Carbon nanotube composite material structural health monitoring system

A health monitoring system, carbon nanotube technology, applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, measuring devices, etc., can solve the problems of internal crack monitoring of steel structures that have not been applied in large-scale projects, Complicated data analysis and other issues to achieve the effects of life protection, excellent electricity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

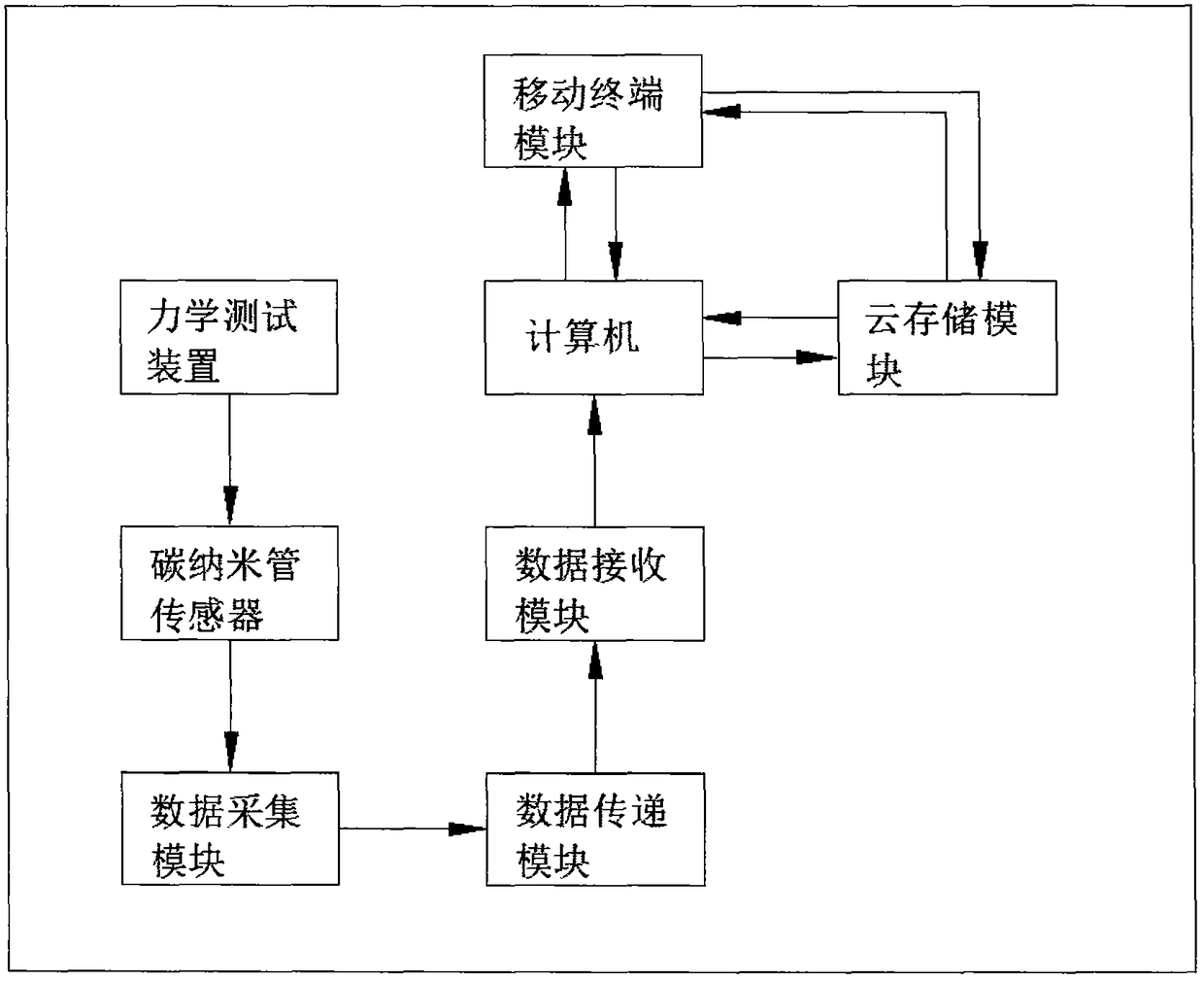

[0019] refer to figure 1 , a carbon nanotube composite structure health monitoring system, comprising a mechanical testing device, a carbon nanotube sensor, a data acquisition module, a data transmission module, a data receiving module, a computer, a cloud storage module and a mobile terminal module, the mechanical testing device The output end of the carbon nanotube sensor is connected with the input end of the carbon nanotube sensor, the output end of the carbon nanotube sensor is connected with the input end of the data acquisition module, the output end of the data acquisition module is connected with the input end of the data transmission module, and the data tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com