A display panel and binding method

A technology of display panel and binding area, applied in the directions of printed circuit, printed circuit manufacturing, electric solid device, etc., can solve the problems of affecting the process, adhesion, unfavorable peeling, etc., to improve corrosion resistance, improve pressing accuracy, avoid The effect of line corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

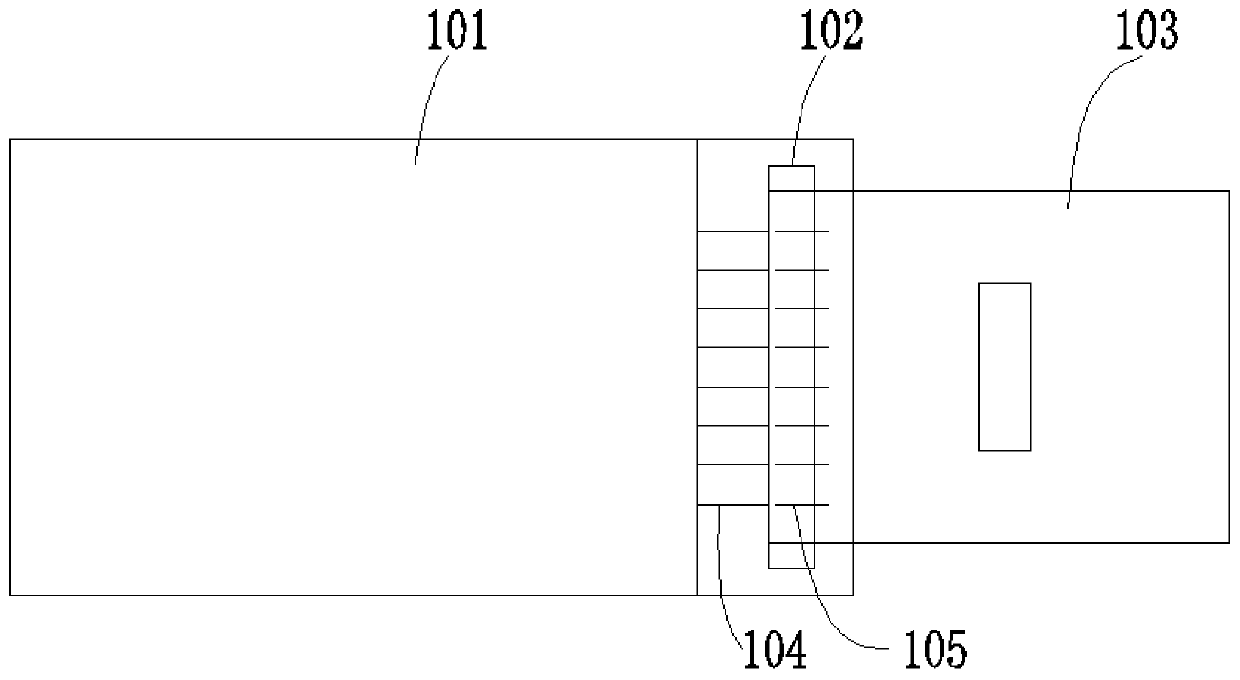

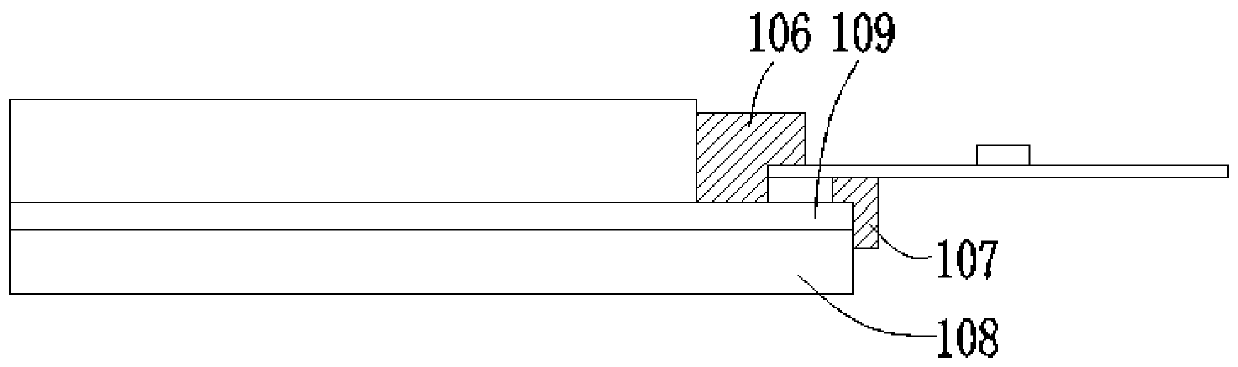

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present invention.

[0033] The present invention is aimed at the display panel of the prior art, because the back waterproof glue coated on the back bound to the signal wiring of the flexible circuit board and the display panel is adhered to the glass substrate, which is not conducive to peeling off, and the back waterproof glue after the glass substrate is peeled off The height exceeds the OLED layer and affects the technical problem of the subsequent manufacturing process. This embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com