Method for evaluating microcrack width through nonlinear frequency mixing sound waves

A micro-crack, nonlinear technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, processing of detected response signals, instruments, etc., can solve problems such as parameters that cannot be effectively evaluated for cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

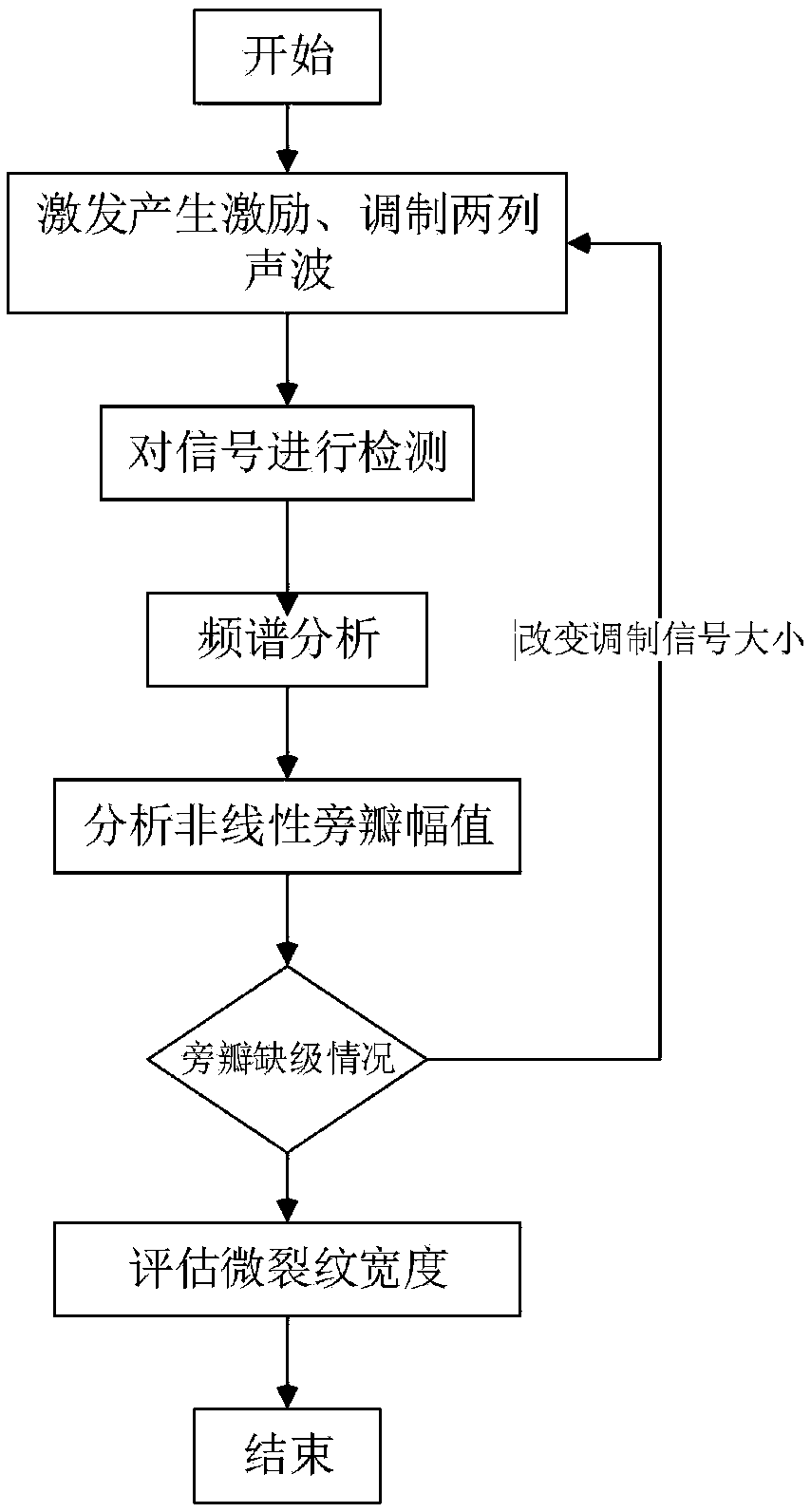

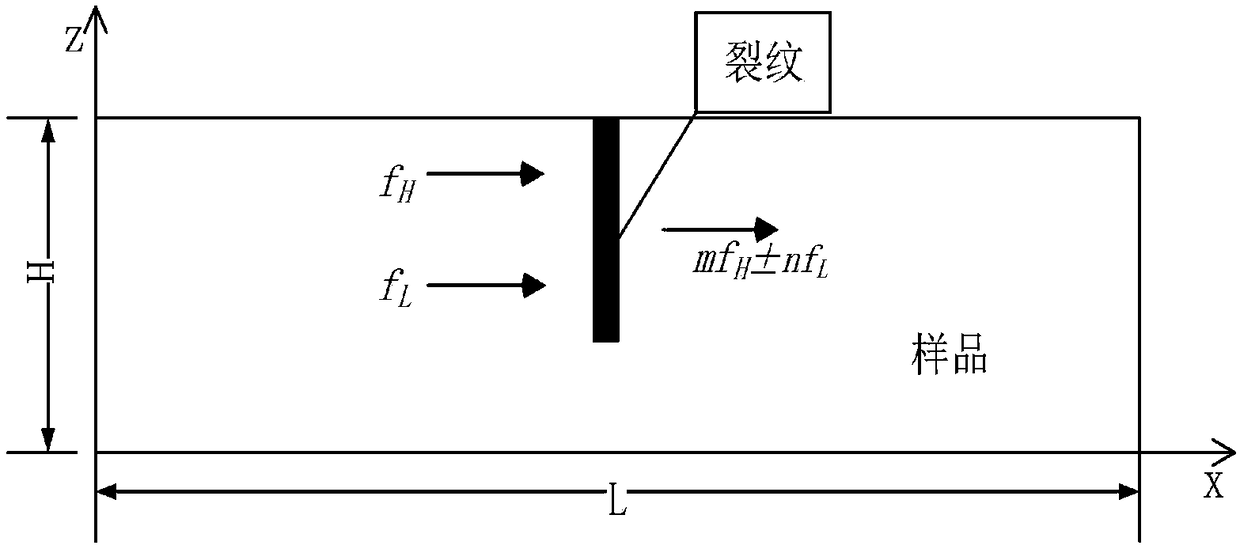

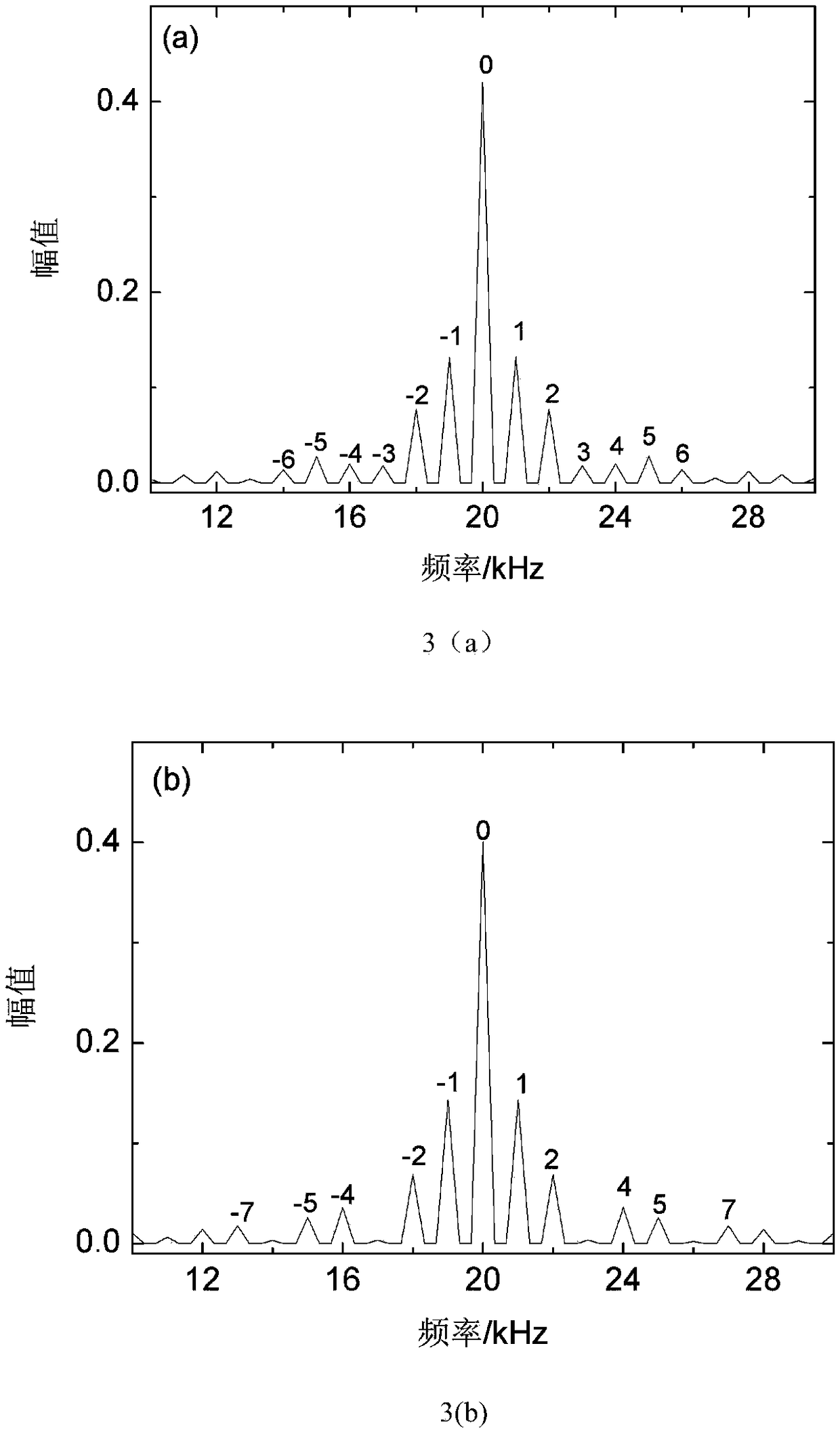

[0018] Such as figure 1 As shown, the method for evaluating the width of microcracks by nonlinear mixed-frequency acoustic waves includes the following steps:

[0019] Step 1. Excite two columns of sound waves with different frequencies, which are respectively used as an excitation signal (detection signal) and a modulation signal.

[0020] It is generally required that the modulation signal is a low-frequency sound wave, and the frequency is the natural frequency of the structure. Its size varies with the structure, generally tens to several thousand Hz, and the frequency used in this manual is 1kHz; the detection signal is a high-frequency sound wave, and the frequency is much greater than Modulation frequency, in numerical analysis, it is generally advisable to take 20 to 50 times (the frequency multiplication of the modula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com