Pig feed production method

A production method and pig feed technology, applied in the field of pig feed production and breeding, can solve the problems of waste of raw materials and easy attachment to the crushing device, and achieve the effects of improving production efficiency, being easy to ripen and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

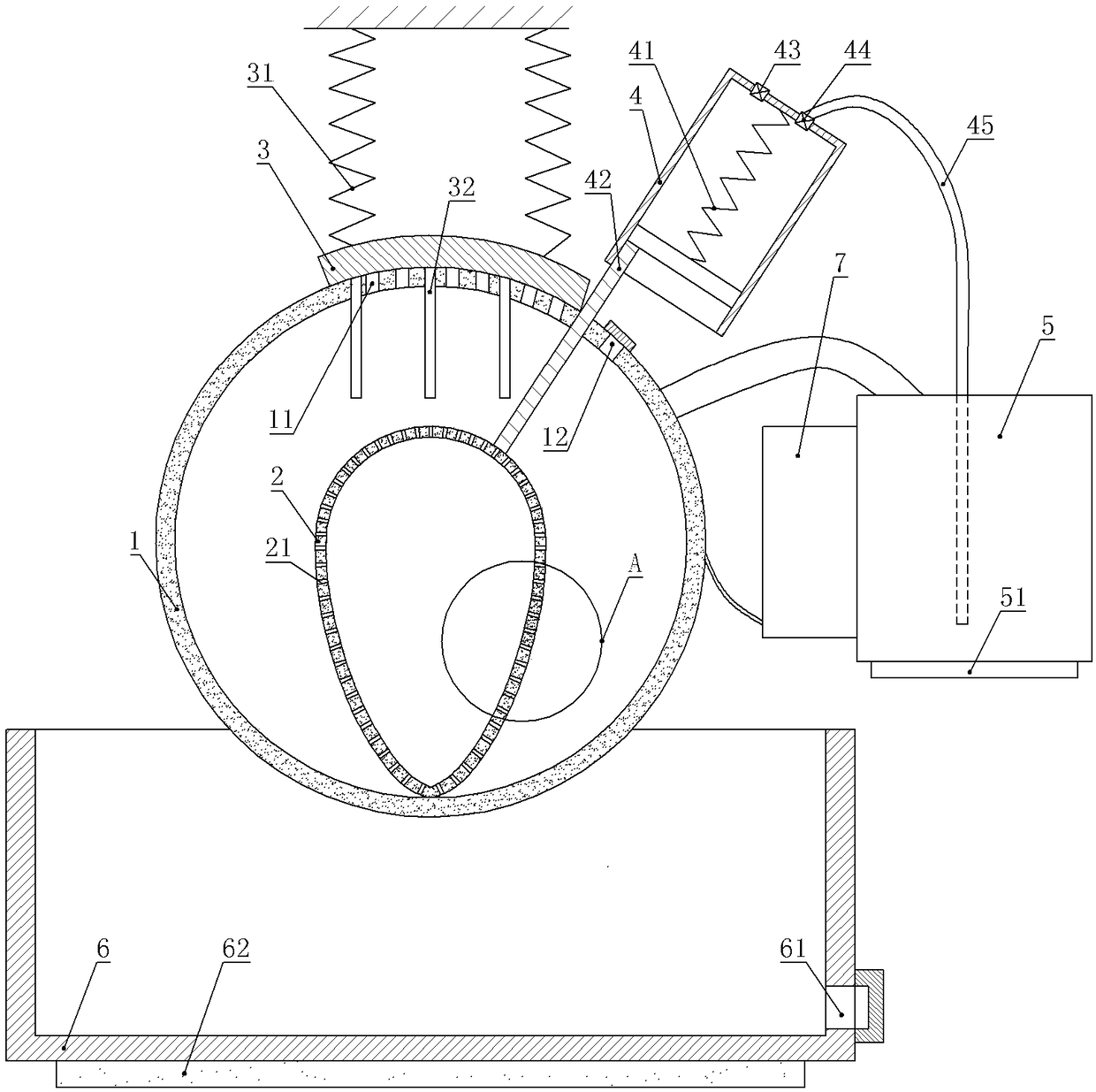

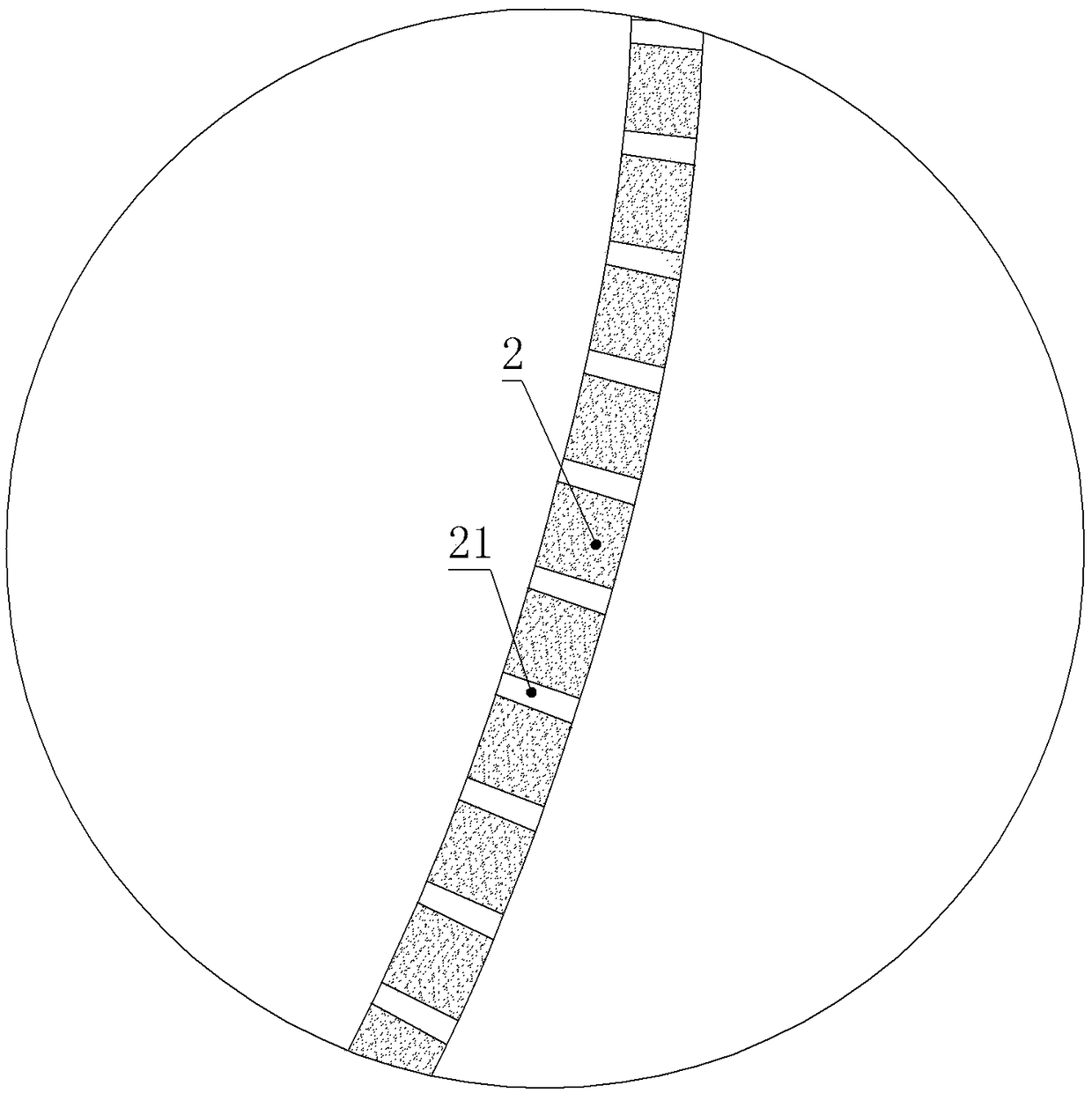

[0021] The following will be further described in detail through specific embodiments: extrusion barrel 1, extrusion hole 11, feed port 12, cam barrel 2, steam hole 21, closing block 3, compression spring 31, contact rod 32, closed cylinder 4, closed Spring 41, closing plate 42, inlet check valve 43, outlet check valve 44, inlet pipe 45, heating barrel 5, first heating element 51, collecting tank 6, discharge port 61, second heating element 62, storage water tank7.

[0022] The reference signs in the accompanying drawings of the specification include:

[0023] Pig feed production method, comprises the following steps:

[0024] (1) crushing for the first time, cutting the solid raw material into particles with a particle size of 0.2 to 1 cm;

[0025] (2) ripening, adopting pure water to poach the granules treated in step (1), the poaching time is 10-30min under standard atmospheric pressure, then adopting a filter screen with mesh number of 100 to filter, the granule raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com