Loading and unloading operation area for container truck

A technology for container trucks and operating areas, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of low efficiency, slow loading and unloading, transshipment speed, low degree of automation, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation

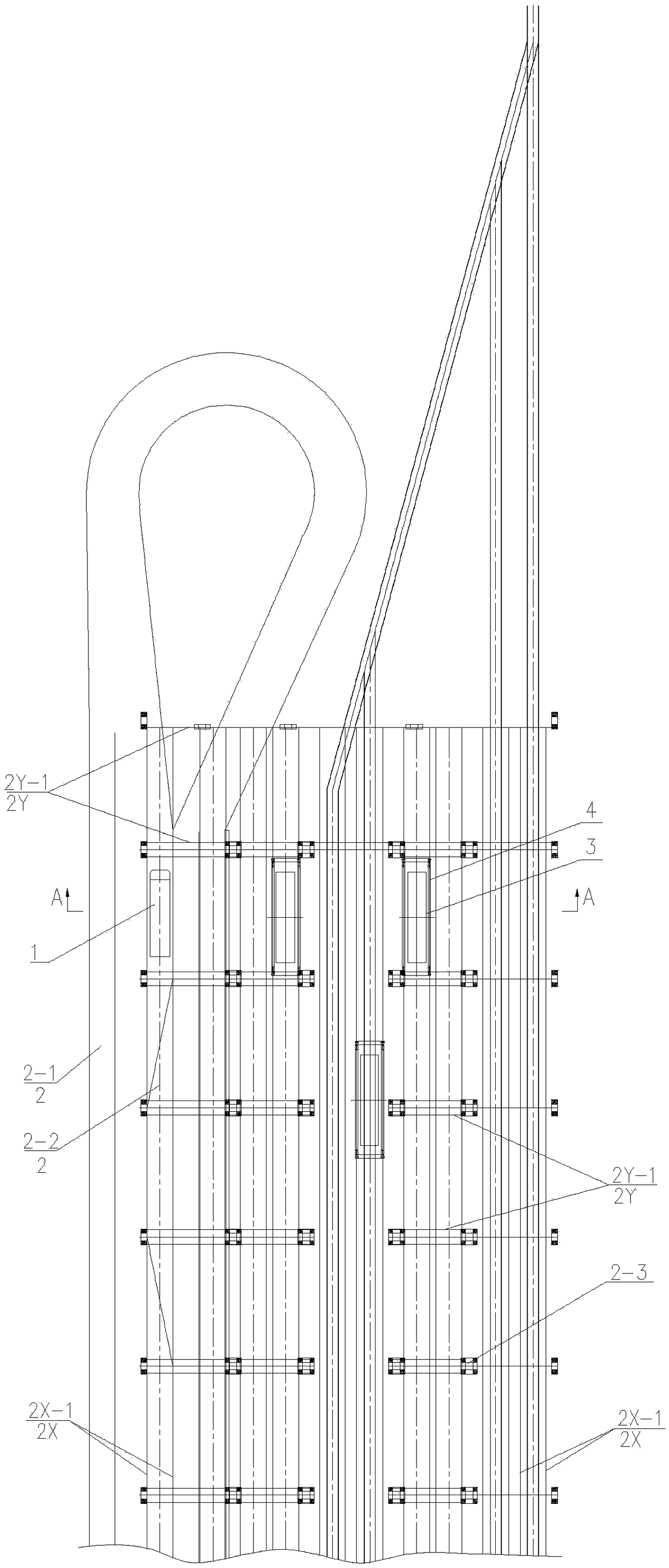

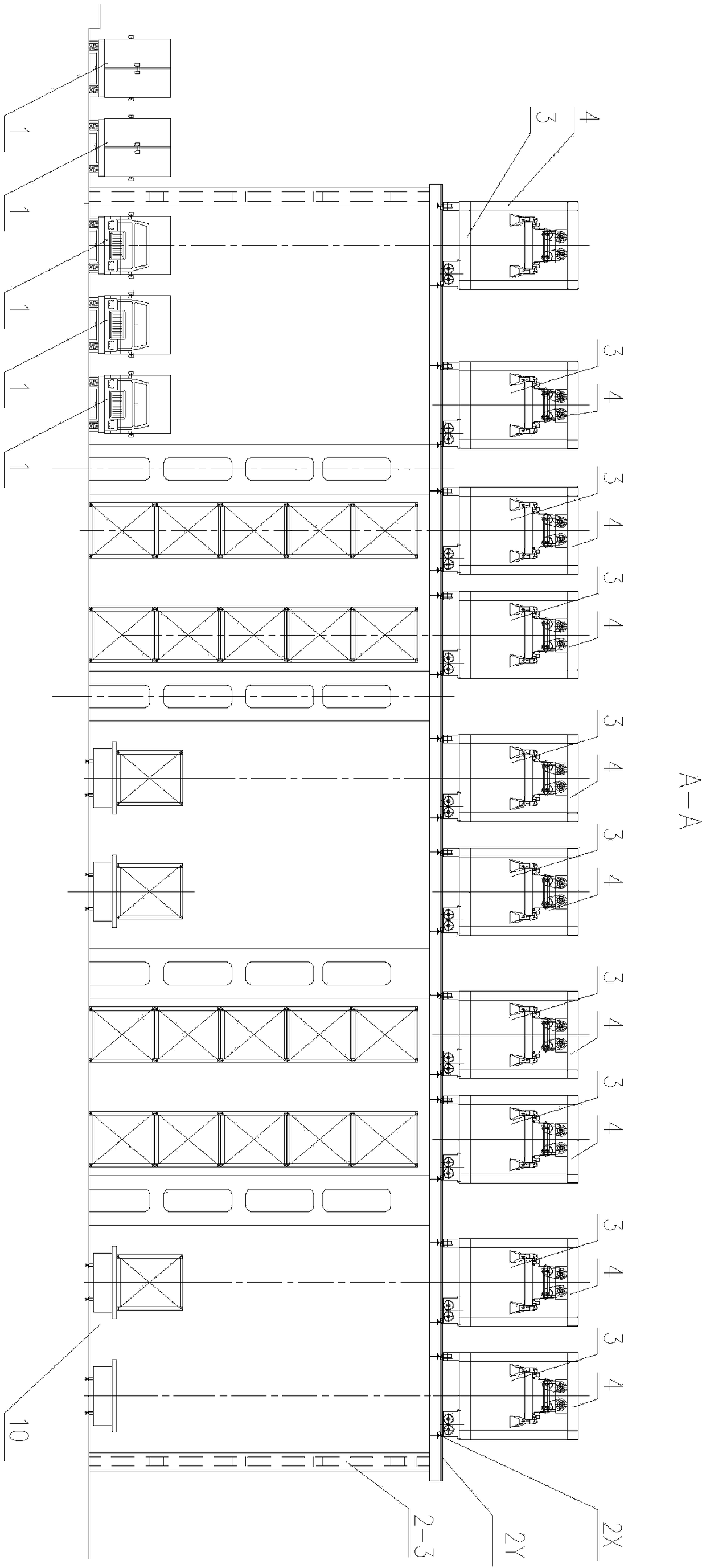

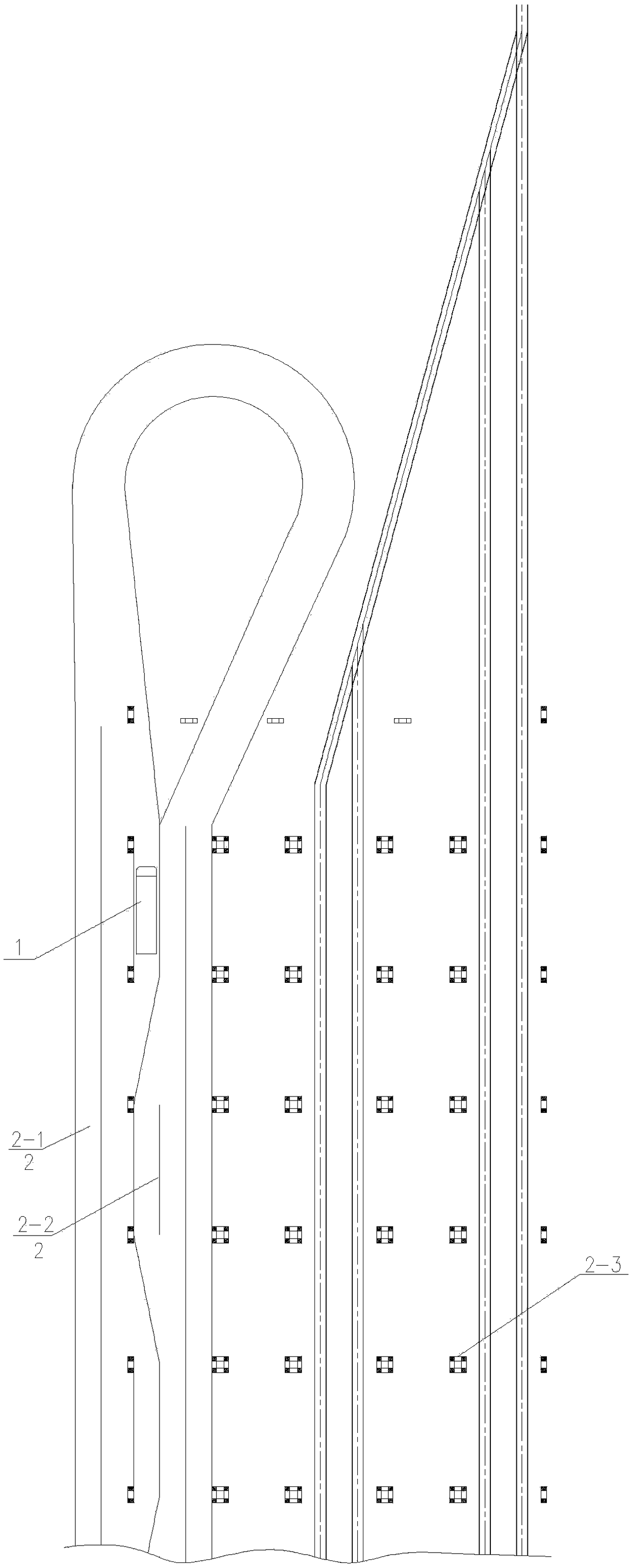

[0032]The loading and unloading operation area 2 used for the container truck 1 in the railway or wharf yard includes the conveying device 4 of the container 3, and the loading and unloading operation area 2 includes the lane 2-1, the loading and unloading parking space 2-2, the column member 2-3, the transverse rail 2X and The longitudinal track 2Y, the length direction of the lane 2-1 that the container truck 1 runs is the X direction, then the length direction of the transport vehicle 4 and the length direction of the container 3 are both the X direction, and the width direction of the transport vehicle 4 and the width direction of the container 3 It is the Y direction, several lanes 2-1 are arranged side by side in the Y direction, the loading and unloading parking spaces 2-2 are located in the lanes 2-1, the horizontal track 2X and the longitudinal track 2Y are aerial tracks fixed on the top of the column member 2-3, and the loading and unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com