Industrial sludge recycling method

A technology for industrial sludge and treatment methods, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. Secondary pollution and other issues to ensure continuous, safe and stable operation, avoid secondary pollution, and reduce disposal energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

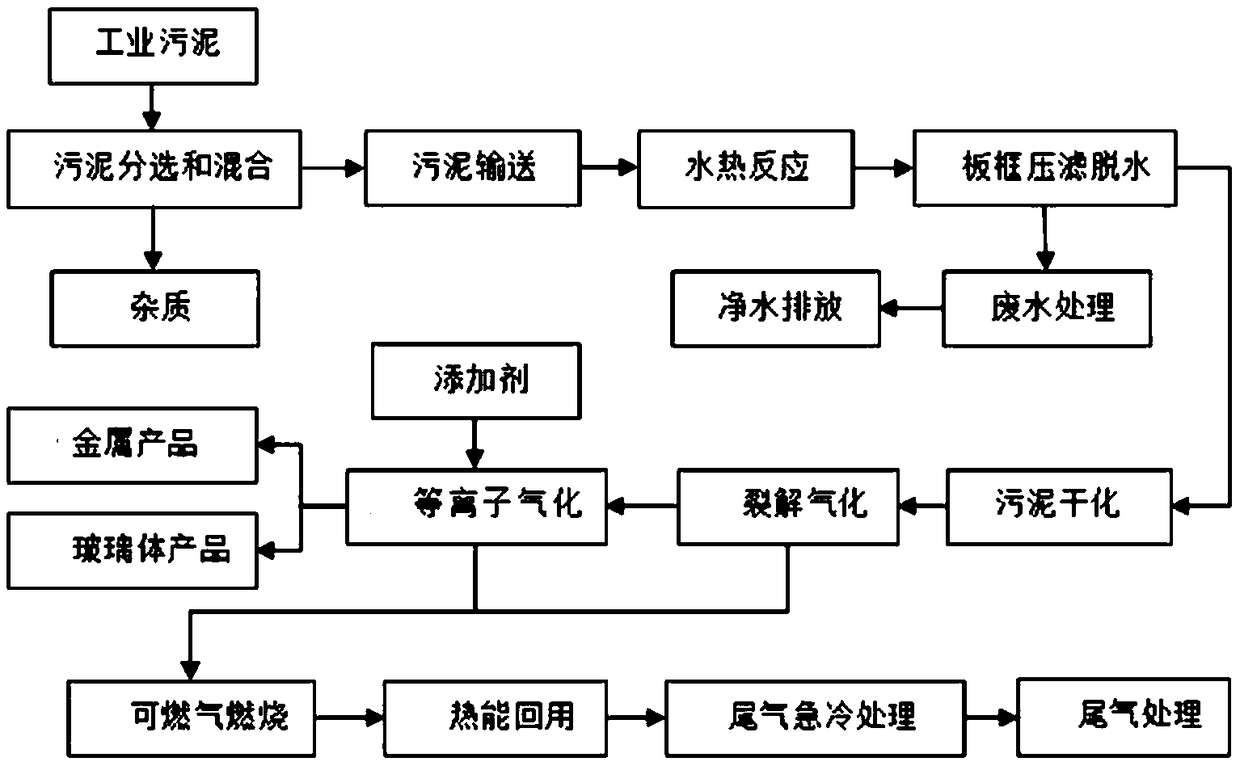

[0033] As a most basic embodiment of the present invention, a kind of industrial sludge resource treatment method is disclosed, such as figure 1 , including the following steps:

[0034] Sludge sorting and mixing step: The industrial sludge to be treated is sent to the sludge sorting machine according to the classification of physical and chemical sludge and biochemical sludge to remove impurities, such as packaging, stones, iron pieces, etc. To facilitate subsequent sludge transportation and improve the efficiency of hydrothermal reaction treatment, according to the source and type of industrial sludge, the physical and chemical sludge and biochemical sludge are fully mixed according to the mass ratio of 1: (1~5) during the sorting process;

[0035] Sludge conveying step: the industrial sludge after the sludge sorting and mixing step is sent to the hydrothermal reactor through the conveying pump. In addition to the conveying function, the sludge conveying device can also cont...

Embodiment approach

[0046] As a preferred embodiment of the method of the present invention, a method for recycling industrial sludge is disclosed, such as figure 1 , including the following steps:

[0047] Sludge sorting and mixing step: The industrial sludge to be treated is sent to the sludge sorting machine according to the classification of physical and chemical sludge and biochemical sludge to remove impurities, such as packaging, stones, iron pieces, etc. To facilitate subsequent sludge transportation and improve the efficiency of hydrothermal reaction treatment, according to the source and type of industrial sludge, the physical and chemical sludge and biochemical sludge are fully mixed according to the mass ratio of 1: (1~5) during the sorting process;

[0048] Sludge conveying step: the industrial sludge after the sludge sorting and mixing step is sent to the hydrothermal reactor through the conveying pump. In addition to the conveying function, the sludge conveying device can also cont...

Embodiment 3

[0057] As a preferred embodiment of the present invention, a method for recycling industrial sludge is disclosed, such as figure 1 , including the following steps:

[0058] 1. Sludge sorting and mixing steps: Send the industrial sludge to be treated to the sludge sorting machine for sorting to remove impurities, such as packaging, stones, iron pieces and other substances. At the same time, in order to facilitate subsequent sludge transportation and improve the efficiency of hydrothermal reaction treatment, according to the different sources and types of industrial sludge, physical and chemical sludge and biochemical sludge are fully separated according to the mass ratio of 1: (1~5) during the sorting process. mix.

[0059] 2. Sludge conveying step: After sorting and mixing, the sludge is sent to the hydrothermal reactor through the conveying pump. In addition to the conveying function, the sludge conveying device can also control the conveying amount according to requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com