Mechanical arm and preparation method thereof, and dispensing robot using mechanical arm

A technology of dispensing robots and robotic arms, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as heavy workload, access, and easy corrosion, and achieve improved durability and corrosion resistance. The dispensing environment is clean, Avoid easy-to-pour effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

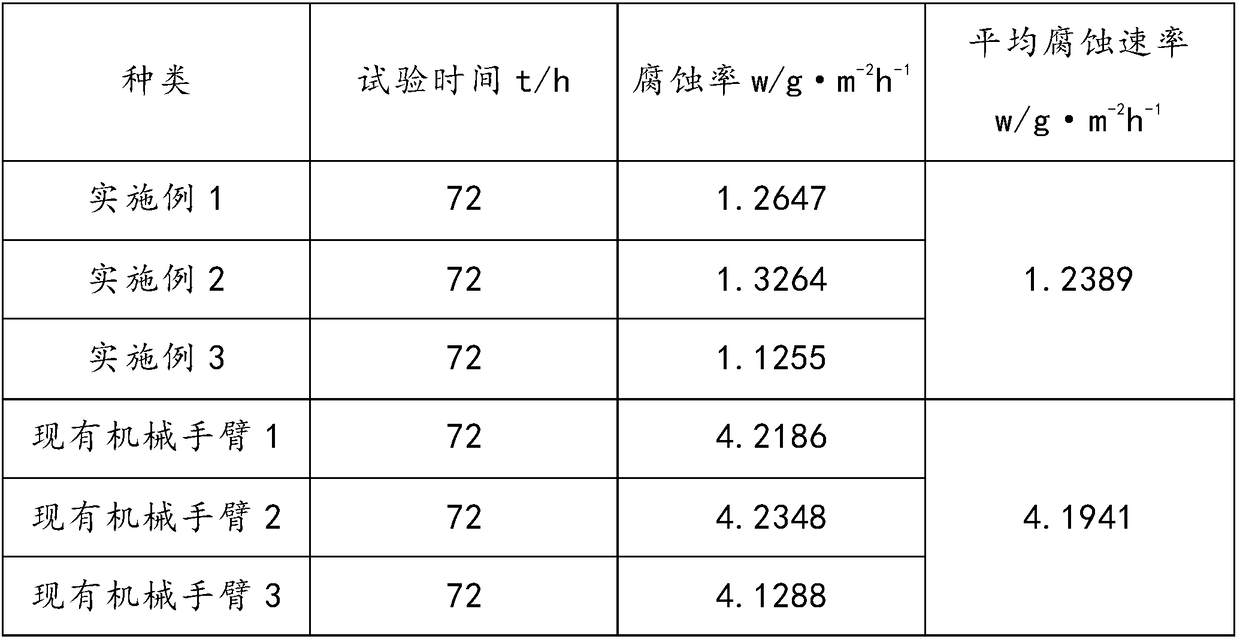

Embodiment 1

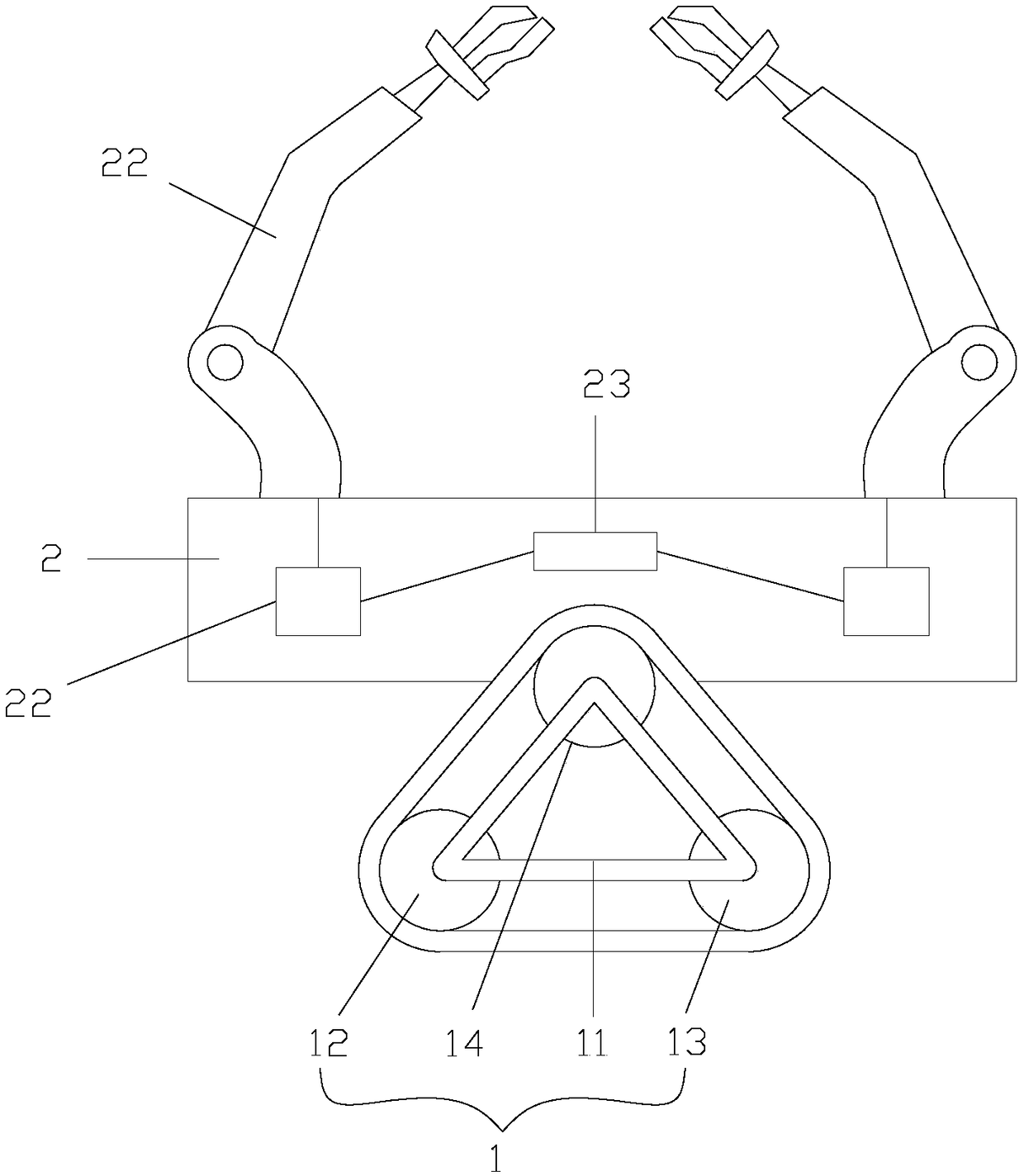

[0026] refer to figure 1 As shown, a mechanical arm is composed of the following mass percentage components: C: 1.5%, Si: 0.2%, Cr: 0.3%, V: 0.15%, Zr: 0.15%, Ce: 0.55%, Ir: 0.12 %, Li: 0.75%, Hf: 0.02%, Mg: 0.05%, Cu: 0.35%, Ga: 0.45%, Ni: 0.25%, Sc: 0.004%, Mo: 0.06%, Al: 0.8%, Nb: 0.2 , the balance being Fe.

[0027] A preparation method of a mechanical arm, comprising the following steps:

[0028] 1) First put AL into the furnace to melt, and when it is heated to 700-720°C, then add C, Si, Cr, V, Zr, Ce, Ir, Li and Hf, and stir for 20-30min to make the components in the melt mix evenly;

[0029] 2) When the melt temperature is 750-760°C, add Mg, Cu, Ga, Ni, Sc, Mo, Al, Nb and Fe, and stir for 20-25 minutes to mix the ingredients in the melt evenly;

[0030] 3) When the melt temperature is 720-740°C, use argon spray powder for refining, the refining time is 45 minutes, and remove the scum on the liquid surface after refining;

[0031] 4) After refining, let the melt st...

Embodiment 2

[0038]A mechanical arm consisting of the following mass percentage components: C: 1.7%, Si: 0.4%, Cr: 0.5%, V: 0.25%, Zr: 0.35%, Ce: 0.75%, Ir: 0.14%, Li : 0.85%, Hf: 0.04%, Mg: 0.15%, Cu: 0.55%, Ga: 0.55%, Ni: 0.35%, Sc: 0.008%, Mo: 0.08%, Al: 1.1%, Nb: 0.4, balance For Fe.

[0039] A preparation method of a mechanical arm, comprising the following steps:

[0040] 1) First put AL into the furnace to melt, and when it is heated to 700-720°C, then add C, Si, Cr, V, Zr, Ce, Ir, Li and Hf, and stir for 20-30min to make the components in the melt mix evenly;

[0041] 2) When the melt temperature is 750-760°C, add Mg, Cu, Ga, Ni, Sc, Mo, Al, Nb and Fe, and stir for 20-25 minutes to mix the ingredients in the melt evenly;

[0042] 3) When the melt temperature is 720-740°C, use argon spray powder for refining, the refining time is 45 minutes, and remove the scum on the liquid surface after refining;

[0043] 4) After refining, let the melt stand for 40 minutes;

[0044] 5) Cast ...

Embodiment 3

[0050] A mechanical arm consisting of the following components by mass percentage: C: 1.6%, Si: 0.3%, Cr: 0.4%, V: 0.2%, Zr: 0.25%, Ce: 0.65%, Ir: 0.13%, Li : 0.8%, Hf: 0.03%, Mg: 0.1%, Cu: 0.45%, Ga: 0.5%, Ni: 0.3%, Sc: 0.006%, Mo: 0.07%, Al: 0.95%, Nb: 0.3, balance For Fe.

[0051] A preparation method of a mechanical arm, comprising the following steps:

[0052] 1) First put AL into the furnace to melt, and when it is heated to 700-720°C, then add C, Si, Cr, V, Zr, Ce, Ir, Li and Hf, and stir for 20-30min to make the components in the melt mix evenly;

[0053] 2) When the melt temperature is 750-760°C, add Mg, Cu, Ga, Ni, Sc, Mo, Al, Nb and Fe, and stir for 20-25 minutes to mix the ingredients in the melt evenly;

[0054] 3) When the melt temperature is 720-740°C, use argon spray powder for refining, the refining time is 45 minutes, and remove the scum on the liquid surface after refining;

[0055] 4) After refining, let the melt stand for 40 minutes;

[0056] 5) Cast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com