Formula and production process for ceramic storage tank

A ceramic and formula technology, applied in the field of ceramic storage tank formula and production technology, can solve the problems such as inability to produce large-capacity storage tanks and fermentation tanks, inability to use, and technology unable to solve leakage problems, and achieve the effect of being beneficial to reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: ceramic storage tank, made through the following steps:

[0022] Step 1: Preliminary treatment of raw materials, stacking Huguan green gangue for seven to eight months, then calcining at 600-800°C for 2-3 hours, manually washing feldspar and quartz to remove surface impurities;

[0023] Step 2: Crushing treatment of raw materials, the raw materials Huguan green gangue, quartz, and feldspar are coarsely crushed in a jaw crusher, and then intermediately crushed in a wet wheel, and then 60 parts of Huguan green gangue are taken, Mix 15 parts of sandstone clinker, 10 parts of quartz, 25 parts of feldspar, and 5 parts of kaolin into the barrel of the ball mill, and add 50-150 parts of water for ball milling;

[0024] Step 3: Perform iron removal treatment on the raw materials after ball milling in step 2, and use a strong magnetic separator with an induction intensity above 20,000 GS to remove iron;

[0025] Step 4: Pass the raw material after iron removal in ...

Embodiment 2

[0032] Embodiment 2: ceramic storage tank, made through the following steps:

[0033] Step 1: Preliminary treatment of raw materials, stacking Huguan green gangue for seven to eight months, then calcining at 600-800°C for 2-3 hours, manually washing feldspar and quartz to remove surface impurities;

[0034] Step 2: Crushing treatment of raw materials. Raw materials such as Huguan green gangue, quartz, and feldspar are coarsely crushed in a jaw crusher, and then intermediately crushed in a wet wheel, and then 80 parts of Huguan green gangue, Mix 25 parts of sand and gravel clinker, 20 parts of quartz, 40 parts of feldspar, and 15 parts of kaolin into the barrel of the ball mill, and add 50-150 parts of water for ball milling;

[0035] Step 3: Perform iron removal treatment on the raw materials after ball milling in step 2, and use a strong magnetic separator with an induction intensity above 20,000 GS to remove iron;

[0036] Step 4: Pass the raw material after iron removal in...

Embodiment 3

[0043] Embodiment 3: ceramic storage tank, made through the following steps:

[0044] Step 1: Preliminary treatment of raw materials, stacking Huguan green gangue for seven to eight months, and then calcining at 600-800°C for 2-3 hours, manually washing feldspar and quartz to remove surface impurities;

[0045] Step 2: Crushing treatment of raw materials, the raw materials Huguan green gangue, quartz, and feldspar are roughly crushed in a jaw crusher, and then intermediately crushed in a wet wheel, and then 68 parts of Huguan green gangue, 19 parts of sand and gravel clinker, 16 parts of quartz, 27 parts of feldspar, and 12 parts of kaolin are mixed and loaded into the barrel of the ball mill, and 50-150 parts of water are added for ball milling;

[0046] Step 3: Perform iron removal treatment on the raw materials after ball milling in step 2, and use a strong magnetic separator with an induction intensity above 20,000 GS to remove iron;

[0047] Step 4: Pass the raw material...

PUM

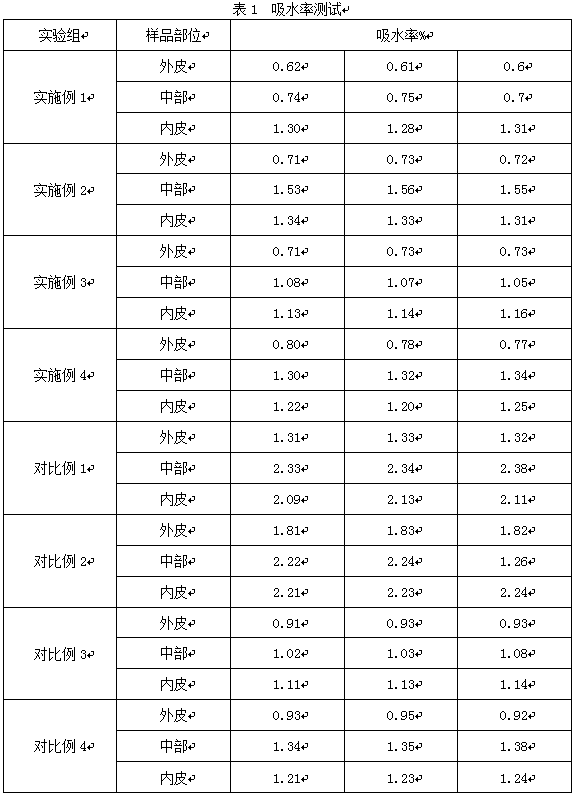

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com