A method of operating a pressure control system

A technology of pressure control and operation method, applied in the direction of fluid pressure actuating device, valve absorbing fluid energy device, mechanical equipment, etc., can solve the problem that the ball cannot be accurately aligned with the valve seat mouth, the size cannot be adjusted in real time, and the function is single. problems, to achieve the effect of convenient daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

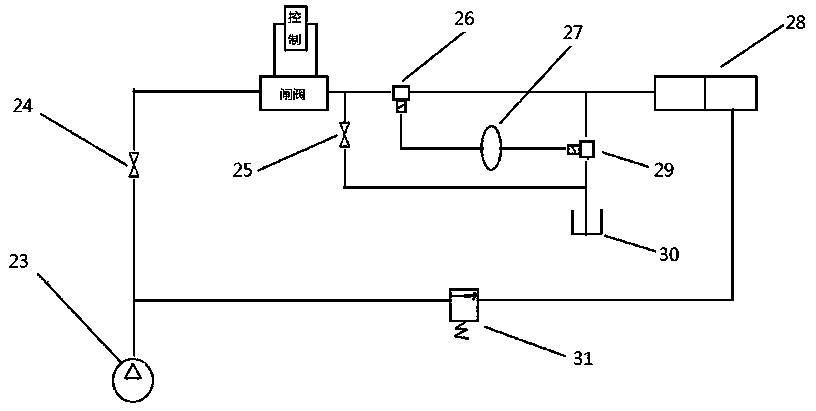

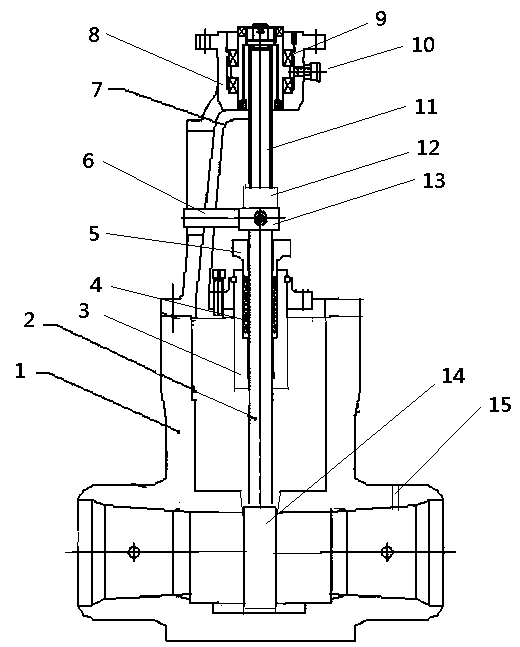

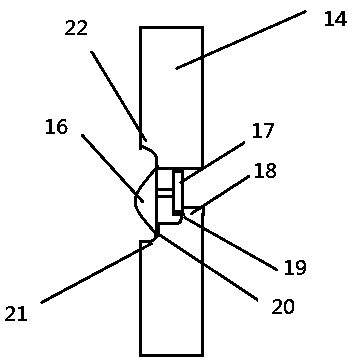

[0036] As shown in the figure: a method for operating a pressure control system, the pressure control system includes a pump, a first switch, a second switch, a first three-way valve, an accumulator, a hydraulic cylinder, a second three-way valve, and an oil tank , Solenoid valve, gate valve, control device; the operation method includes a driving method, a pressure relief method, a decompression energy storage method, and an energy storage feedback method;

[0037] As shown in the figure: the driving method is as follows: the liquid in the pump is connected to the first cavity of the hydraulic cylinder through the main circuit, and the second cavity of the hydraulic cylinder is connected through the auxiliary circuit; the main circuit includes the first cavity Switch, gate valve, first three-way valve; the auxiliary circuit includes the solenoid valve; by respectively injecting liquid into the main circuit and injecting liquid into the auxiliary circuit, the first cavity and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com