An environment-friendly dust collection mechanism for printing equipment

A technology of vacuuming mechanism and printing equipment, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of dust flying and polluting the environment, inability to collect dust, etc., to avoid production costs and facilitate disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

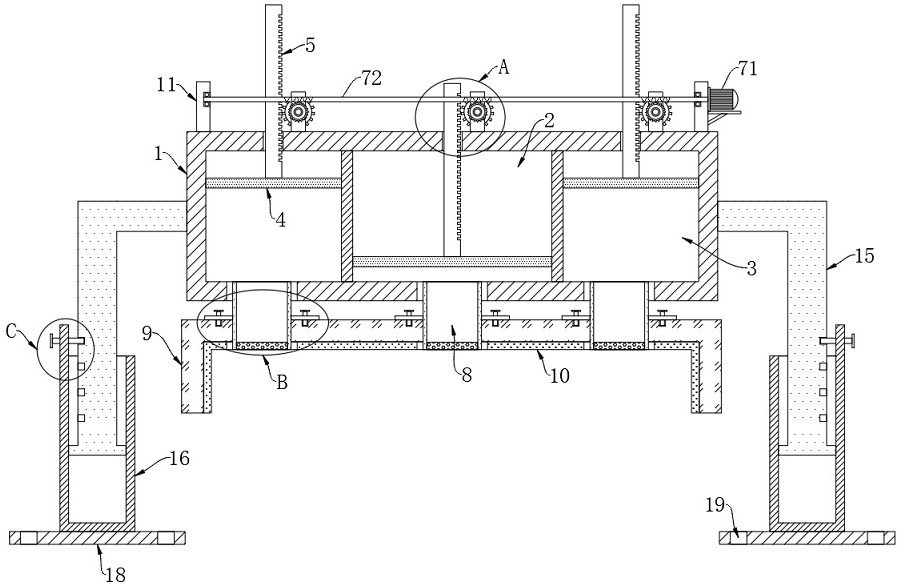

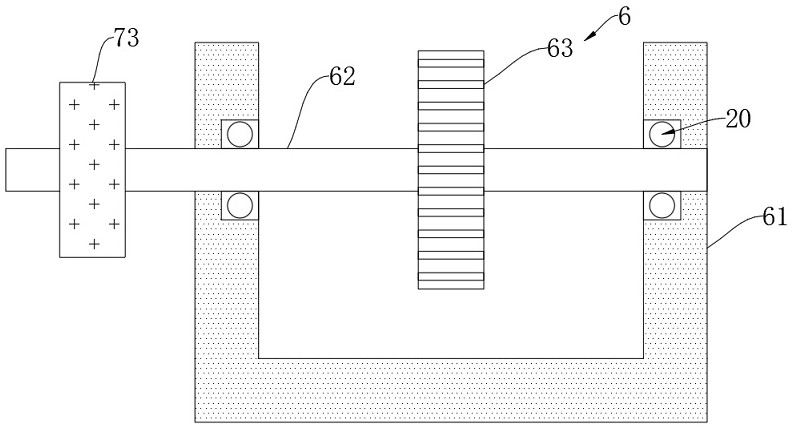

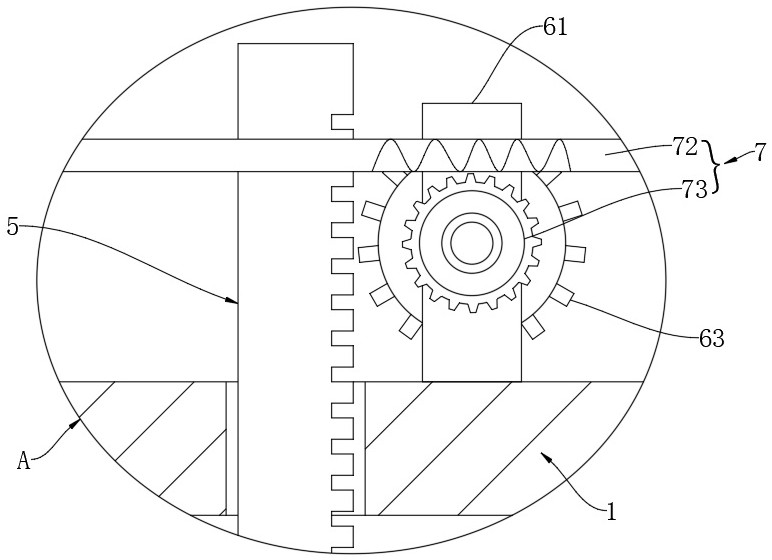

[0034] Such as Figure 1-5 As shown, an environment-friendly dust collection mechanism for printing equipment includes a box body 1, and the side walls on both sides of the box body 1 are fixedly connected with support rods 15, and the support rods 15 are designed in an L shape, and the setting of the L-shaped support rods 15 Stable support can be given to the box body 1. At the same time, the L-shaped design facilitates the connection between the support rod 15 and the box body 1. The support rod 15 is slidably connected to the hollow rod 16, and a limit mechanism 17 is arranged between the hollow rod 16 and the support rod 15. The mutual sliding cooperation of the support rod 15 and the hollow rod 16 can adjust the height of the support rod 15 by sliding the support rod 15, and then can regulate the height of the box body 1 under the drive of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com