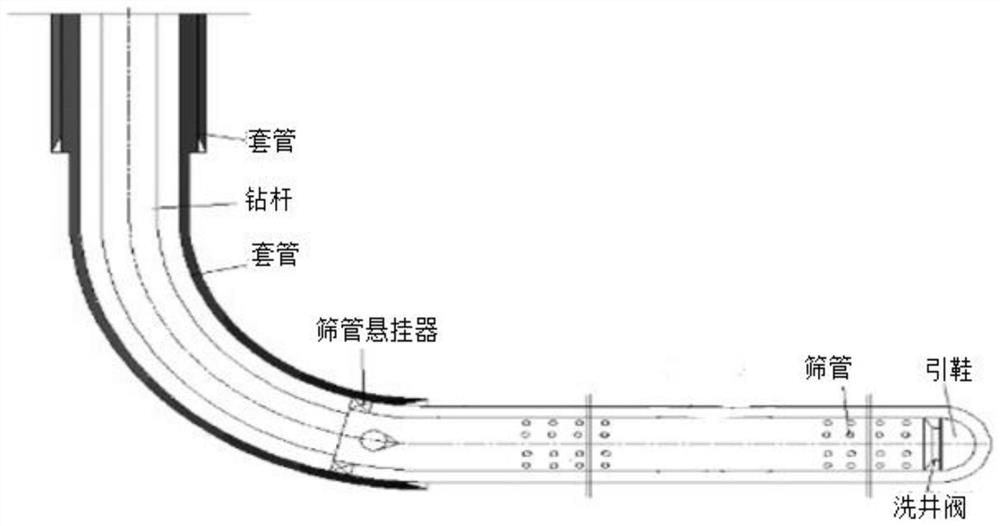

A method of temporary plugging volume fracturing for highly deviated wells with screens

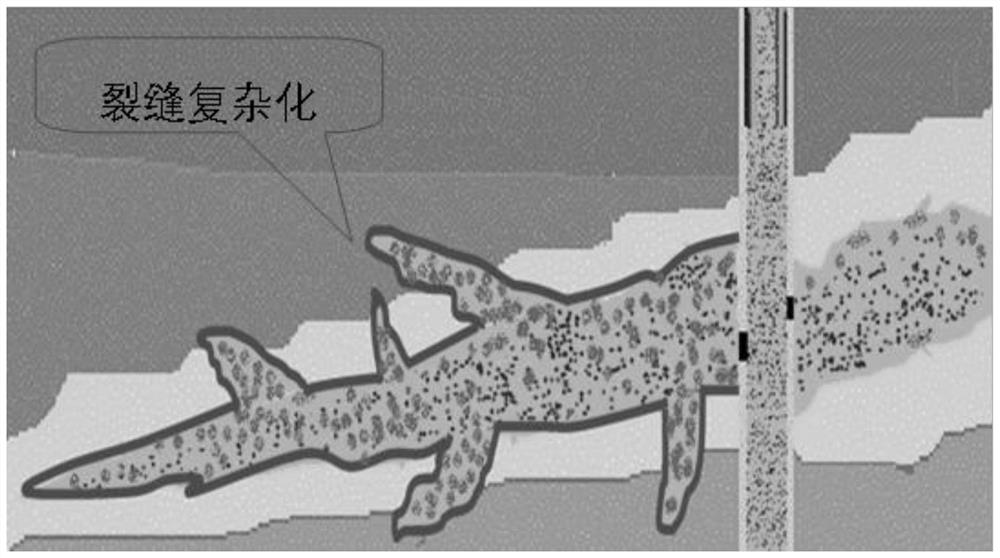

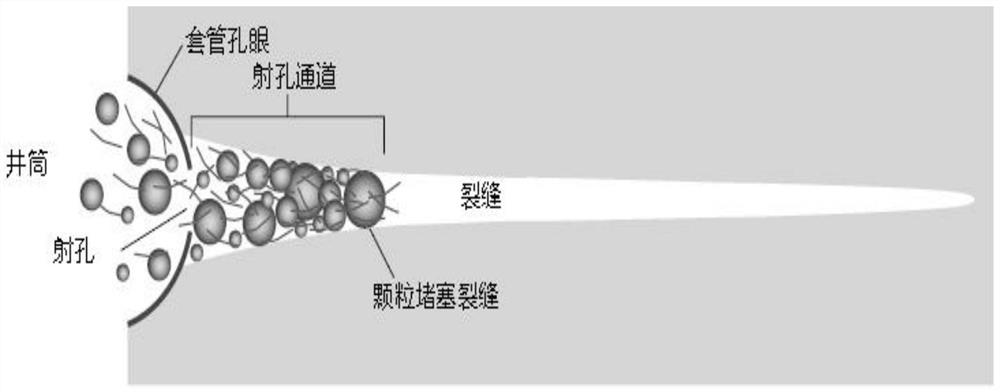

A technology for volume fracturing and high-inclination wells, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve problems such as large load changes, large torque and tension losses, and difficult interpretation of downhole conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] It should be understood that terms such as "having", "comprising" and "including" as used herein do not assign the presence or addition of one or more other elements or combinations thereof.

[0039] The technical method for temporary plugging volume fracturing in a highly deviated well with a screen tube includes the following steps:

[0040]Step S1, comprehensively consider the basic conditions of the construction well reservoir, including the petrological characteristics, rock mechanical characteristics, physical properties, heterogeneity characteristics, oil layer distribution characteristics, reservoir fluid properties, temperature and pressure systems, in-situ stress characteristics and location of the reservoir section. Factors such as the injection-production wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com