1. During the horizontal measurement of the center of mass, the upper plate 5 is in a horizontal state for measurement. After the test is completed, press the up button to start the servo motor 220, which sequentially drives the planetary reducer, the T series spiral bevel gear commutator, and the two A worm gear screw lifter 120, the lifting screw mandrel 121 jacks up the upper platen 5 and rises, so that the upper platen 5 rises to the inclination angle of the test and stops rising, and each connecting part of the worm gear screw lifter 120 is self-locked and locked, and the inclination measurement is carried out;

[0040] After the test is completed, press the down button to start the servo motor 220, which in turn drives the planetary reducer, the T series spiral bevel gear reversing device 130, and the two worm gear screw lifters 120, and the lifting screw 121 descends to make the upper table 5 horizontal .

[0041] 2. During the moment of inertia test, the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com