Valve needle and hot runner system with same

A technology of hot runners and valve pins, applied in the field of hot runners, can solve problems such as adhesion of injection molded products, affecting the processing yield of injection molded products, heating marks, etc., to achieve the effect of reducing heat capacity, reducing the possibility of adhesion, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

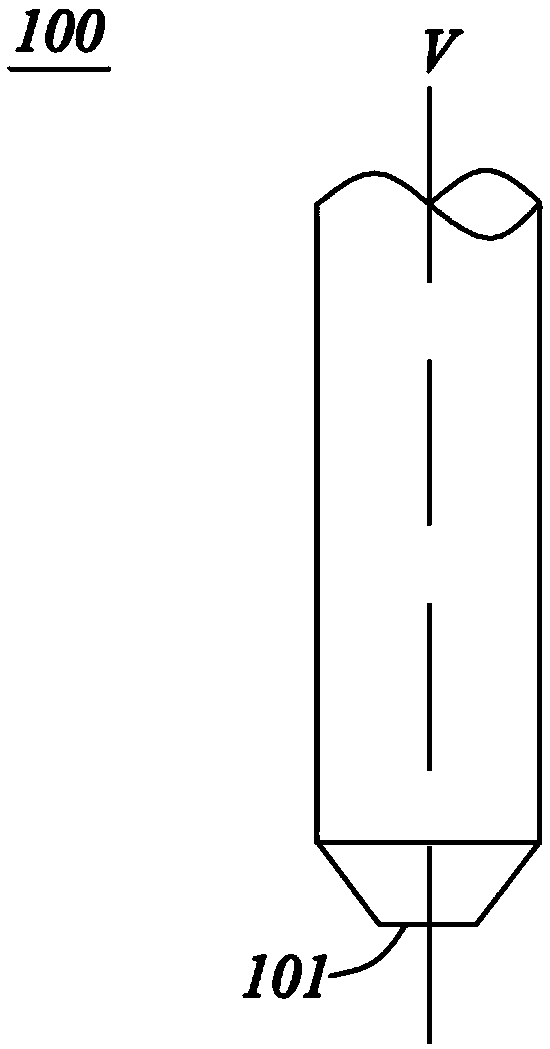

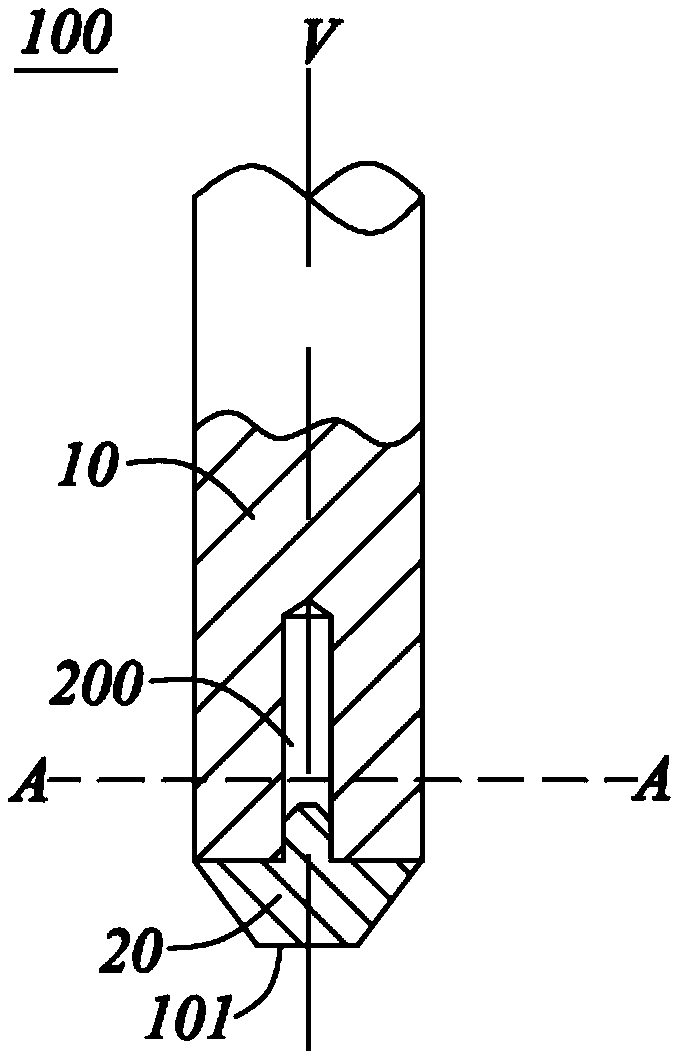

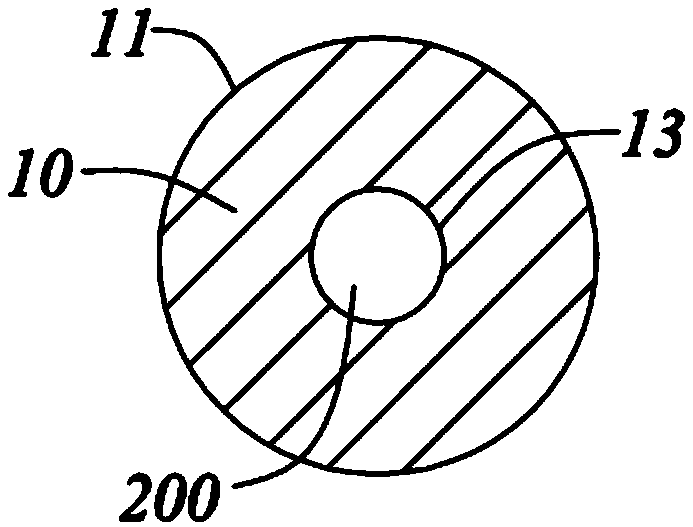

[0022] An embodiment of the present invention provides a hot runner system, which is applied in an injection mold. The hot runner system includes a driving device, a manifold, a hot nozzle, and a valve needle.

[0023] The hot nozzle is assembled under the splitter plate, and a hot runner for the molten glue to flow is formed in the splitter plate and the hot nozzle. Wherein, the hot runner includes a distribution channel formed in the splitter plate, the distribution channel has a glue inlet that is compatible with the injection molding machine nozzle, and at least one glue outlet; The delivery chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com