Knurling and lettering integrated machine

An all-in-one machine and knurling technology, which is applied in stamping, decorative art, printing, etc., can solve the problems of low processing efficiency, easy to wear on the surface, and affect the appearance of the product, so as to improve processing efficiency, reduce scratches, and perfect appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

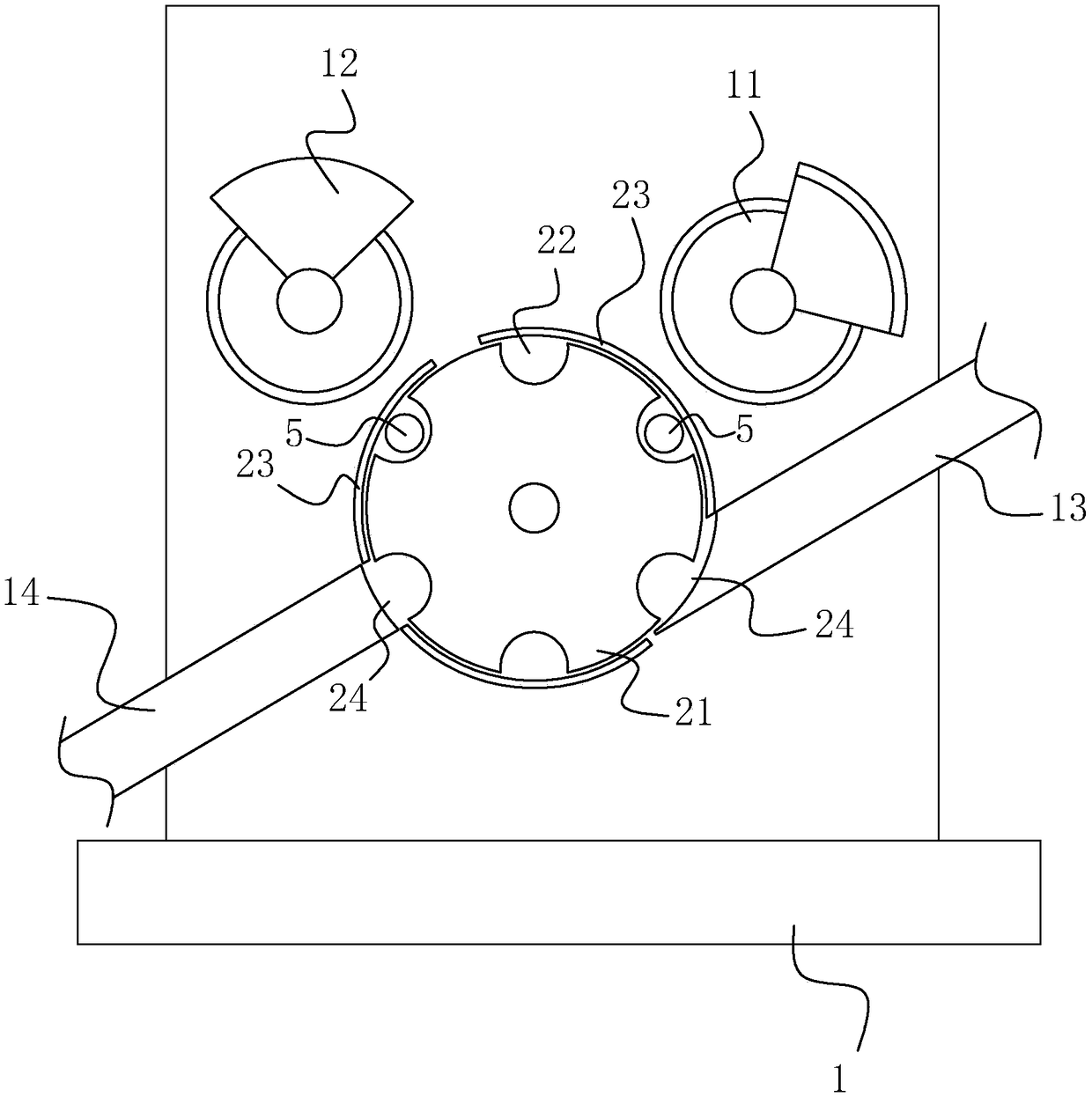

[0034] Embodiment: a kind of knurling embossing all-in-one machine, such as figure 1 As shown, the two sides of the fuselage 1 are respectively connected with a feed rail 13 and a discharge rail 14 . A knurling device 11 and an embossing device 12 are installed on the fuselage 1, the knurling device 11 is used for knurling the aluminum bottle cap, and the embossing device 12 is used for embossing the aluminum bottle cap. A transfer mechanism 2 for transferring aluminum bottle caps is installed on the body 1 close to the knurling device 11 and the embossing device 12, and the transfer mechanism 2 is used to transfer the aluminum bottle caps from the feed track 13 to the knurling device 11 and embossing device 12, make the aluminum bottle cap accept knurling and embossing, and then transport the aluminum bottle cap to the discharge track 14. The transfer mechanism 2 includes a turntable 21 and an ejection mechanism 3 . The turntable 21 is vertically arranged and rotatably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com