Efficient and intelligent bottle cap mounting robot arm

A technology for robotic arms and bottle caps, applied in the field of robotic arms, can solve the problems of increased floor space, inability to adjust equipment, and high prices, and achieve the effects of improving work efficiency, preventing offset, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

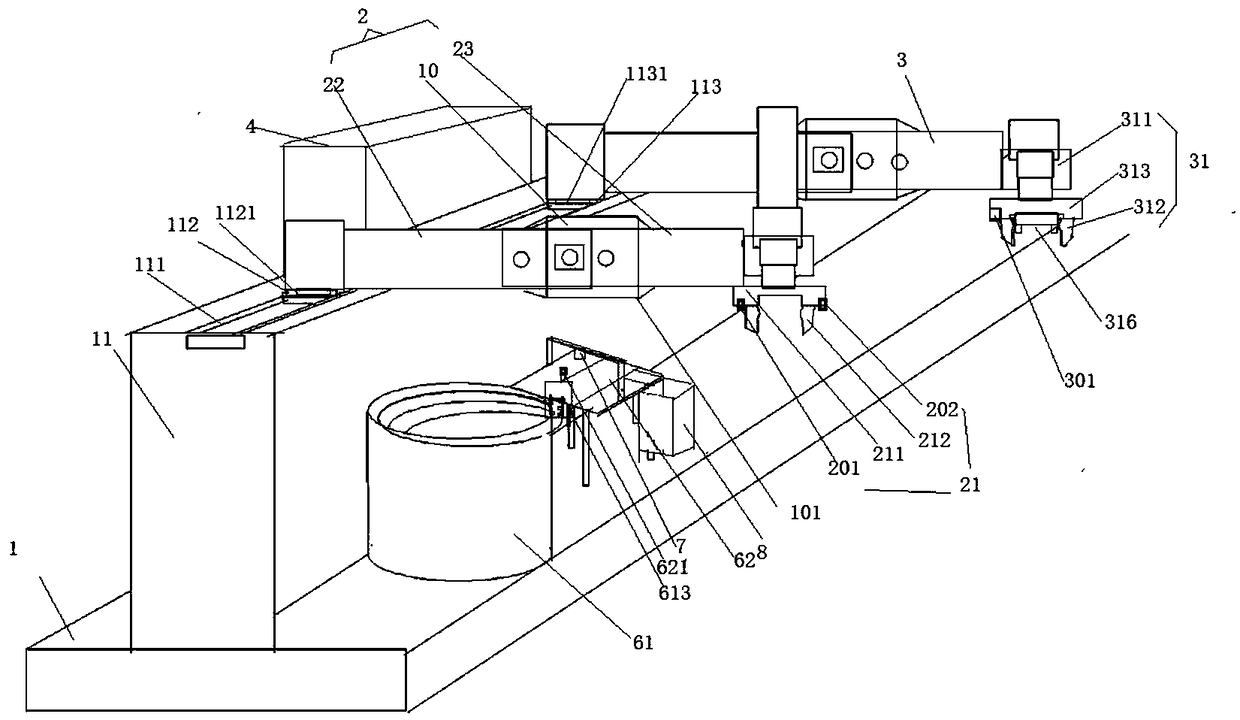

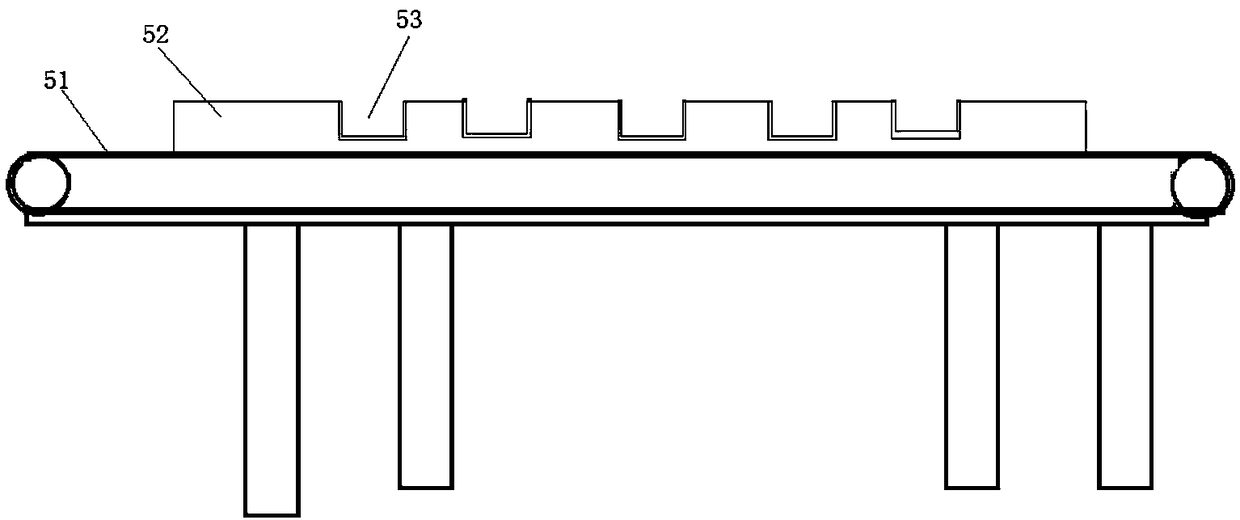

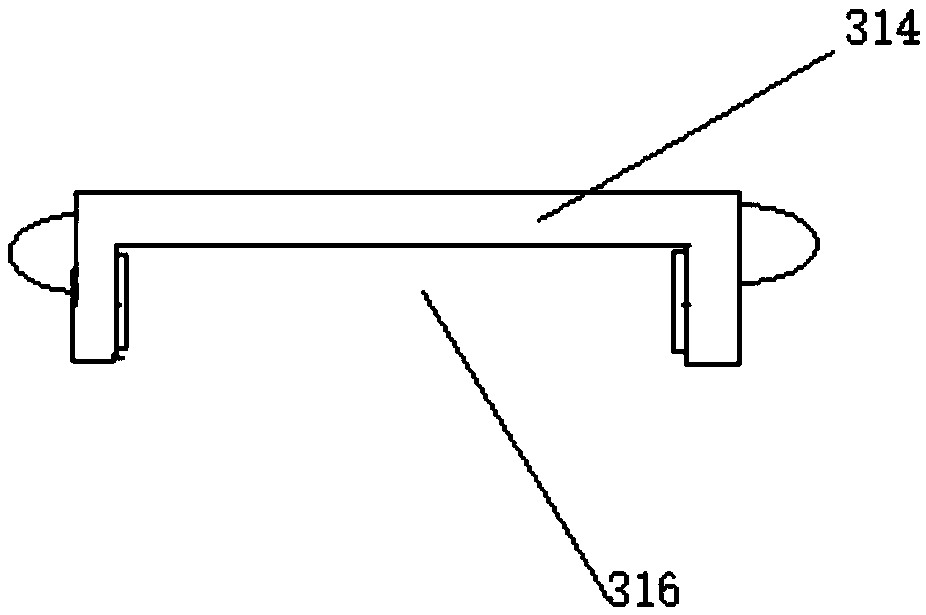

[0097] As shown in the figure, an efficient and intelligent bottle cap installation robot arm includes: a base 1, a first robot arm 2 for grabbing bottle caps, a second robot arm 3 for installing bottle caps, and a control device 4 , the base 1 is provided with a column 11, the first mechanical arm 2 and the second mechanical arm 3 are installed on the column 11, and a transmission is provided between the first mechanical arm 2 and the second mechanical arm 3 mechanism 5, and the first mechanical arm 1 and the second mechanical arm 3 cooperate with each other, the end of the first mechanical arm 2 is provided with an upper cap mechanism 21 for grabbing the bottle cap, and the second mechanical arm 3 A tightening mechanism 31 for tightening the bottle cap is provided on the upper cover mechanism 21. A bottle cap position detection mechanism 201 and a bottle mouth position detection mechanism 202 are arranged on the upper cap mechanism 21. A position for detecting the position of...

Embodiment 2

[0109] A kind of working method of efficient intelligent bottle cap installation mechanical arm described in this embodiment, the specific working method is as follows:

[0110] 1): First install the bottle cap installation robot arm according to the requirements, first install the column 11 on the base 1, then install the first robot arm 2 and the second robot arm 3 on the column 11, and feed the material The box 6 is installed on the column 11 and is located on one side of the first mechanical arm 2;

[0111] Then the bottle cap position detection mechanism 201, the bottle mouth position detection mechanism 202, the position detection mechanism 301, the bottle cap detection mechanism 7, the infrared sensor 621 and are installed to the designated position, and finally the electric control part on the installation mechanical arm is connected, Once connected, it can be put into use;

[0112] 2): Before putting into production, adjust the positions of the first mechanical arm 2...

Embodiment 3

[0130] As shown in the figure, an efficient and intelligent bottle cap installation robot arm includes: a base 1, a first robot arm 2 for grabbing bottle caps, a second robot arm 3 for installing bottle caps, and a control device 4 , the base 1 is provided with a column 11, the first mechanical arm 2 and the second mechanical arm 3 are installed on the column 11, and a transmission is provided between the first mechanical arm 2 and the second mechanical arm 3 mechanism 5, and the first mechanical arm 1 and the second mechanical arm 3 cooperate with each other, the end of the first mechanical arm 2 is provided with an upper cap mechanism 21 for grabbing the bottle cap, and the second mechanical arm 3 A tightening mechanism 31 for tightening the bottle cap is provided on the upper cover mechanism 21. A bottle cap position detection mechanism 201 and a bottle mouth position detection mechanism 202 are arranged on the upper cap mechanism 21. A position detection mechanism 301 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com