Main root cutoff mountainous region automatic tree mover

A tree digging machine and tap root cutting technology, which is applied in forestry, application, agriculture, etc., can solve the problems of difficulty in ensuring the quality of seedling soil balls, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

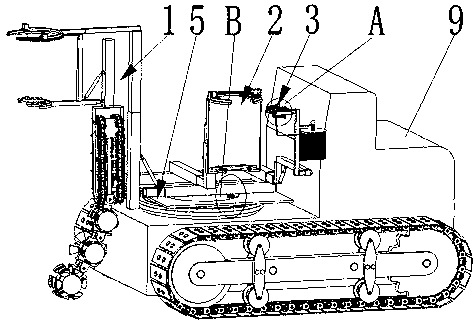

[0112] see figure 1 and Figure 4 As shown, the present invention is made up of tree digging device 1, hoisting and rotating soil ball device 2, rope winding device 3, turntable device 5, crawler vehicle 9 and gradient sensor, and crawler vehicle 9 is provided with chassis 91 and flange 92;

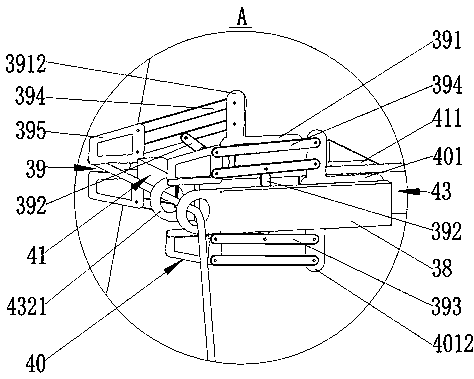

[0113] see Figure 4 and Figure 8 As shown, the tree digging device 1 is composed of a first telescopic assembly 11, a first luffing hydraulic cylinder 12, a second telescopic assembly 13, a cutter rotary motion drive assembly 14 and a combined cutter assembly 16, the first luffing hydraulic Oil cylinder 12 cylinder body is provided with double clevis 121, and piston rod is provided with single clevis 122;

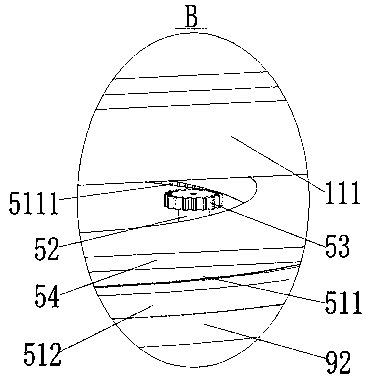

[0114] see Figure 8 As shown, the first telescopic assembly 11 is composed of a first stepped square cylindrical fixed arm 111, a first stepped square cylindrical telescopic arm 112, a first square cylindrical telescopic arm 113, a first multi-stage telescopic sleeve oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com