High-low temperature urea grease composition with flame resistance and preparation method of high-low temperature urea grease composition

A urea-based lubricating grease, high and low temperature technology, applied in the field of lubricating grease, can solve the problems of inability to balance high and low temperature performance, fire, fire, etc., achieve good extreme pressure and anti-wear performance, simple preparation method, good flame resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

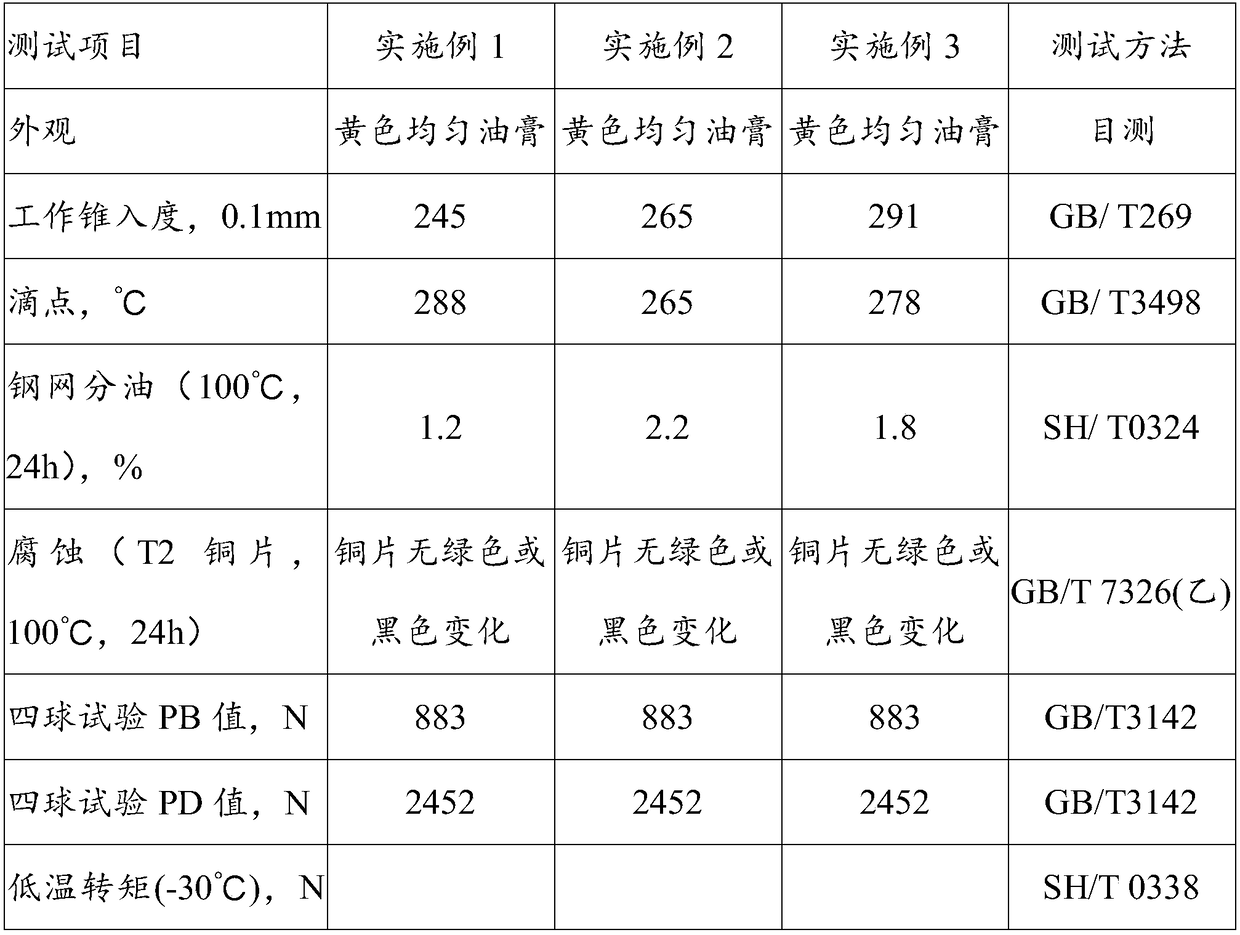

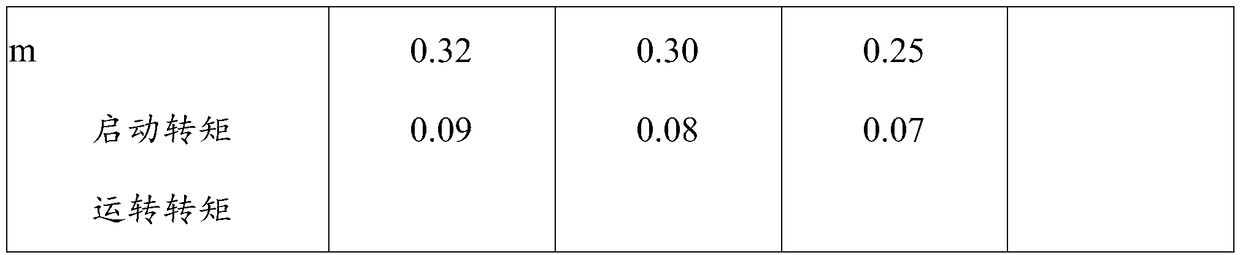

Embodiment 1

[0022] A flame-resistant high and low temperature urea-based grease composition, the composition of which is as follows:

[0023] Synthetic Base Oil: Pentaerythritol Ester, 83.0g

[0024] Polyurea thickener: diphenylmethane diisocyanate MDI (3.5g), octadecylamine (4.5g), aniline (1.0g)

[0025] Polyvinyl alcohol: 2.0g

[0026] Polyisobutylene glue: 2.0g

[0027] Zinc dialkyldithiophosphate: 2.0g

[0028] Micro-nano borate T361A: 2.0g

[0029] production method:

[0030] (1) Put 50% of the total weight of base oil into the first reaction kettle, heat to 50-60°C, then add all octadecylamine and aniline, stir and heat to 70-80°C.

[0031] (2) Put the remaining base oil into the second reaction kettle, raise the temperature to 50-60°C, then add MDI, stir and raise the temperature to 70-80°C.

[0032] (3) Add all the amine solution in the first reaction kettle to the second reaction kettle under the condition of non-stop stirring.

[0033] (4) Keep the temperature at 100-110...

Embodiment 2

[0040] A flame-resistant high and low temperature urea-based grease composition, the composition of which is as follows:

[0041] Synthetic base oil: trimethylolpropane ester (40.0g), pentaerythritol ester (38.0g)

[0042] Polyurea thickener: toluene diisocyanate TDI (4.0g), ethylenediamine (0.7g), octadecylamine (6.3g)

[0043] Polyvinyl alcohol: 3.0g

[0044] Polyisobutylene glue: 3.0g

[0045] Zinc dialkyldithiophosphate: 3.0g

[0046] Micro-nano borate T361A: 2.0g

[0047] production method:

[0048] (1) Put 50% of the total weight of base oil into the first reaction kettle, heat to 50-60°C, then add all octadecylamine and ethylenediamine, stir and heat to 70-80°C.

[0049] (2) Put the remaining base oil into the second reaction kettle, raise the temperature to 50-60°C, then add MDI, stir and raise the temperature to 70-80°C.

[0050] (3) Add all the amine solution in the first reaction kettle to the second reaction kettle under the condition of non-stop stirring.

...

Embodiment 3

[0058] A flame-resistant high and low temperature urea-based grease composition, the composition of which is as follows:

[0059] Synthetic Base Oil: Trimethylolpropane Ester, 79.0g

[0060] Polyurea thickener: diphenylmethane diisocyanate MDI (5.0g), aniline (1.4g), n-octylamine (3.2g)

[0061] Polyvinyl alcohol: 3.0g

[0062] Polyisobutylene glue: 3.4g

[0063] Zinc dialkyldithiophosphate: 3.0g

[0064] Micro-nano borate T361A: 2.0g

[0065] production method:

[0066] (1) Put 50% of the total weight of base oil into the first reaction kettle, heat to 50-60°C, then add all n-octylamine and aniline, stir and heat to 70-80°C.

[0067] (2) Put the remaining base oil into the second reaction kettle, raise the temperature to 50-60°C, then add MDI, stir and raise the temperature to 70-80°C.

[0068] (3) Add all the amine solution in the first reaction kettle to the second reaction kettle under the condition of non-stop stirring.

[0069] (4) Keep the temperature at 100-110°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com