Energy-saving and environment-friendly drying equipment for processing castings

An energy-saving and environment-friendly drying equipment technology, applied in the field of casting processing, can solve the problems of continuous operation, unfavorable long-term storage of castings, and rusting of castings, so as to improve water removal efficiency, reduce heat loss, and reduce energy consumption. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

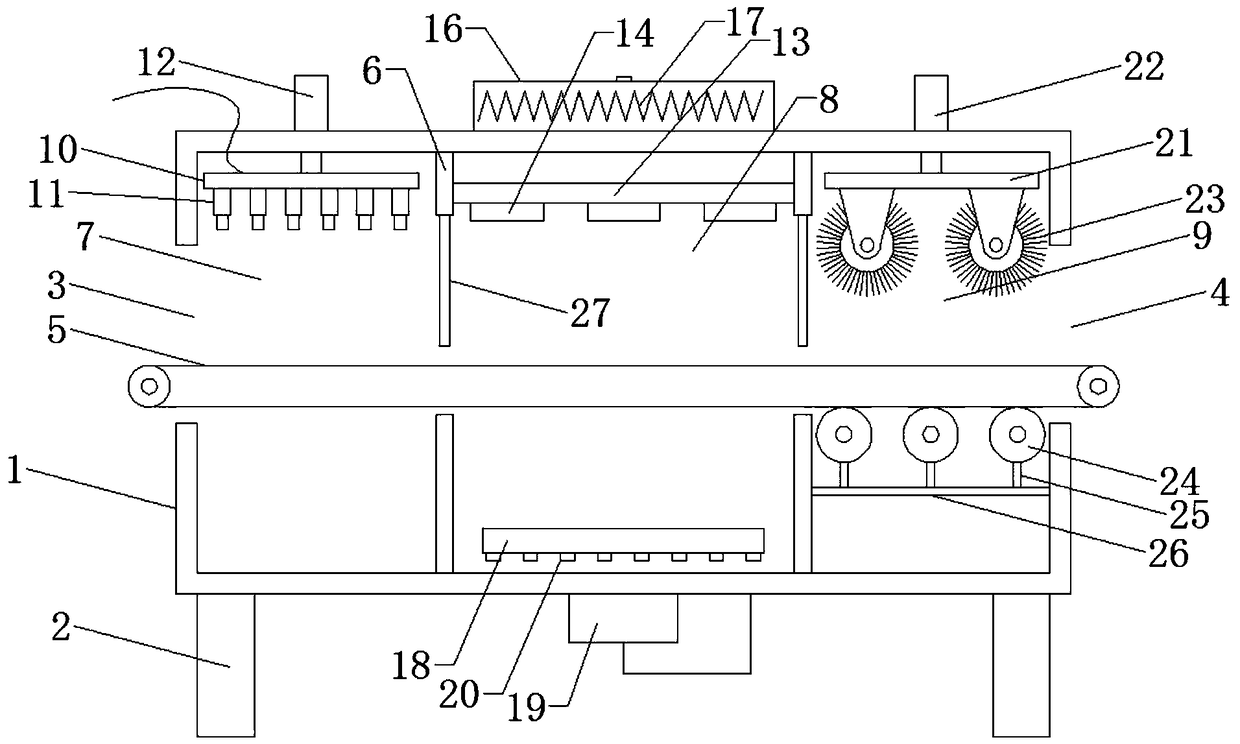

[0020] Please refer to the figure, in the embodiment of the present invention, an energy-saving and environment-friendly drying equipment for casting processing, including a shell 1, a leg 2, a feed port 3, a discharge port 4 and a conveyor belt 5; the legs 2 is fixed on the bottom of the shell 1 to support the shell 1, the feed port 3 and the discharge port 4 are set at the left and right ends of the shell 1 respectively, and the conveyor belt 5 is horizontally installed in the shell 1 , and the two ends pass through the feed port 3 and the discharge port 4 respectively, the conveyor belt 5 is driven by the transmission wheel, so that the castings located in the conveyor belt 5 pass through the 1, and the conveyor belt 5 is provided with a number of through holes 30. Make the water on the surface of the casting placed on the conveyor belt 5 flow down and fall into the housing 1 below the conveyor belt 5 .

[0021] Two sets of vertical partitions 6 are fixed inside the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com