Root curved face sealing structure of deep-sea waterproof conduit female joint

A water-resistant conduit and sealing structure technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems that the sealing ring can only be used once, the right-angled edge is easy to damage the sealing ring, and the right-angled part is easy to form cracks, etc., to achieve Easy to release stress, easy to manufacture, and improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

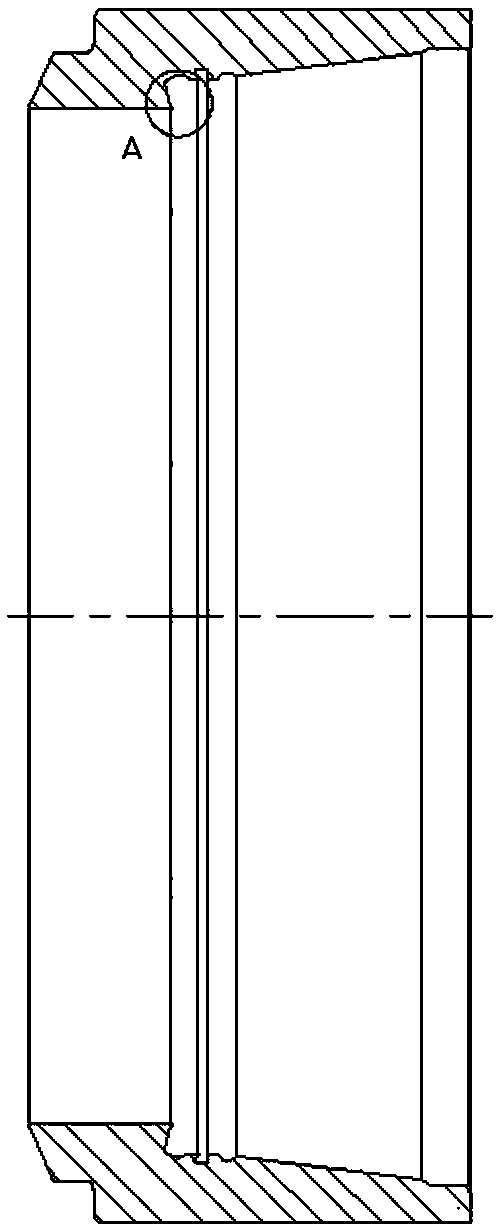

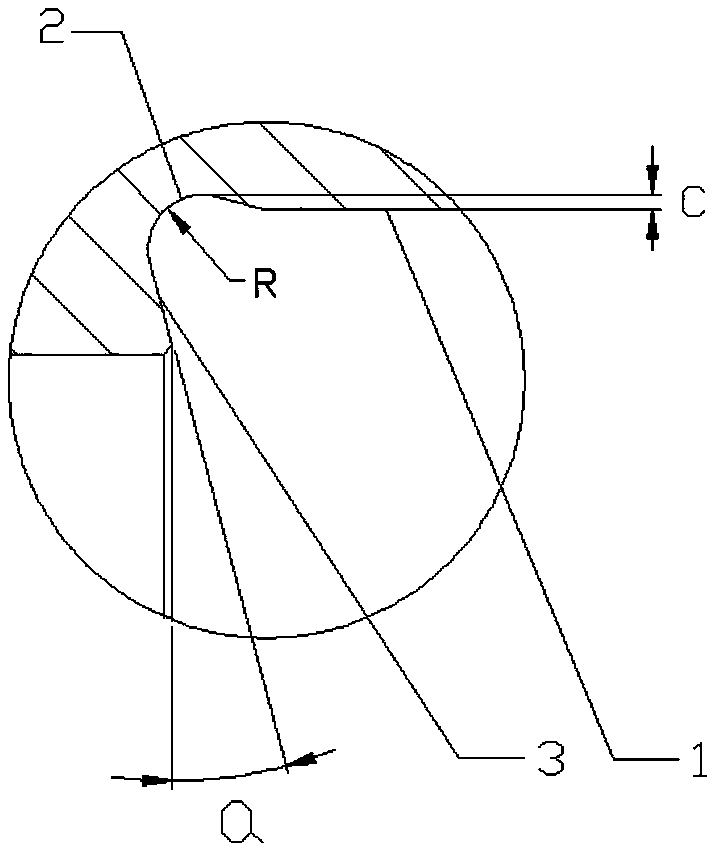

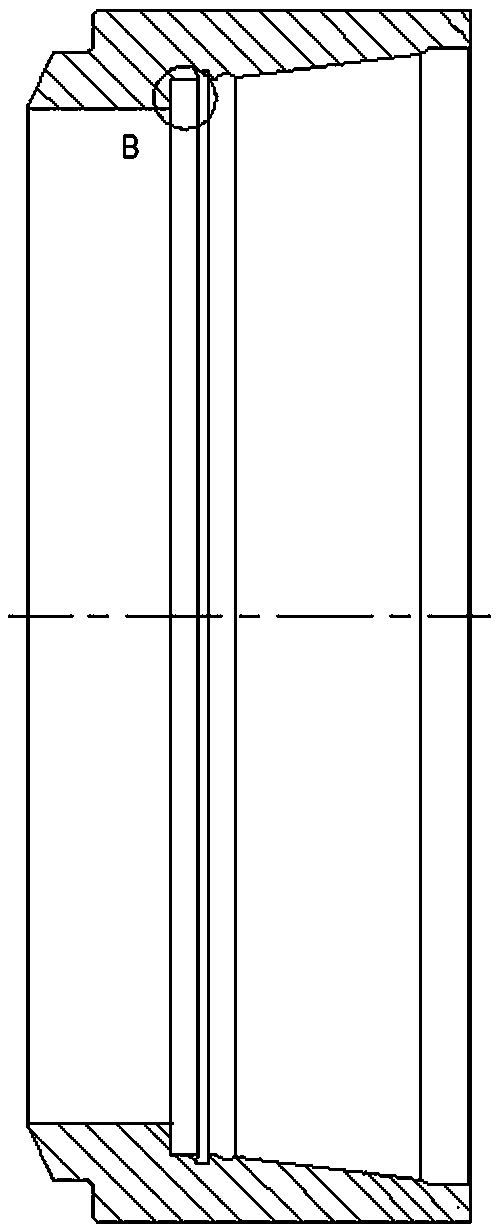

[0019] This embodiment is a curved surface sealing structure of a female joint of a deep-sea water riser with a diameter of 14 inches. The structure is located at the end of the internal thread of the female joint. The inclined end face 3 is the end face of the inner orifice, and in this embodiment, the end face is inclined outward by α=12° relative to the flat end face of the inner orifice. The inner wall 1 is the inner wall of a circular hole parallel to the axis. The inner wall 1 and the inclined end surface 3 are connected by an outwardly convex arc surface 2. In this embodiment, the curvature radius of the arc surface 2 is R=2.75, and the arc surface 2 Depth C=1mm into the inner wall 1. Through the combination of the above structural elements, the curved surface sealing structure of the female joint of the deep sea water riser is formed.

Embodiment 2

[0021] This embodiment is a curved surface sealing structure of a female joint of a deep-sea water riser with a diameter of 40 inches. The inclined end face 3 is the end face of the inner orifice, and in this embodiment, the end face is inclined outward by α=15° relative to the flat end face of the inner orifice. The inner wall 1 is the inner wall of a circular hole parallel to the axis. The inner wall 1 and the inclined end surface 3 are connected by an outwardly convex arc surface 2. In this embodiment, the radius of curvature of the arc surface 2 is R=3.5, and the arc surface 2 Depth C=2mm into the inner wall 1. Through the combination of the above structural elements, the curved surface sealing structure of the female joint of the deep sea water riser is formed.

[0022] In the present invention, the sealing structure at the root of the female joint of the deep-sea water-resisting conduit is designed as a curved surface, the purpose of which is to facilitate stress releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com