An Adaptive Material Width Determining Device for Progressive Die

A determination device and self-adaptive technology, applied in the direction of feeding device, positioning device, storage device, etc., to achieve the effect of uniform force, fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

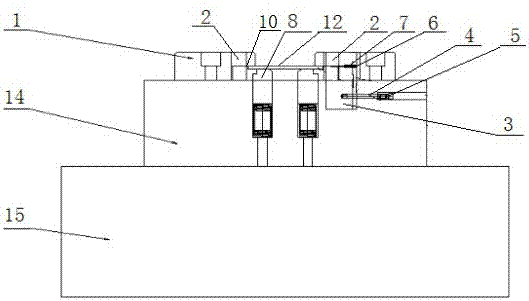

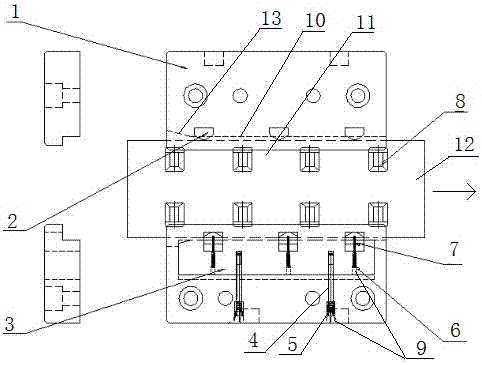

[0012] Such as figure 1 , figure 2 As shown, the self-adaptive material width determining device for the progressive die includes a material guide plate 1 which is arranged on the concave die plate 14 to form a material guide channel 11, a material guide plate 1 which is arranged on one side of the material guide channel 11, and A side edge stopper 3 that can move back and forth on the concave template 14, the concave template 14 is arranged on the lower mold base 15, the feed end of the guide channel 11 is provided with a bell mouth 13, and the side edge stopper 3 passes through The spring 5 and the screw 4 are connected with the concave template 14, and the spring 5 and the screw 4 are fixed with a plugging wire 9; side edges 2 are arranged on both sides of the material guide channel, wherein the side edge 2 on one side of the material guide channel 11 It is fixed on the material guide plate 1, and the side edge 2 on the other side is set on the side edge stopper 3 so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com