Diode chip structure for inhibiting secondary snow slide

A chip structure and diode technology, applied in the field of diodes, can solve problems such as burning out diode chips, and achieve the effects of reducing failure rate, prolonging service life, and avoiding secondary avalanches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

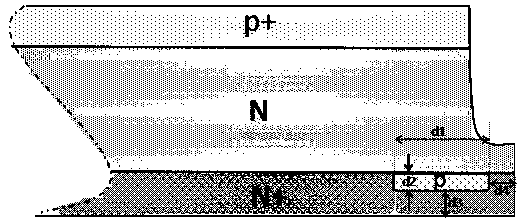

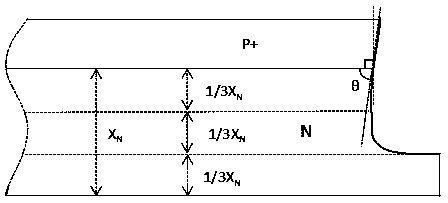

[0017] A diode chip structure for suppressing secondary avalanche, such as figure 1 , figure 2 As shown, it includes the anode P+ region, substrate N region and cathode N+ region distributed in sequence, and arc-shaped grooves are provided at the edge of the anode P+ region to two-thirds of the substrate N region, so that the edge PN junction forms an 80° ~90° positive slope angle, such as figure 2 As shown; the cathode N+ area is provided with a P-type control area.

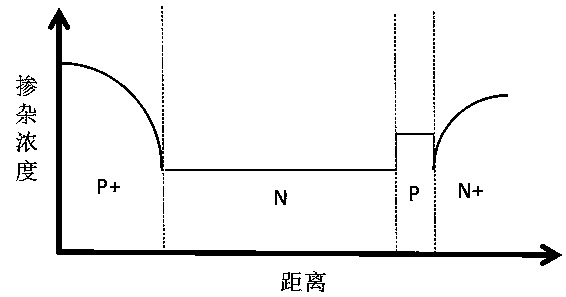

[0018] The average doping concentration of the P-type control region is 1e15-1e16cm -3 , greater than the average doping concentration of the N region of the substrate, and smaller than the average doping concentration of the anode P+ region. image 3 is the doping concentration distribution including the P-type control region.

[0019] The length d1 of the P-type control region is 1-10 μm, the thickness d2 is 0.5-50 μm, the distance d3 from the surface of the cathode N+ region is 20-90 μm, and the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com