Sectional type small-sized garbage incinerator

A garbage incinerator, segmented technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of increasing the calorific value of garbage, difficulty in setting up a leachate treatment system in a leachate discharge pool, and reducing moisture content, etc. problems, to achieve the effect of easy intelligent product development, intelligent product development, and high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

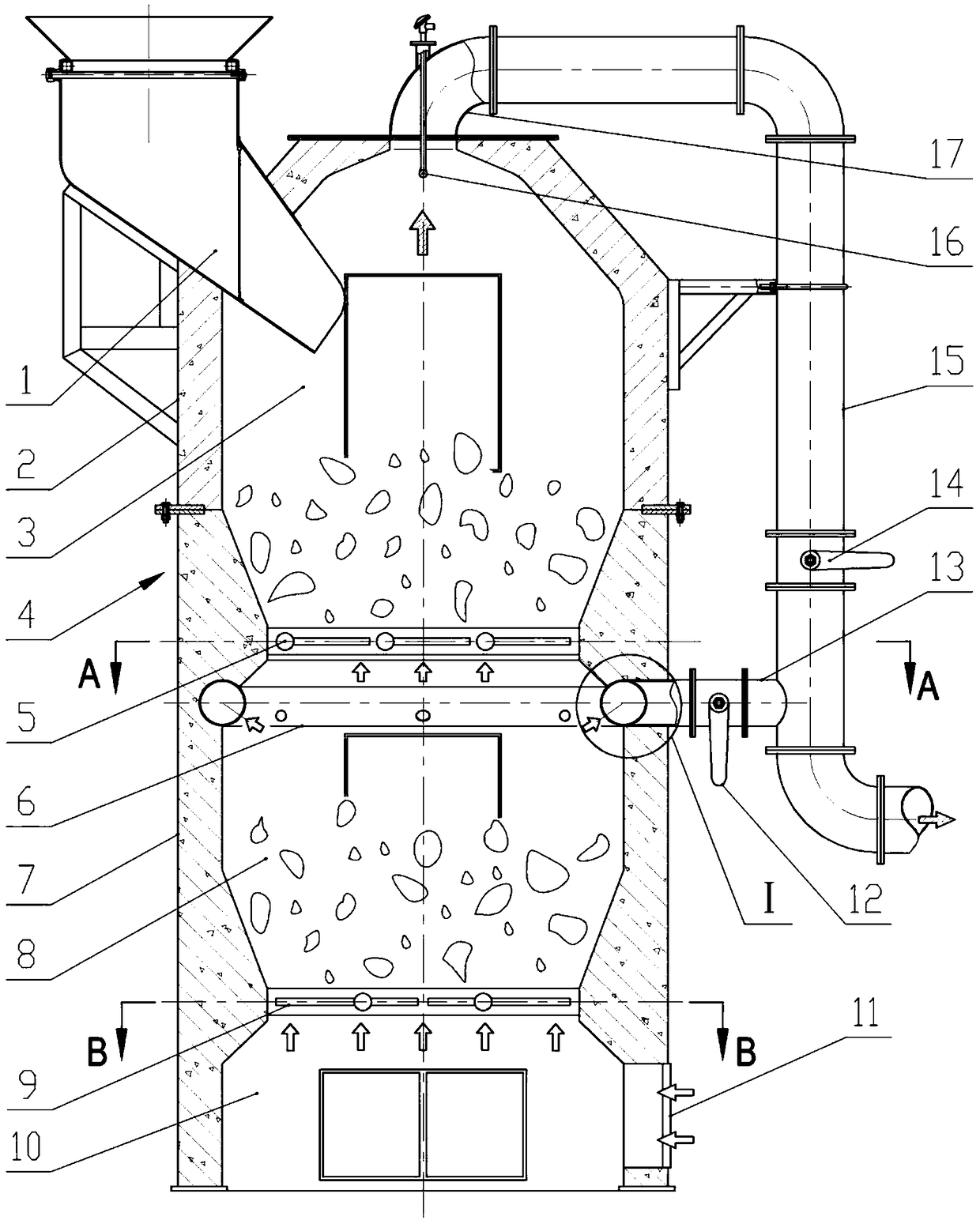

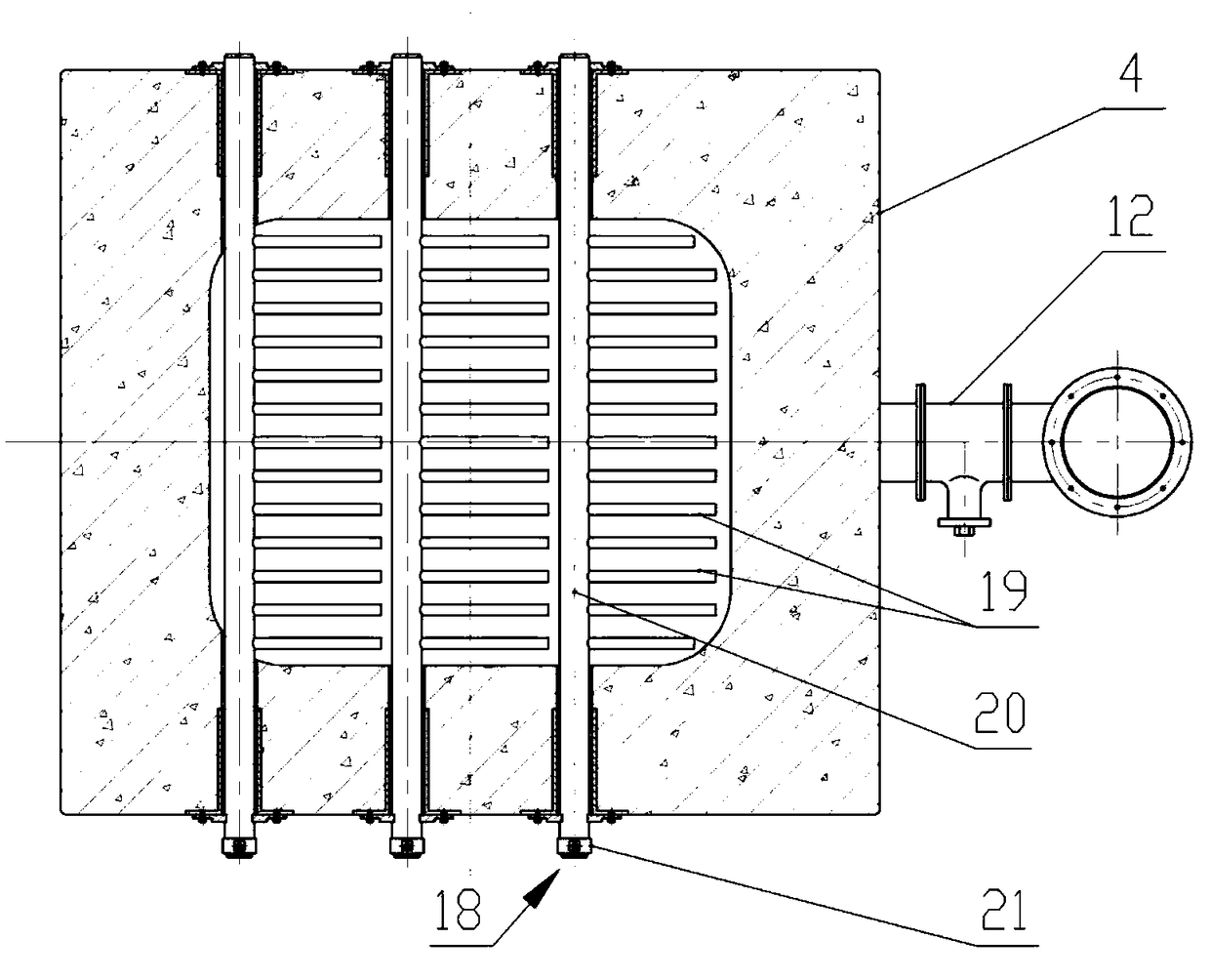

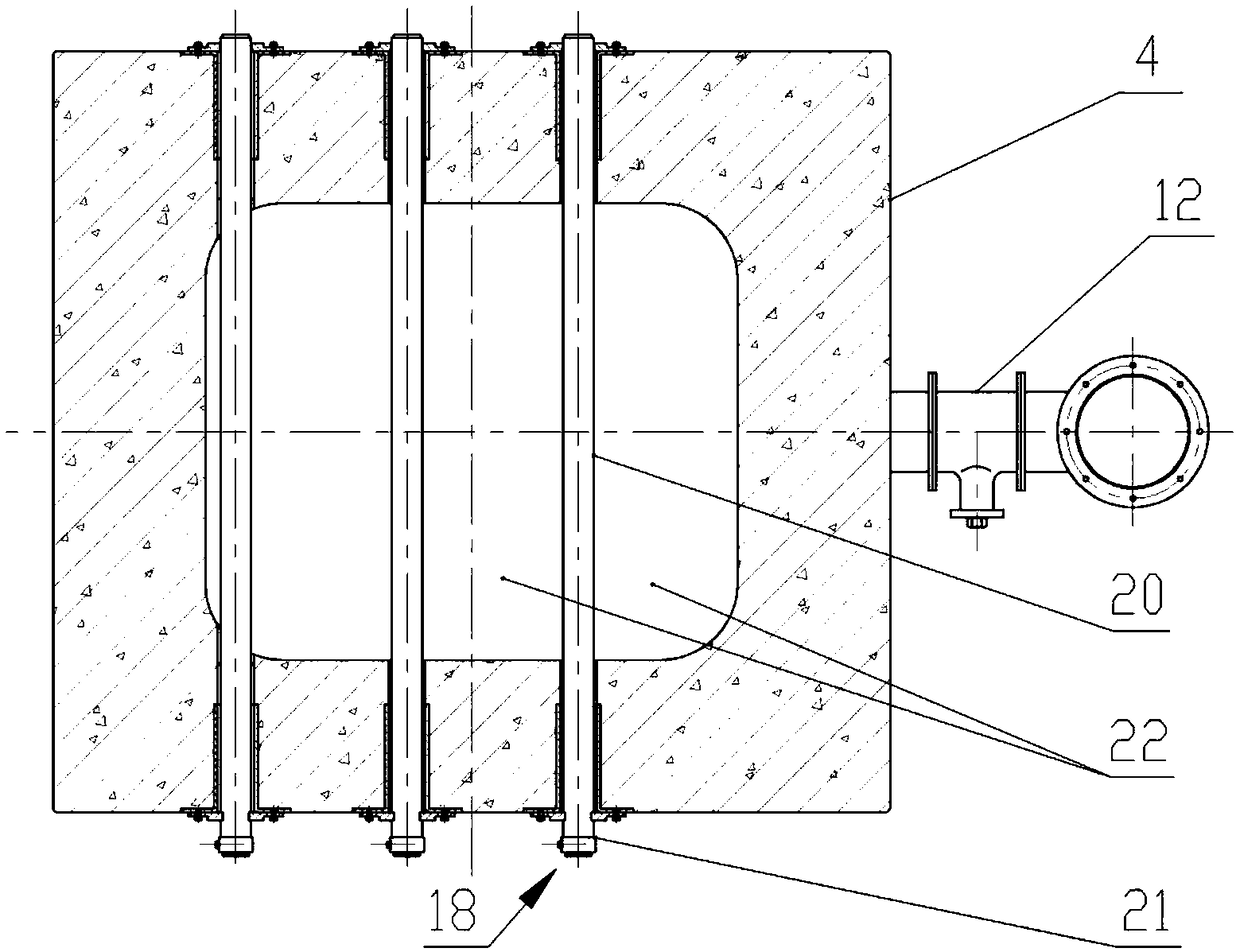

[0049] The invention provides a segmented small-scale garbage incinerator structure, which divides the burning of garbage into two links of drying and burning. In the drying link, the low calorific value garbage with high original moisture content is controlled Carry out preheating, drying, and at the end of the drying, partially ignite the garbage to form a fire head, and then let the garbage re-stack and enter the combustion process. After preheating and drying the garbage, and dispersing the fire, it is more conducive to garbage incineration. Therefore, the incinerator proposed by the present invention has a good effect on domestic garbage with high moisture content and sanitation garbage mixed with more inert and compact components. adaptability.

[0050] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com