Sesame powdering device for brown sugar with three-stage linkage to form undirected trajectory

A powder spreading device and brown sugar technology, which is applied in the fields of confectionery, confectionery industry, food science, etc., can solve the problems affecting the appearance of the outsourcing powder of the brown sugar, powdering, more or less powdering, and sesame deterioration. To achieve the effect of easy utilization, lower production cost and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as Figure 1-2 As shown, the present invention provides a technical solution: a three-stage linkage forming a sesame powdering device for brown sugar with no direction track, including a working plate 1, and side plates 2 are fixedly connected to the left and right sides of the top of the working plate 1, The tops of the two side plates 2 are fixedly connected with a top plate 3, the center of the top of the top plate 3 is provided with a rotary pressing mechanism 4, the left side of the top of the working plate 1 is provided with a through groove 5, and the front and back of the inner wall of the through groove 5 are both movably connected. There is a rotating rod 6, and a U-shaped feeding plate 7 is fixedly connected between the two rotating rods 6. The material of the U-shaped feeding plate 7 is Q275 steel, the yield point is 275MPa, and the standard is GB / T700-2006. By setting U The U-shaped feeding plate 7 and the U-shaped feeding plate 7 can protect against f...

Embodiment 2

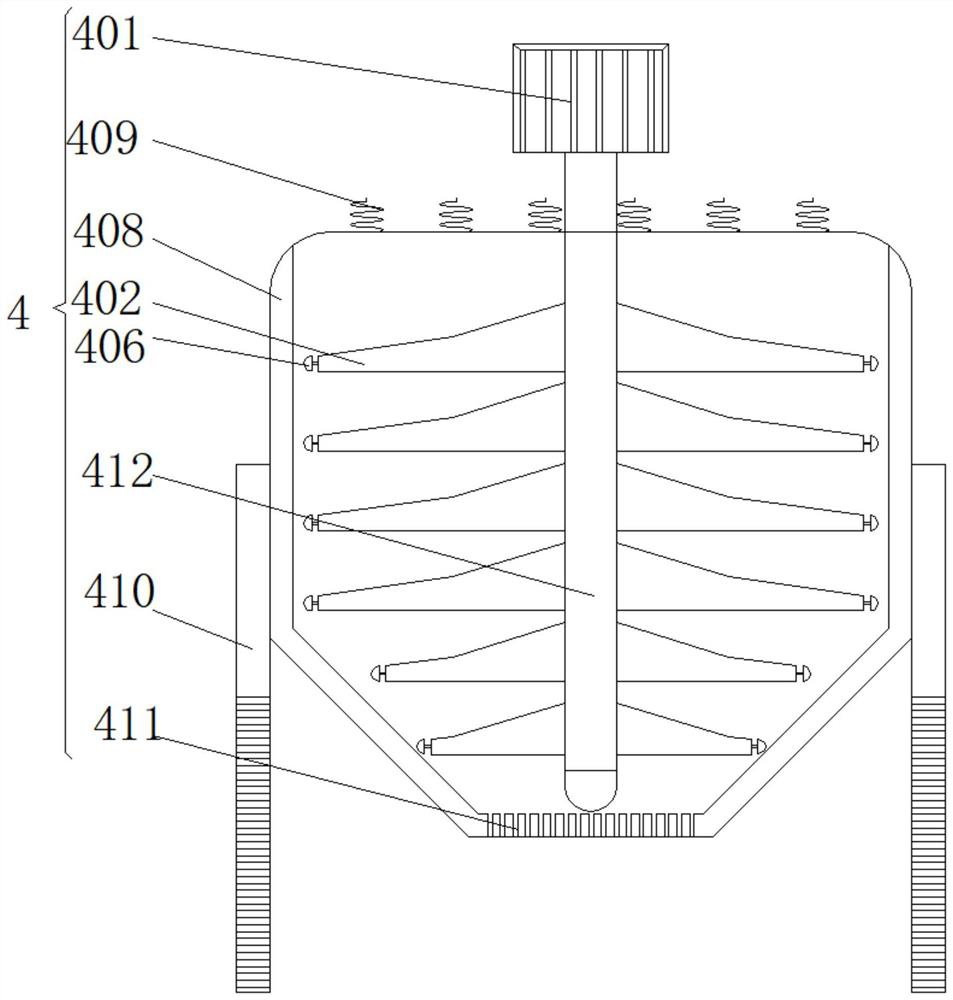

[0048] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the rotary pressing mechanism 4 includes a servo motor 401 and a drive cylinder 408 installed on the top plate 3, the bottom of the drive cylinder 408 is set in a conical shape, and drives The cross-sectional area of the bottom of the cylinder 408 is smaller than the cross-sectional area of the top of the driving cylinder 408. The bottom of the driving cylinder 408 is provided with a plurality of equally spaced material holes 411. The servo motor 401 is a Kollmorgen AKM waterproof motor with a static torque of 1-25N. -m, by adopting Kollmorgen AKM waterproof motor, hygienic and environmental protection, suitable for various fields, enhanced motor life, the output end of the bottom of the servo motor 401 passes through the top plate 3 and is fixedly connected with the rotating shaft E412, the left and right sides of the rotating shaft E412 The sides are fix...

Embodiment 3

[0050] Such as Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the rotary pressing mechanism 10 includes two rotating shafts C1001, and a U-shaped bar 1002 is fixedly connected between the two rotating shafts C1001, and is located on the left The rotating shaft C1001 on the side is fixedly connected with the rotating shaft A9, and the surface of the rotating shaft C1001 is fixedly connected with the sector gear A1003 through a flat key. A rolling rod 1004 is fixedly connected to the bottom of the rod 1002, and the rolling rod 1004 is located directly below the drive cylinder 408. A rolling protrusion 1005 is fixedly connected to the surface of the rolling rod 1004. By setting the rotating pressing mechanism 10, the rotating shaft C1001, U-shaped rod 1002, sector gear A1003, rolling rod 1004, rolling protrusion 1005, the biaxial motor 8 works to make the rotating shaft A9 rotate, and drive the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com