Thermal recovery packing box with replaceable polish rod

A packing box and polished rod technology, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problems of long downtime, low productivity, long operation cycle, etc., and achieves improved productivity and reasonable structure. , the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0021] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, rear, top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the description.

[0022] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

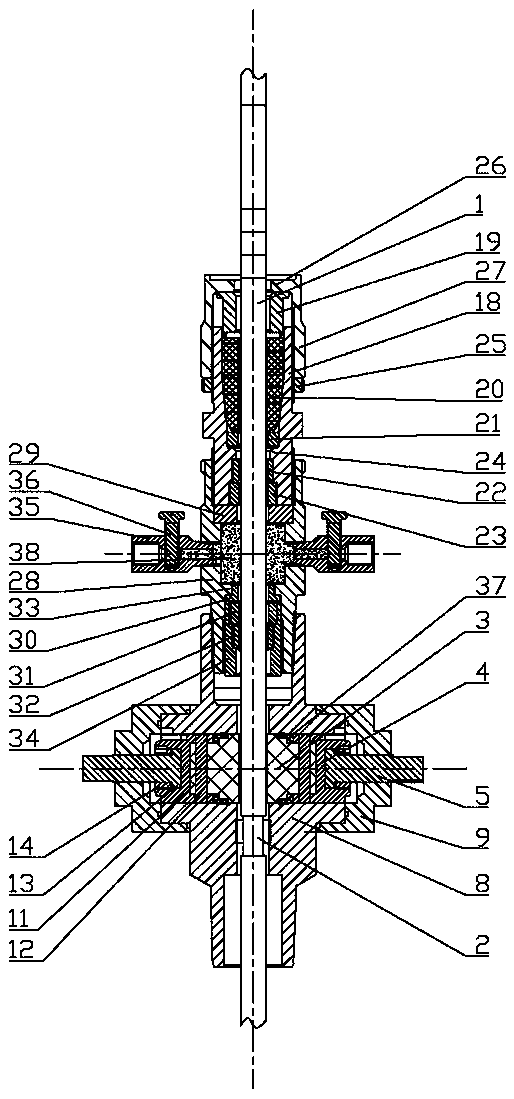

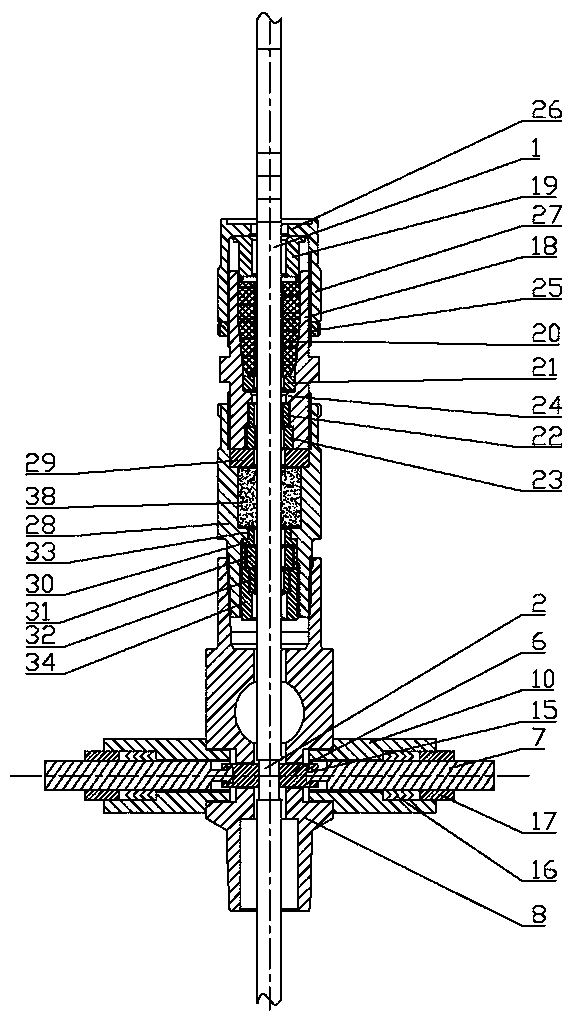

[0023] as attached figure 1 , 2 As shown, the replaceable polished rod hot mining packing box includes a polished rod holding sealing body, and the polished rod holding sealing body includes a holding sealing shell, a sealing assembly and a holding assembly, and the holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com