Honeycomb material production detecting method and equipment

A technology of honeycomb material and production inspection, applied in the field of composite material manufacturing, can solve the problem of difficult to precisely control the honeycomb structure, and achieve the effect of improving production inspection efficiency, reducing production cost and saving inspection process.

Pending Publication Date: 2018-11-13

SHENZHEN CANSINGA TECH CO LTD

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a honeycomb material production detection method and equipment to solve the technical problems in the prior art that the honeycomb material needs to be stretched multiple times due to the rebound phenomenon of the material in the production process of the honeycomb material, and the honeycomb structure is difficult to accurately control.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

[0047] Further, as a specific implementation of the honeycomb material production detection method provided by the present invention, the honeycomb material production detection method also includes the following steps:

[0048] S06. Calculate the mechanical parameters of the honeycomb material according to the above tension data and the above geometric data.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

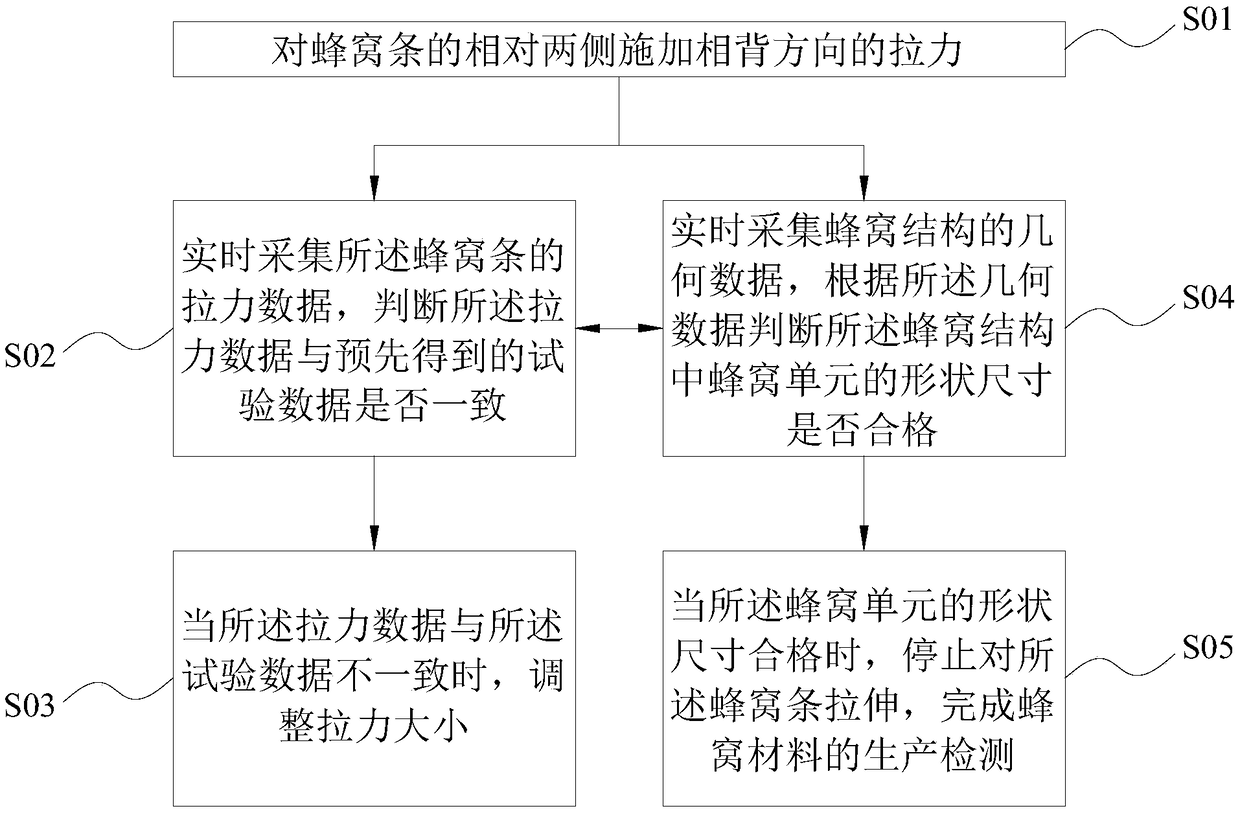

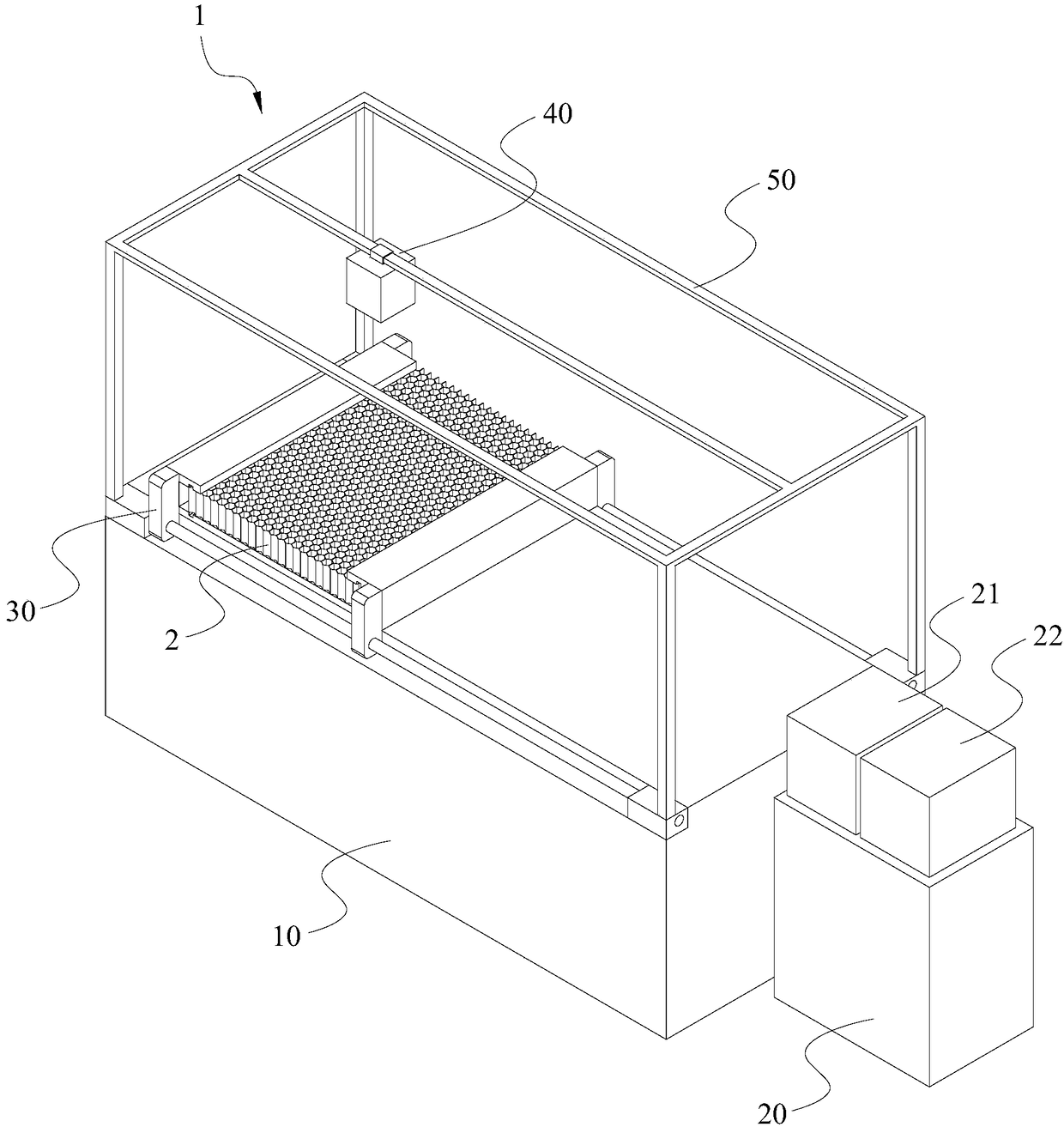

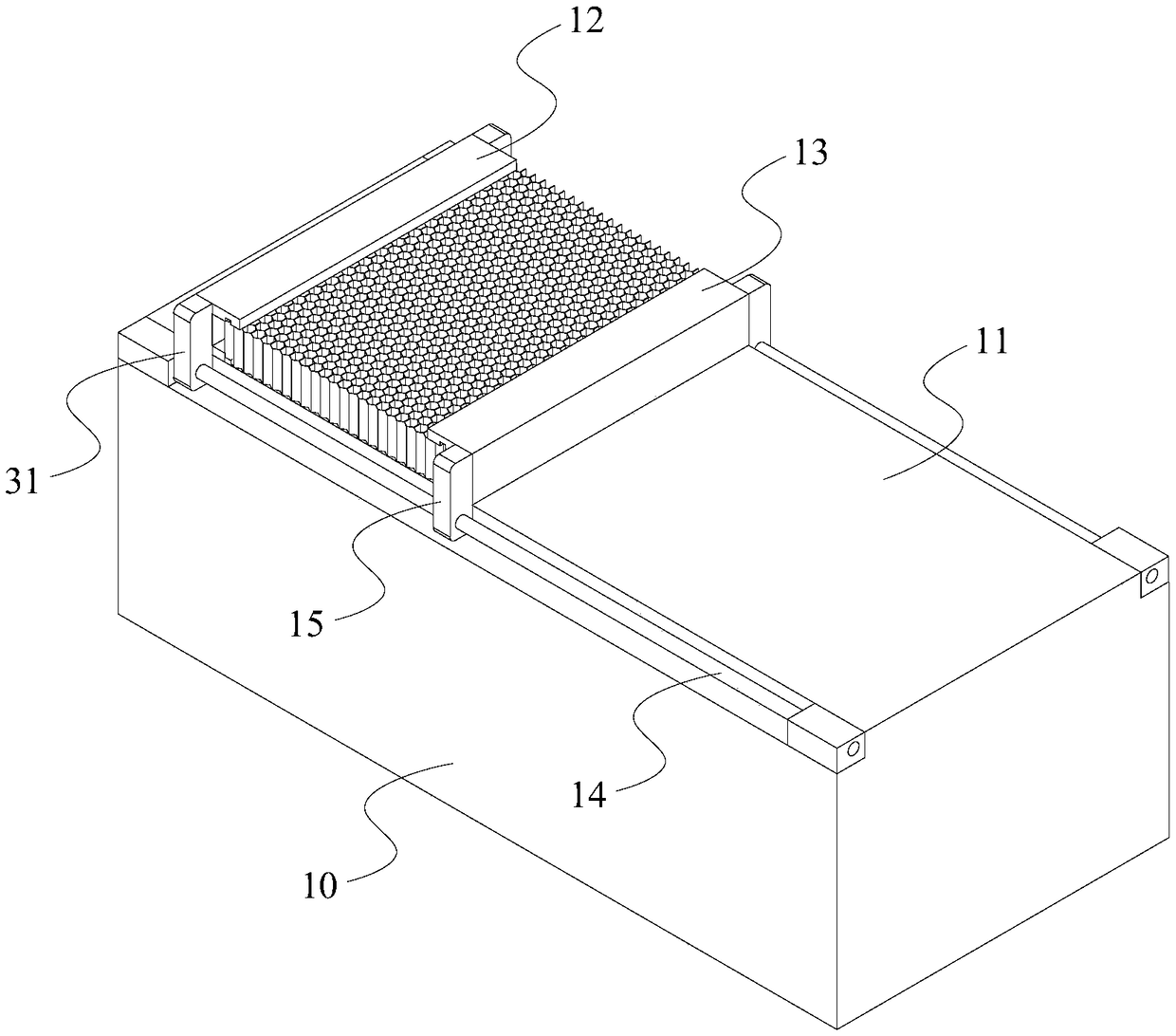

The invention provides a honeycomb material production detecting method. The honeycomb material production detecting method comprises the following steps: S01, applying tensile force in opposite directions to two opposite sides of a honeycomb bar; S02, acquiring tensile force data of the honeycomb bar in real time, and judging whether the tensile force data is consistent with pre-obtained test data or not; S03, when the tensile force data is inconsistent with the test data, regulating the size of the tensile force; S04, acquiring geometric data of the honeycomb structure in real time, and judging whether the shape dimension of a honeycomb unit in the honeycomb structure is qualified or not according to the geometric data; and S05, stopping stretching the honeycomb bar when the shape dimension of the honeycomb unit is qualified. Dynamic regulation is performed on stretching strength, a stretching distance and stretching time according to the tensile data and the geometric data acquiredin a process of stretching the honeycomb bar, so that the honeycomb bar can be stretched once to reach the needed shape dimension, and therefore, the technical problems that multi-time stretching is needed as a result of a material rebound phenomenon and the honeycomb structure is difficult to precisely control in a production process of the honeycomb material are effectively solved.

Description

technical field [0001] The invention belongs to the technical field of composite material manufacturing, and more specifically relates to a honeycomb material production detection method and equipment. Background technique [0002] At present, the commonly used honeycomb material production method is the bonding stretching method. The production process is to apply glue on the aluminum foil board at equal intervals, and then overlap and bond multiple aluminum foil boards to form a honeycomb stack. The honeycomb height needs to be cut into honeycomb strips, and then the honeycomb strips are stretched and preformed, and finally dipped, cured, and shaped to form a honeycomb material. However, in this method of producing honeycomb materials, due to the phenomenon of rebound in the stretching process of the aluminum foil plate, it needs to be stretched multiple times, or the honeycomb strip must be stretched for a certain period of time, so that the stress of the aluminum foil pl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/08

CPCG01N3/08G01N2203/0641G01N2203/0658G01N2203/0682G01N2203/0017

Inventor 李松岩刘兆晶梁志国罗昌杰孙朋周保君

Owner SHENZHEN CANSINGA TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com