Pressing device of uncoiler

A pressing device and uncoiler technology, which is applied in the field of uncoiler pressing device, can solve the problems of small pressure test area, equipment wear, motor damage, etc., and achieve the goal of improving the pressure application effect, improving the friction effect, and increasing the pressure application area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

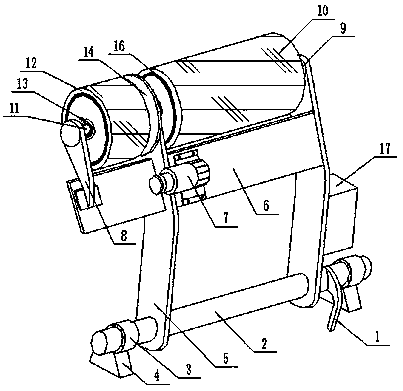

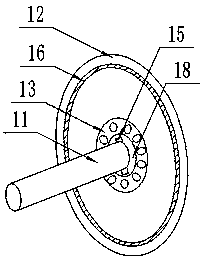

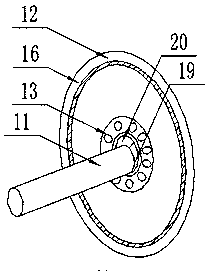

[0020] Such as Figure 1-Figure 3 As shown, the present invention provides a pressing device for an uncoiler, which includes a connecting rod 1 that is rotatably connected to the piston rod. The connecting rod 1 is fixedly connected to one side of the rotating shaft 2. Both ends of the rotating shaft 2 are located in the first bearing 3 for adjusting The height and pressing position of the pressing device, the bottom of the first bearing 3 is provided with a base 4, the two sides of the rotating shaft 2 are fixedly connected to the support plate 5 between the first bearing 3, and the support plate 5 is provided with a horizontal plate 6 and the horizontal plate One end of 6 runs through the support plate 5, and the horizontal plate 6 is provided with a motor 7 and an auxiliary support plate 8. The motor 7 is used to apply pressure to the auxiliary pressure roller 12 to increase the pressure effect of the auxiliary pressure roller 12. The top of the support plate 5 The main fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com