A Novel Viscous Damper with Adjustable Damping Coefficient

A technology of viscous damper and damping coefficient, applied in shock absorbers, shock absorbers, solid shock absorbers, etc., can solve the problems of poor reliability, high cost, ineffective controllers and sensors, and achieve simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

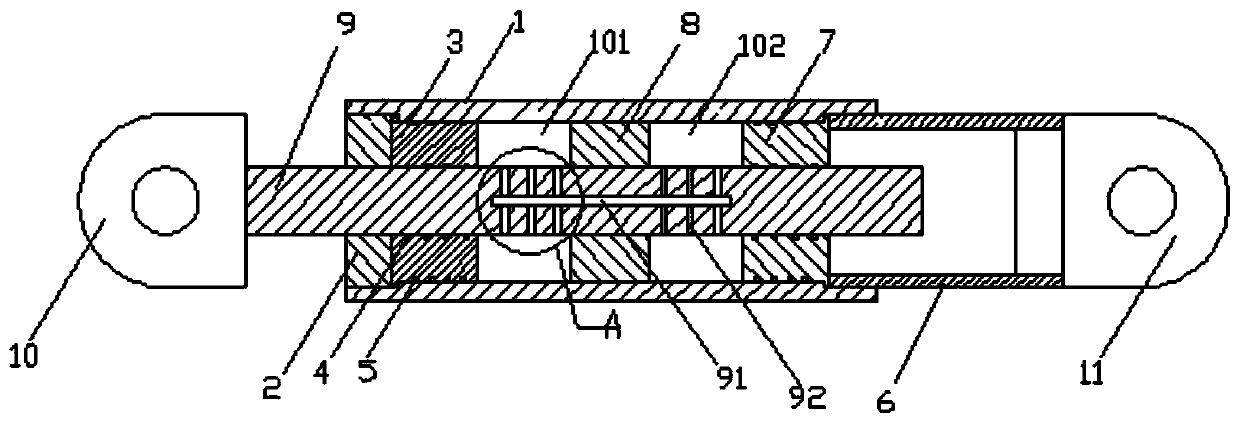

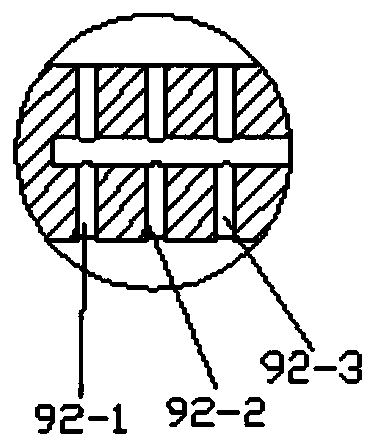

[0041] like figure 1 , figure 2 As shown, it is a new type of viscous damper with adjustable damping coefficient of the present invention, which consists of cylinder body 1, front end cover 2, front guide sleeve 3, dynamic seal 4, static seal 5, auxiliary cylinder 6, rear Cover 7, piston 8, piston rod 9, front earring 10 and rear earring 11 are formed;

[0042] The inner wall of the front end of the cylinder body 1 is provided with a first groove, and the front end cover 2 is fixed in the first groove, and the front guide sleeve 3 is arranged behind the front end cover 2, and the front guide sleeve 3 is arranged on the front end cover 2 to prevent the front The guide sleeve 3 moves forward, and the outer wall of the front guide sleeve 3 is provided with a first lug, and the first lug is engaged with the first groove to prevent the front guide sleeve 3 from moving backward. The seal 4, the outer wall of the front guide sleeve 3 is provided with a static seal 5, and the stati...

Embodiment 2

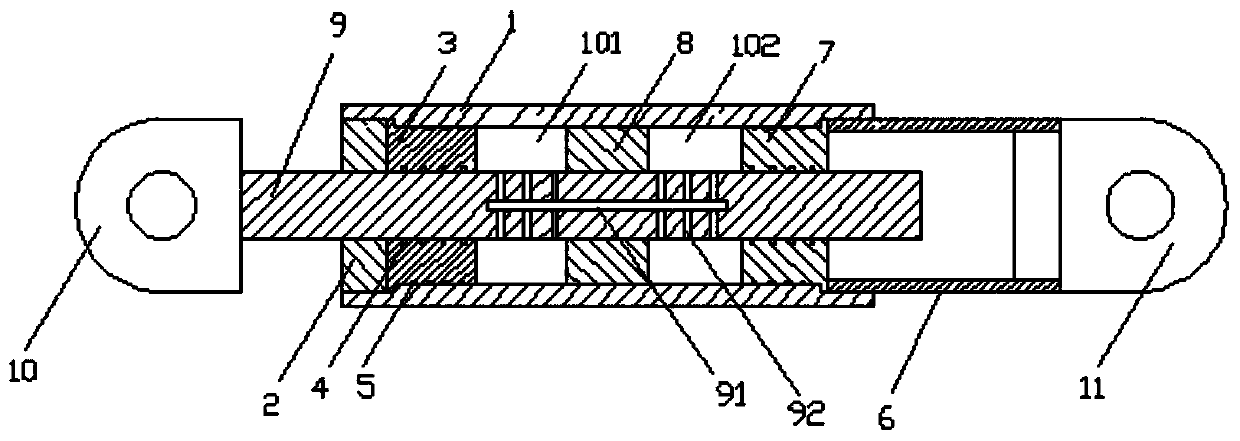

[0056] like Image 6 , Figure 7 As shown, it is another new viscous damper with adjustable damping coefficient of the present invention, which consists of a cylinder body 1, a front cover 2, a front guide sleeve 3, a dynamic seal 4, a static seal 5, an auxiliary cylinder 6, a rear Composed of guide sleeve 7, piston 8, piston rod 9, front earring 10 and rear earring 11;

[0057] The inner wall of the front end of the cylinder body 1 is provided with a first groove, and the front end cover 2 is fixed in the first groove, and the front guide sleeve 3 is arranged behind the front end cover 2, and the front guide sleeve 3 is arranged on the front end cover 2 to prevent the front The guide sleeve 3 moves forward, and the outer wall of the front guide sleeve 3 is provided with a first lug, and the first lug is engaged with the first groove to prevent the front guide sleeve 3 from moving backward. The seal 4, the outer wall of the front guide sleeve 3 is provided with a static seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com