Spherical nickel cobalt oxide-ceric oxide composite electrode material with multi-stage structure and preparation method thereof

A ceria and composite electrode technology, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. Supercapacitor energy storage devices, poor electronic conductivity and other problems, to achieve the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

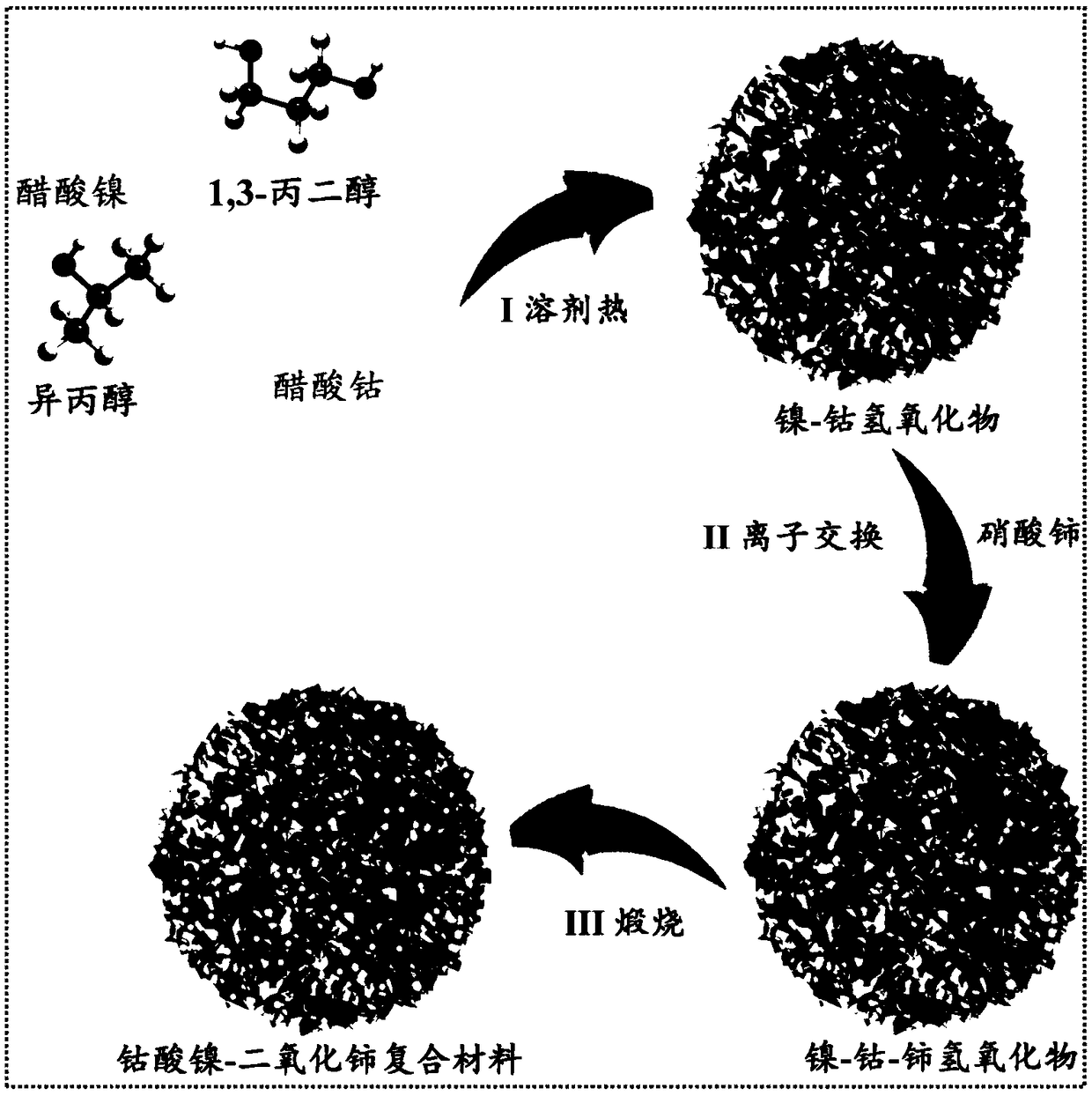

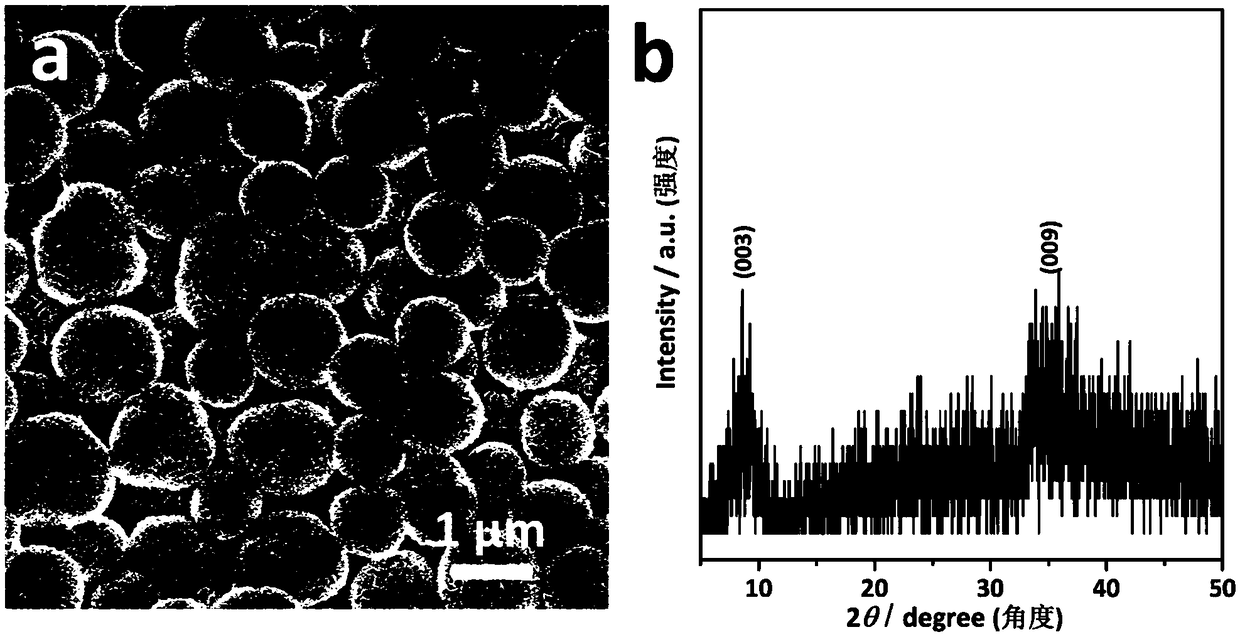

[0021] ① Add 0.50mmol nickel acetate tetrahydrate and 1.0mmol cobalt acetate tetrahydrate to a mixed solvent of 10mL 1,3-propanediol and 40mL isopropanol, stir to dissolve and mix well, then transfer the above reaction solution to a reaction kettle, and heat at 160°C Under the condition of solvothermal reaction for 12 hours, after the reaction was completed, naturally cooled to room temperature, the product was centrifuged, washed several times with absolute ethanol and dried to obtain spherical nickel-cobalt hydroxide with hierarchical structure.

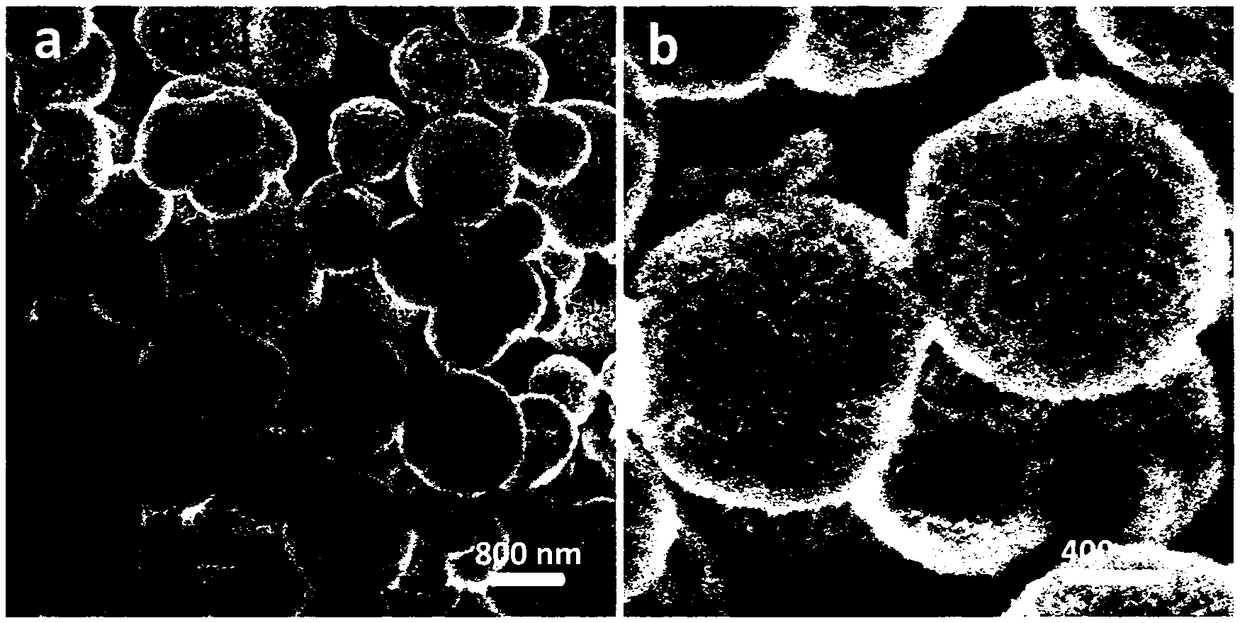

[0022] ②Add 0.0500g of cerium nitrate hexahydrate and 0.1g of spherical nickel-cobalt hydroxide with multi-level structure to 20mL of absolute ethanol. Reacted for 8 hours. After the reaction was completed, it was naturally cooled to room temperature, and the product was centrifuged, washed several times with absolute ethanol and dried to obtain nickel-cobalt-cerium hydroxide. The nickel-cobalt-cerium hydroxide is calcined at 300° ...

Embodiment 2

[0025] ① Add 0.25mmol nickel acetate tetrahydrate and 0.50mmol cobalt acetate tetrahydrate to a mixed solvent of 10mL 1,3-propanediol and 40mL isopropanol, stir to dissolve and mix well, then transfer the above reaction solution to a reaction kettle, and heat it at 160°C Under the condition of solvothermal reaction for 12 hours, after the reaction was completed, naturally cooled to room temperature, the product was centrifuged, washed several times with absolute ethanol and dried to obtain spherical nickel-cobalt hydroxide with hierarchical structure.

[0026] ②Add 0.0250g of cerium nitrate hexahydrate and 0.0500g of spherical nickel-cobalt hydroxide with multi-level structure to 20mL of absolute ethanol. Reacted for 8 hours. After the reaction was completed, it was naturally cooled to room temperature, and the product was centrifuged, washed several times with absolute ethanol and dried to obtain nickel-cobalt-cerium hydroxide. The nickel-cobalt-cerium hydroxide is calcined a...

Embodiment 3

[0028] ① Add 0.750mmol nickel acetate tetrahydrate and 1.50mmol cobalt acetate tetrahydrate to a mixed solvent of 20mL 1,3-propanediol and 30mL isopropanol, stir to dissolve and mix well, transfer the above reaction solution to a reaction kettle, Under the condition of solvothermal reaction for 12 hours, after the reaction was completed, naturally cooled to room temperature, the product was centrifuged, washed several times with absolute ethanol and dried to obtain spherical nickel-cobalt hydroxide with hierarchical structure.

[0029] ② Add 0.0750g of cerium nitrate hexahydrate and 0.1500g of spherical nickel-cobalt hydroxide with multi-level structure to 20mL of absolute ethanol. Reacted for 8 hours. After the reaction was completed, it was naturally cooled to room temperature, and the product was centrifuged, washed several times with absolute ethanol and dried to obtain nickel-cobalt-cerium hydroxide. The nickel-cobalt-cerium hydroxide is calcined at a high temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com