Cutting construction method of anchor cable cutting machine

A cable cutting machine and construction method technology, applied in the field of foundation pit pile anchor support equipment, can solve the problems of slow cutting anchor cable speed, low work efficiency, inconvenient movement of the cutting device, etc., and achieve the effect of convenient movement and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

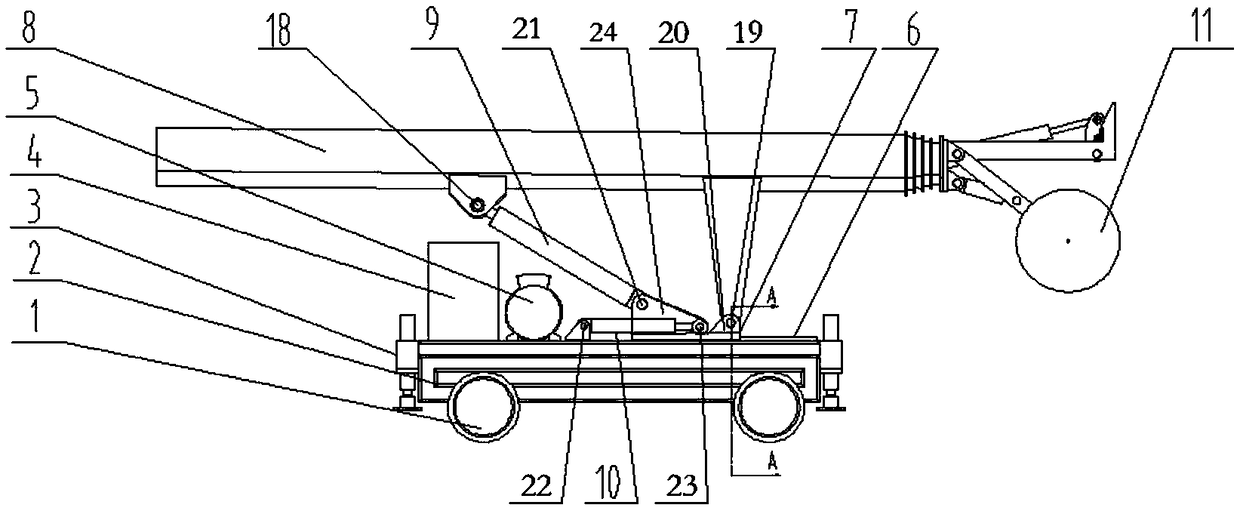

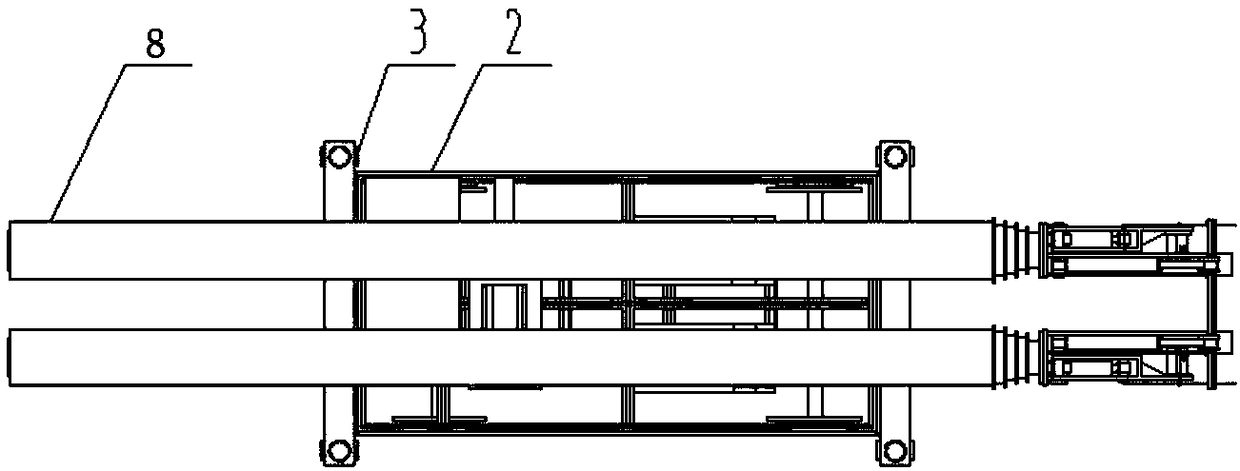

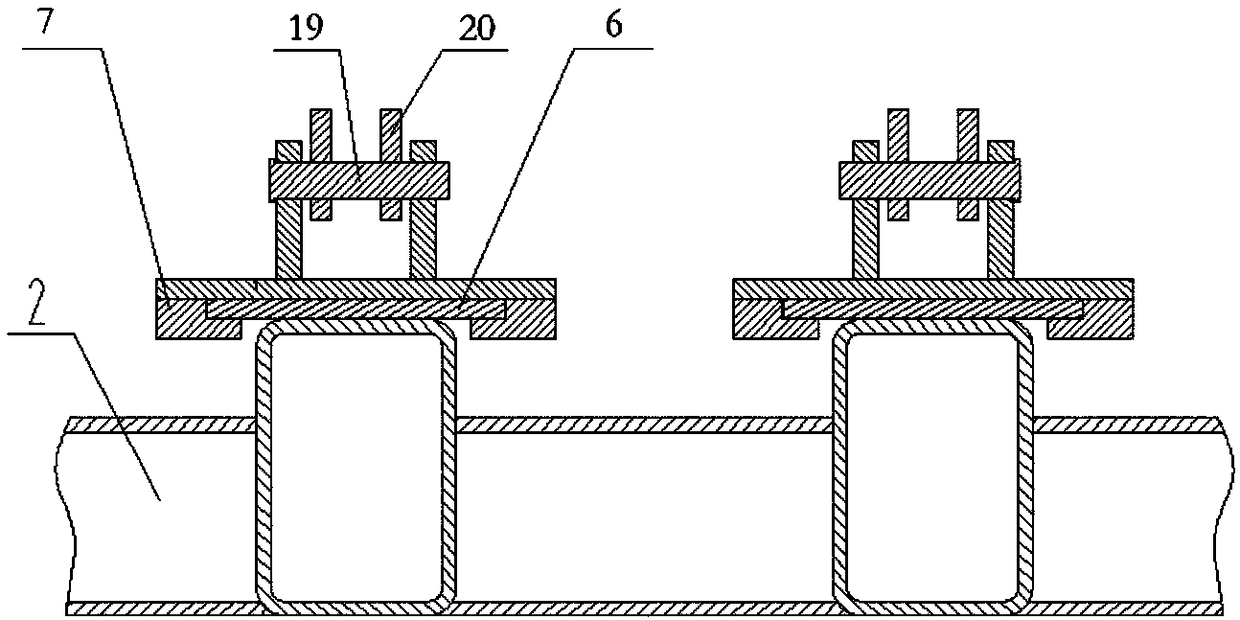

[0060] like Figure 1-Figure 6As shown, the anchor cable cutting machine of the present invention includes a traveling mechanism, a turning mechanism and a clamping and cutting mechanism for clamping and cutting the anchor cable. The upper part of the traveling mechanism is equipped with a turning mechanism, and the front end of the turning mechanism is installed with a clamping and cutting Mechanism; the traveling mechanism includes a walking wheel 1, a chassis 2 and a support leg 3, the walking wheel 1 is installed on the bottom of the chassis 2, and the support legs 3 are installed on both sides of the chassis. Outrigger oil cylinders are provided inside, and the outrigger oil cylinders expand and contract under working conditions so that the four outriggers 3 contact the ground to support the overall anchor cable cutting machine and are used to enhance the stability of the anchor cable cutting machine; the chassis 2 is equipped with The hydraulic oil tank 4 and the hydraul...

Embodiment 2

[0086] On the basis of Embodiment 1, the anchor cable cutting machine includes two telescopic arms 8, and the front end of each telescopic arm 8 is connected to a clamping and cutting mechanism. During cutting construction, the telescopic length of the two telescopic arms 8 is adjusted simultaneously. And the clamping and cutting mechanism ensures that the two telescopic arms 8 can be carried out synchronously.

Embodiment 3

[0088] On the basis of Embodiment 1, the difference is that the walking wheel 1 can adopt a crawler-type walking mechanism, and when walking on uneven ground, it can also cross obstacles and climb lower steps, and adopt a crawler-type walking mechanism Making the movement makes the movement of the cable cutter more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com