Preparation method for indium trisulfide@graphene oxide nanocomposite

A nanocomposite material, indium trisulfide technology, is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of reducing production costs, low energy consumption, and excellent synergistic catalysis effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

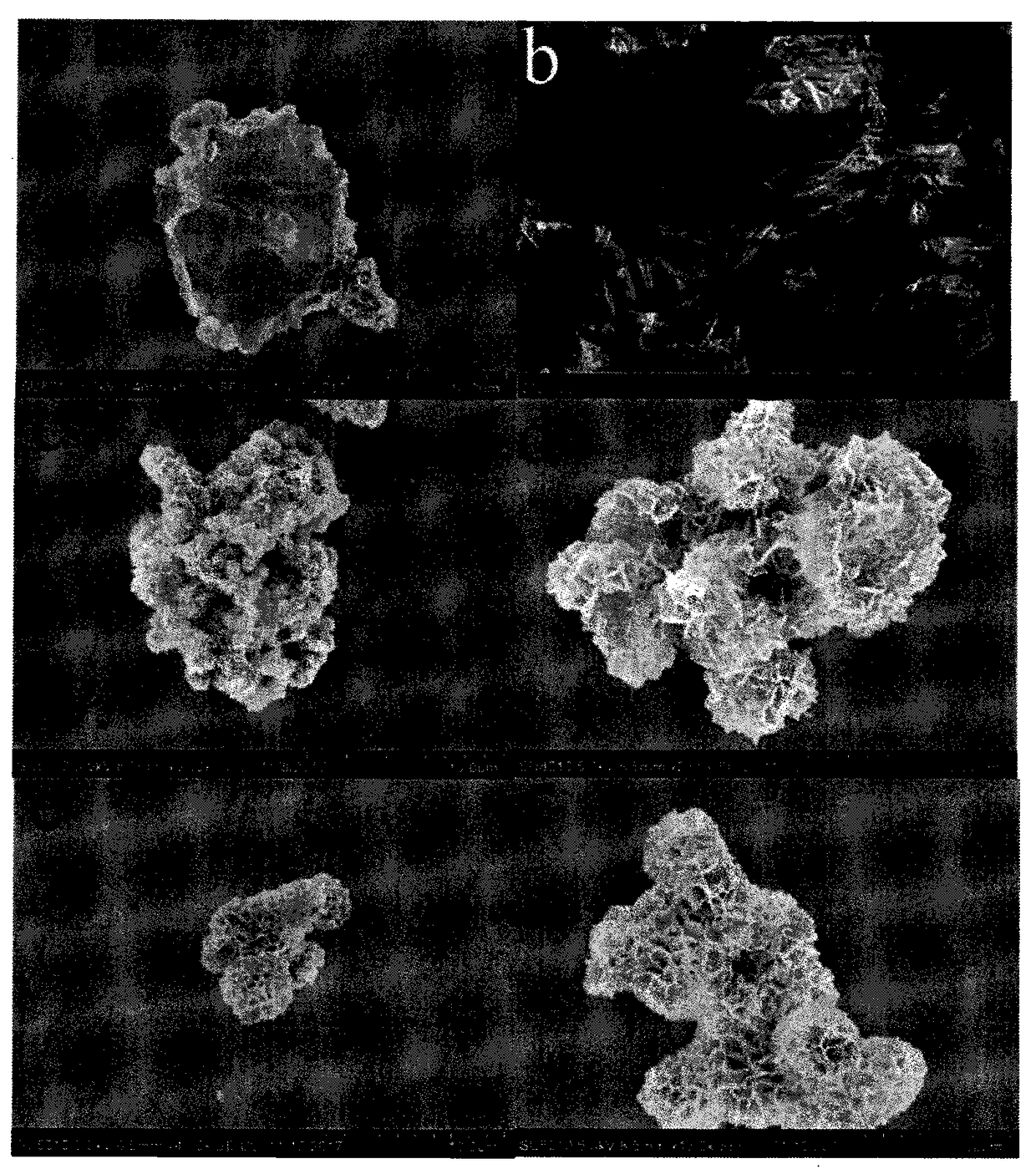

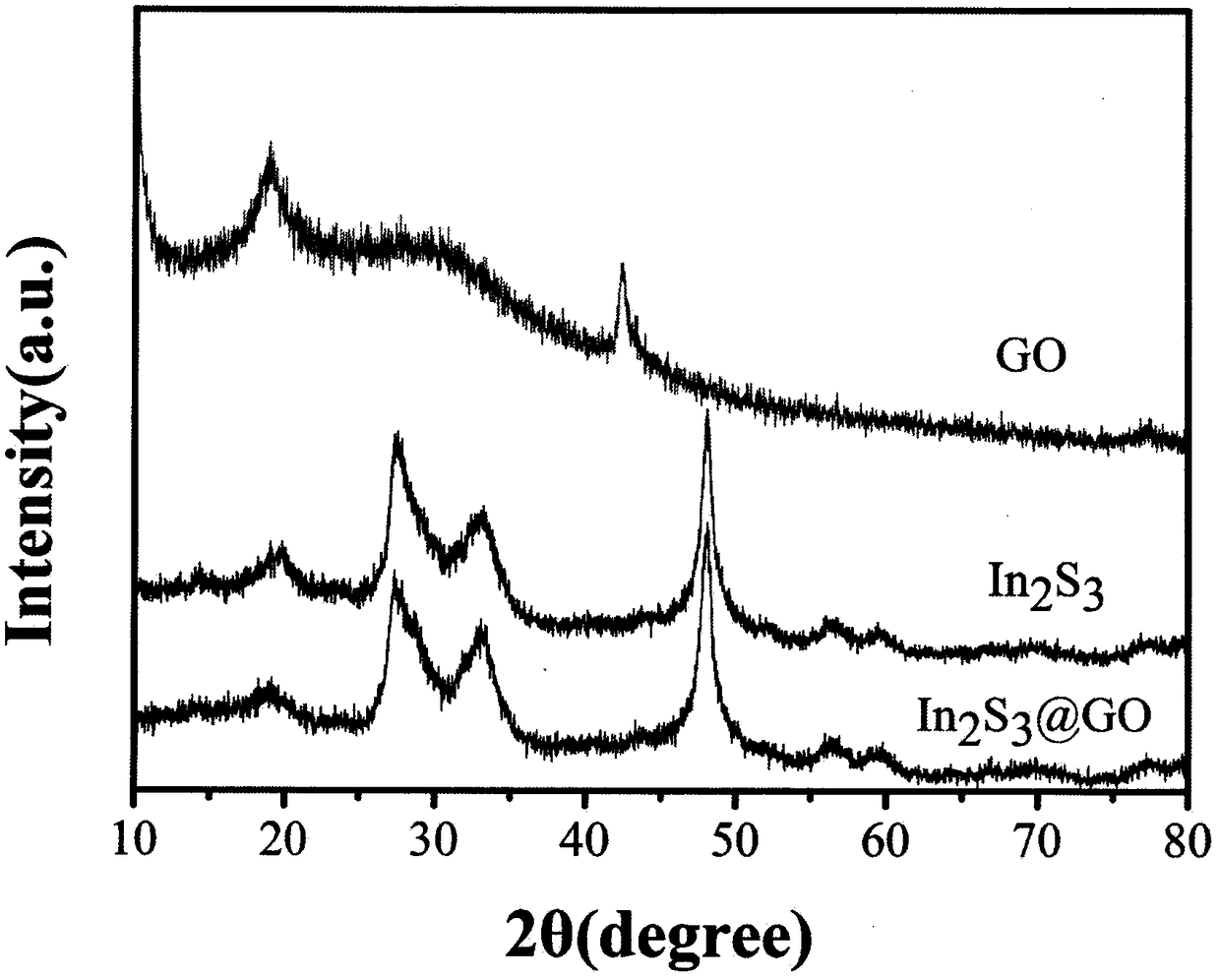

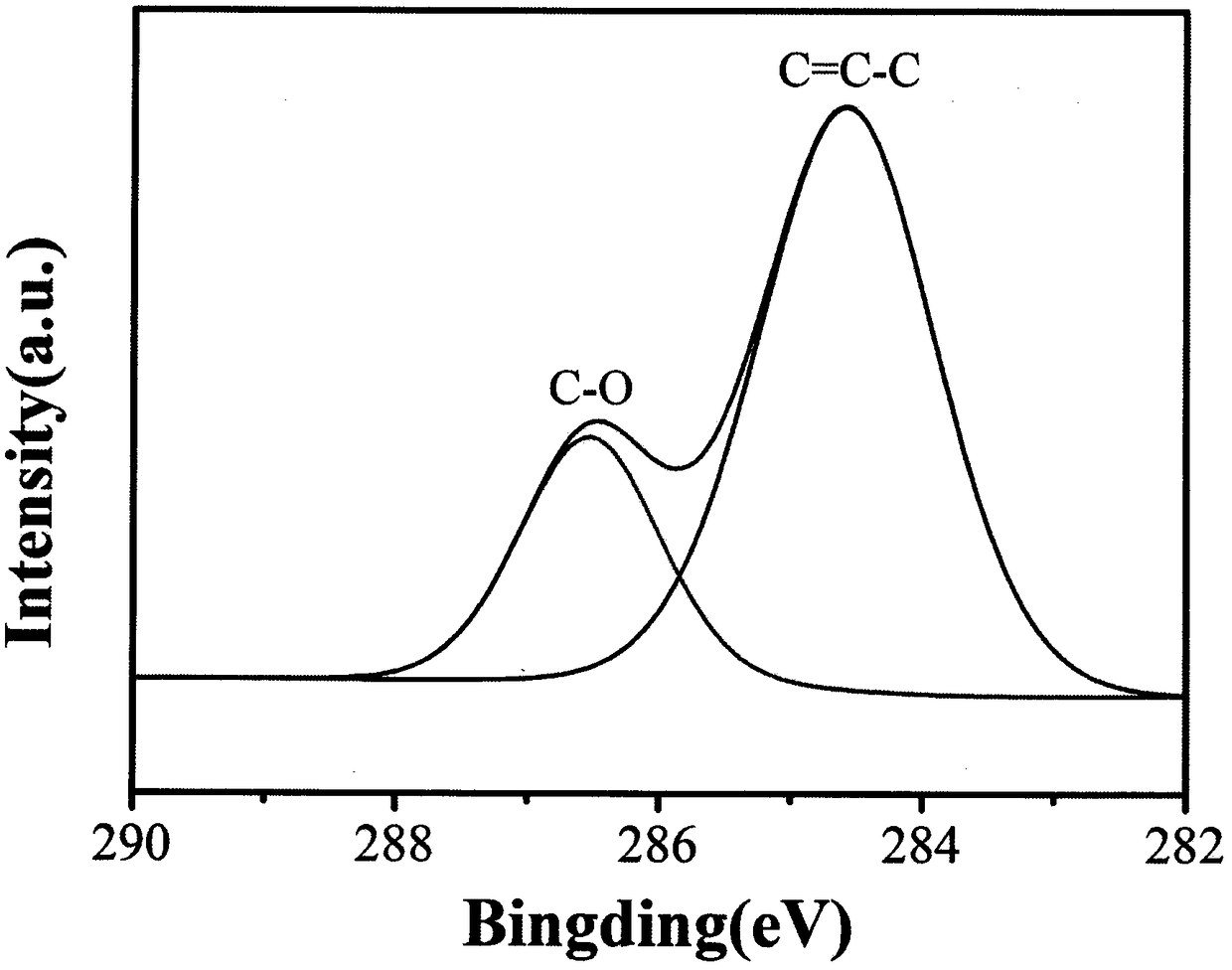

Image

Examples

Embodiment 1

[0023] Dissolve 1 gram of indium trisulfide in 1 liter of ethanol, add 10 milliliters of KH550, and stir for 11 hours to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 60 degrees Celsius for 2 hours at a vacuum degree of 0.09. Dissolve 0.05 g of graphene oxide in distilled water, add the solid obtained after sensitization, and stir for 12 hours to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 50°C for 2 hours.

Embodiment 2

[0025] Dissolve 1.2 g of indium trisulfide in 1 liter of ethanol, add 12 ml of KH550, and stir for 11 hours and 30 minutes to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 60 degrees Celsius for 2 hours at a vacuum degree of 0.09. Dissolve 0.07 g of graphene oxide in distilled water, add the solid obtained after sensitization, and stir for 12 hours to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 50°C for 2 hours.

Embodiment 3

[0027] Dissolve 1.4 g of indium trisulfide in 1 liter of ethanol, add 14 ml of KH550, and stir for 12 hours to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 60 degrees Celsius for 2 hours at a vacuum degree of 0.09. Dissolve graphene oxide in distilled water, add the solid obtained after sensitization, and stir for 12 hours to obtain a solid-liquid mixture. Wash twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn. The solid is taken out with ethanol and dried in vacuum at 50°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com