Novel packer release joint

A packer, a new type of technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of difficulty in dropping hands, very high operation requirements, affecting the diameter of the pipe, etc., to achieve small rotational torque, reliable insertion, The effect of ensuring the sealing of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

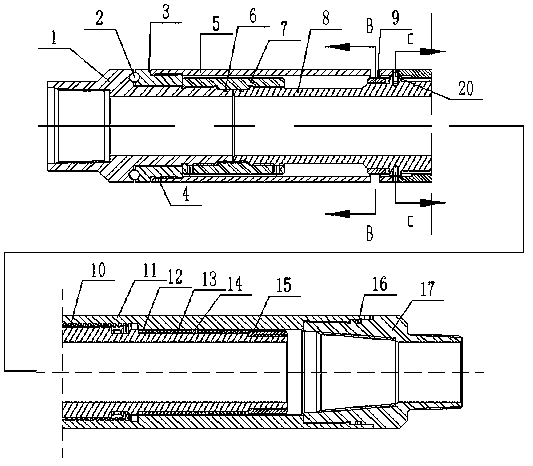

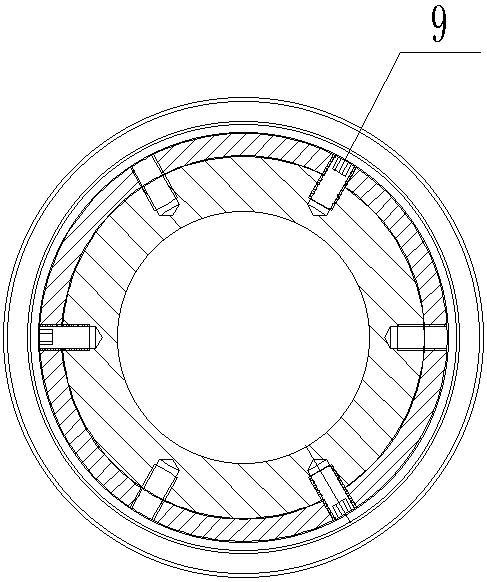

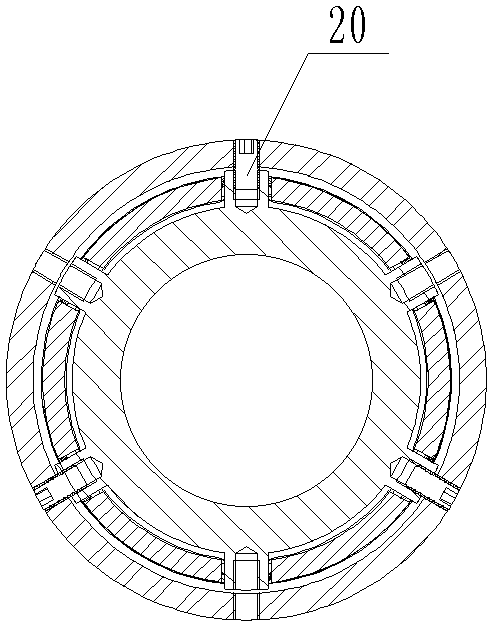

[0037] Specific embodiment 1: as figure 1 As shown, before entering the well, connect the drop-off joint and the packer on the ground. The packer is a mechanical seat packer. After installing the shear nail I20, the mandrel 8 and the jaw sleeve 11 are relatively fixed. , send the drop-off joint and the packer down, and then set the packer in place, and rotate the pipe string. Due to the action of the shear nail I20, the mandrel 8 will be together with the jaw sleeve 11 and the elastic jaw 10. Rotate, when the number of turns of the rotating seat packer reaches the required number of turns, slowly press down to make the pipe string under pressure. Stuck, if the packer slip seat is stable, continue to press down the pipe string, the shear nail I20 will be cut off, and the seat seal packer will be closed at the same time. The lower end surface of 5 is in contact with the upper end surface of the claw sleeve 11, the upper end surface of the outer sleeve 5 is connected with the be...

specific Embodiment 2

[0038] Specific embodiment 2: as Figure 4 As shown, before entering the well, connect the drop-off joint with the packer on the ground. The packer is a hydraulic seated packer. To seal the packer, press down to make the pipe string under pressure. At this time, the lower end surface of the outer sleeve 5 and the upper end surface of the claw sleeve 11 fit together to prevent debris in the well from entering the threaded joint. Press down the pipe string so that the lower end surface of the outer sleeve 5 is in contact with the upper end surface of the claw sleeve 11, and the upper end surface of the outer sleeve 5 is connected with the bearing cover 3, and the pipe string is rotated forward, and the elastic claw 10 spirals up until all the threads are unscrewed. Realize throwing away. During the process of pressing down and rotating the pipe string, the pressure always acts on the steel ball 2 and the bearing cover 3. At this time, the anchoring claw is not subject to pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com