Automatic processing production line and production process of lead-acid batteries

A lead-acid battery and production line technology, applied in lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of time-consuming, labor-intensive, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

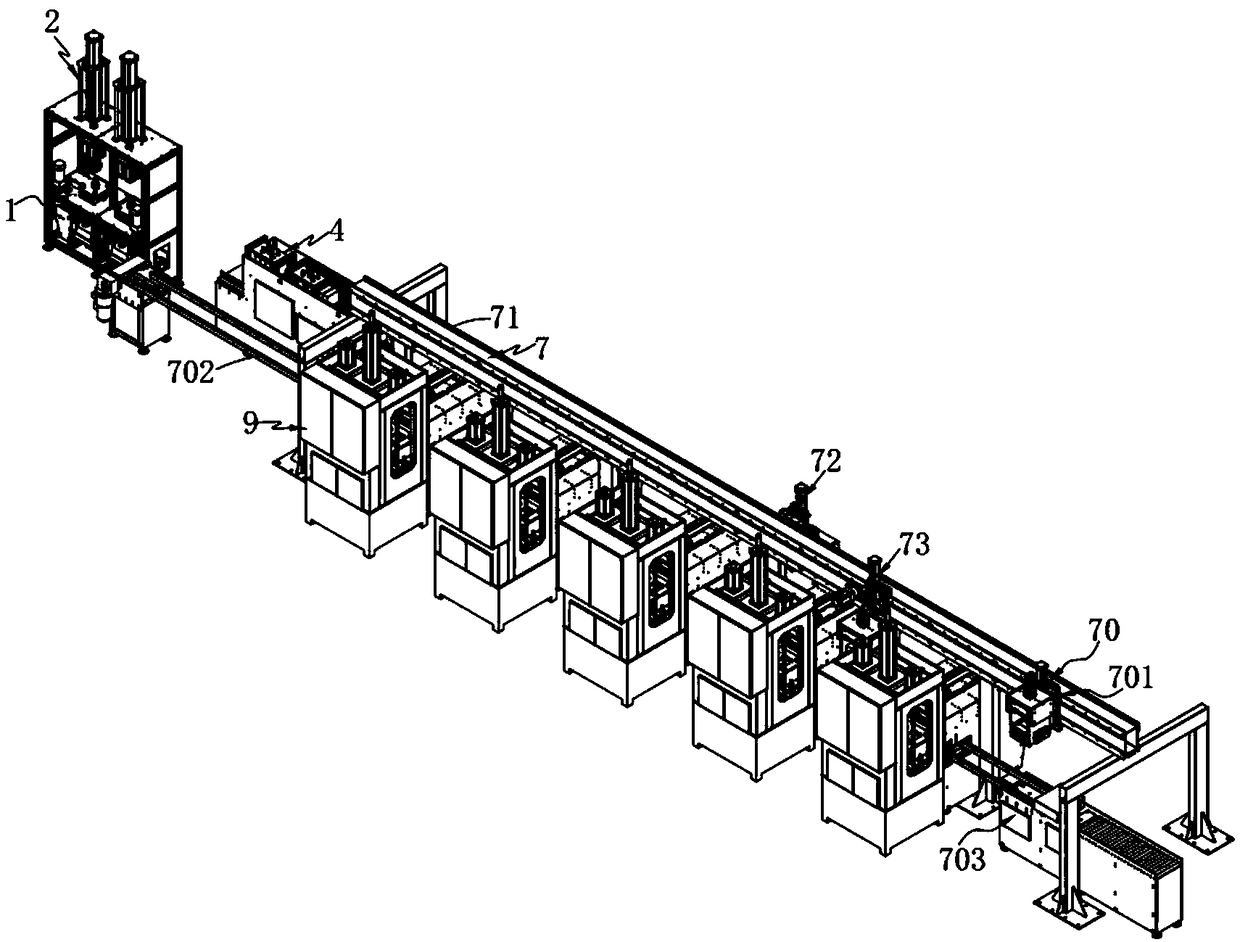

[0120] Such as figure 1 , figure 2 and Figure 4 As shown, a lead-acid battery automatic processing production line includes:

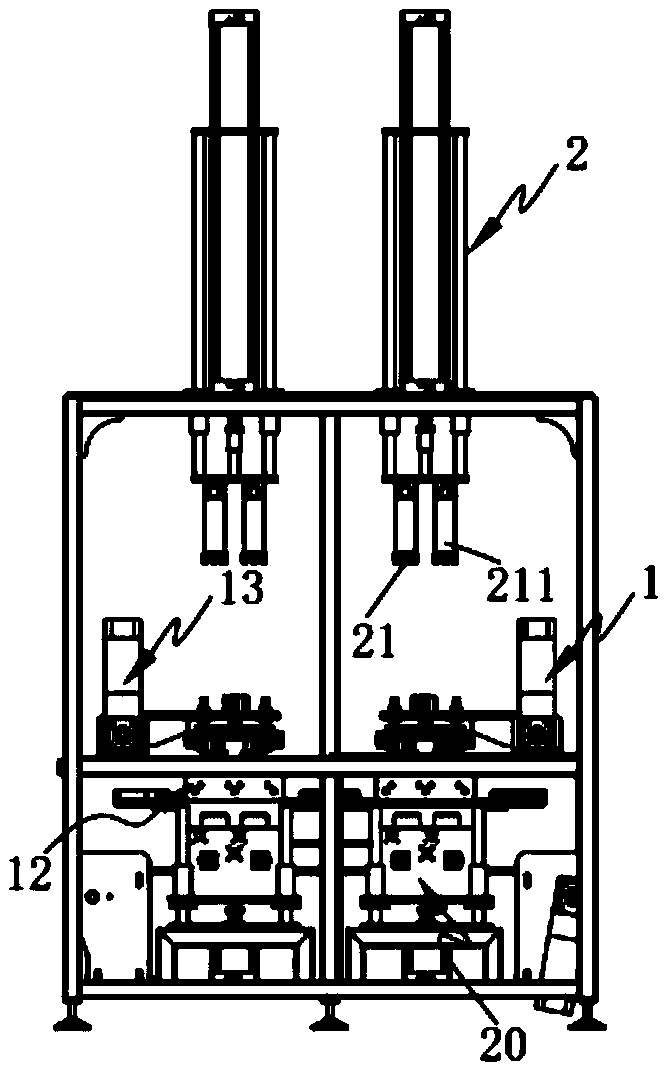

[0121] Extreme group shell-entry unit I, said extreme group shell-entry unit I includes:

[0122] Clamping device 1, described clamping device 1 comprises working platform 11 and the clamping mechanism 12 that is arranged on this working platform 11, and this clamping mechanism 12 is provided with several clamping areas 121, and in this clamping area 121 The pole group is clamped, and several plastic battery cases 10 are transported under the clamping mechanism 12;

[0123] The shell-entry device 2, the shell-entry device 2 is arranged on the top of the clamping device 1, it is pushed and set along the vertical direction, and its push end is provided with punching pins 21, and the punching pins 21 are evenly distributed with a number of Upright column 211, the upright column 211 is provided in one-to-one correspondence with the clamping area 121,...

Embodiment 2

[0195] Figure 24 It is a schematic structural view of Embodiment 2 of a lead-acid battery automatic processing production line of the present invention; Figure 24 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0196] Such as Figure 24 , Figure 25 and Figure 26As shown, a lead-acid battery automatic processing production line, the electrode group casing unit I also includes a plastic case feeding device 15 arranged at the front end of the clamping device 1, and the plastic case conveying group device 15 includes a longitudinal conveying assembly 151 and a Horizontal pushing assembly 152, vertical conveying assembly 151 is preferably a conveyor belt conveyor, b...

Embodiment 3

[0199] Figure 27 and Figure 28 It is a schematic structural view of Embodiment 2 of a lead-acid battery automatic processing production line of the present invention; Figure 11 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

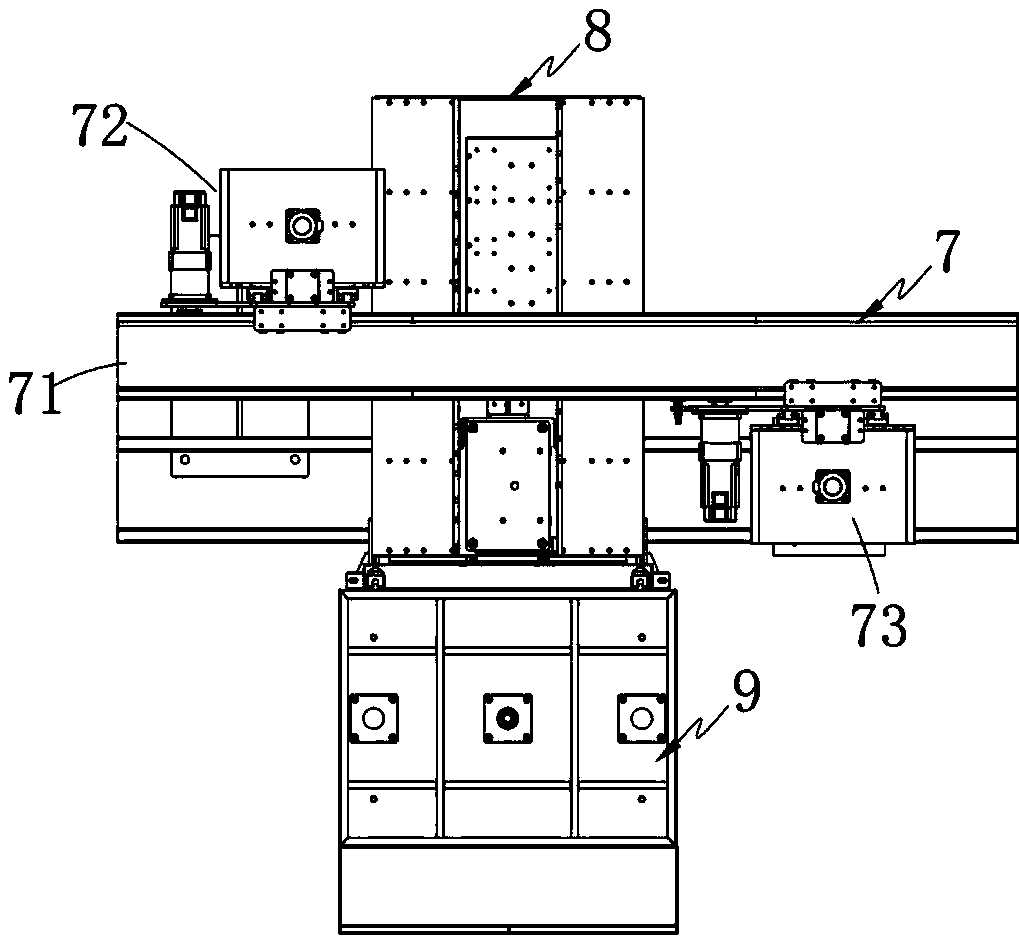

[0200] Such as figure 1 , Figure 27 and Figure 28 As shown, a lead-acid battery automatic processing production line, the casting and welding unit III also includes a recycling mechanism 70, and the recycling mechanism 70 includes:

[0201] The third fixture 701, the third fixture 701 and the second fixture 73 are arranged on the same side of the transverse rail 71, which is located at the rear side of the second fixture 73;

[0202]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com