Segmented material change pool water gate for nuclear power plant and assembly method thereof

An assembly method and segmented technology, applied in the field of nuclear power, can solve problems such as inconvenient maintenance and replacement, achieve the effects of shortening the overhaul period, reducing sealing performance, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

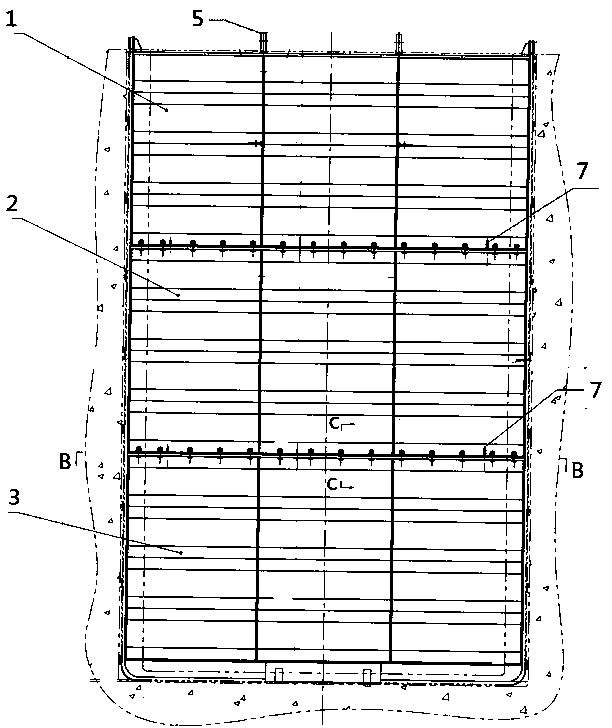

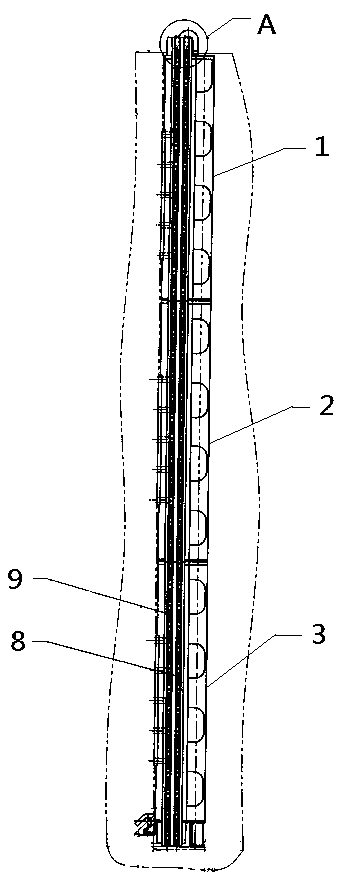

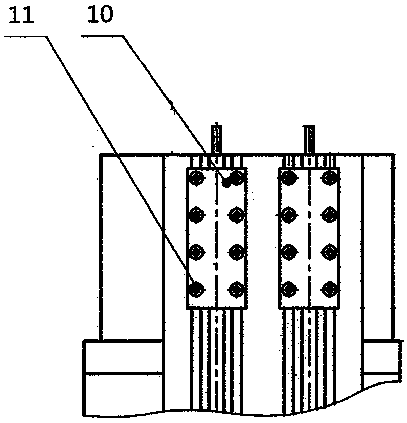

[0059] see Figure 1-18 , the present invention relates to a segmented refueling pool water gate, comprising an upper segment 1, a middle segment 2 and a lower segment 3, and a coupling gasket 4 is arranged between the upper segment 1 and the middle segment 2 The bolts pass through the top surface of the middle section 2, the joint gasket 4 and the bottom surface of the upper section 1 in turn and are connected by nuts 12. A joint gasket 4 is arranged between the middle section 2 and the lower section 3, and the bolts pass through in turn The top surface of the lower section 3, the joint gasket 4 and the bottom surface of the middle section 2 are connected by nuts 12, two lifting lugs 5 are provided on the top of the upper section 1, and a tether ring 6 is provided on the side of the upper section 1. Two guide pins 7 are provided on the top of the middle section 2 and the lower section 3, and holes corresponding to the guide pins 7 are provided at the bottom of the upper secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com